1. Introduction

Cross-border e-commerce, as a new trade model, is global, digital, and personalized [1]. Since 2020, COVID-19 has dampened offline consumer demand in both China and cross-border markets, but in turn raised online consumer demand, making online shopping the dominant shopping pattern. During COVID-19, cross-border e-commerce has shown a great advantage over boosting global trade. However, the cross-border sellers' supply chain has been greatly challenged. Affected by COVID-19, the supply of upstream domestic manufacturing enterprises still has not resumed work, production capacity is insufficient, and many cross-border e-commerce enterprises have no goods to sell. Under the epidemic, orders are not the same as before, coupled with the rising costs of labor, marketing, and logistics, many cross-border e-commerce sellers have difficulty running their funds [2]. Thereby stabilizing the supply chain and enhancing sustainability in case of an unexpected global public crisis has been the top priority.

As other e-commerce sellers faced difficulties resulting from COVID-19, SHEIN, a fast fashion cross-border e-commerce company, has stood out, showing the great advantage of its powerful supply chain. According to LatePost interviews, SHEIN embarked on building a supply system in 2014 when the SHEIN brand was incubated [3]. In 2019, SHEIN’s sales were close to 30 billion yuan and reached a new record during COVID-19. Although it achieved such success overseas, SHEIN was not as famous as other large cross-border e-commerce sellers at home and relevant study of its supply chain management is rare.

To fill in this gap, this paper studies how SHEIN sets and improves its powerful supply chain management by case study, and several findings are presented below. The goal is to provide practical suggestions for cross-border e-commerce sellers in China on their supply chain management. This paper is organized as follows. Section 1 provides background information about SHEIN company; Section 2 is the specific case study of SHEIN’s supply chain, including its design, production, and logistics phase; Section 3 offers suggestions on supply chain management for both SHEIN company and other cross-border e-commerce companies in China. The case study of SHEIN’s supply chain management is expected to provide ideas and practical value for other local similar companies to reestablish their supply chain and firmly occupy a certain place in the global market.

2. Background Information of SHEIN Company

SHEIN is a Chinese international B2C fast fashion e-commerce company based in Nanjing. The main positioning is fast online e-commerce, and it does not develop the domestic market, but rather exports cross-border. It is known as the "Zara of China" for its low pricing, high quality and wide range of styles. At present, it has opened branches in France, Russia, Italy, Spain, Australia, Germany, Thailand, and other places. Its business has now covered more than 200 countries and regions around the world, becoming a dark horse of fast fashion. As of May 17, 2021, SHEIN is the number one iOS shopping app in 54 countries and regions. In the United States, SHEIN's market share in the fast fashion sector jumped from 7% in January 2020 to nearly 30% in June 2021. In May 2021 alone, the mobile and PC accesses of SHEIN exceeded 150 million, 33%, 44%, and 84% more than those of Nike, H&M, and Zara, respectively.

In the competition among fashion brands, SHEIN has a clear advantage. In 2020, SHEIN completed nearly $10 billion in sales, more than twice the $4.5 billion in 2019. While SHEIN's growth is accelerating upward, the older fast fashion brands are slowing down. This is partly related to the COVID-19. Due to the COVID-19, people around the world were unable to shop at brick-and-mortar stores and turned to online shopping instead. As a result, traditional brands such as Zara and Uniqlo have seen their revenues decline, while SHEIN, which sells fully online, has seen sales soar.

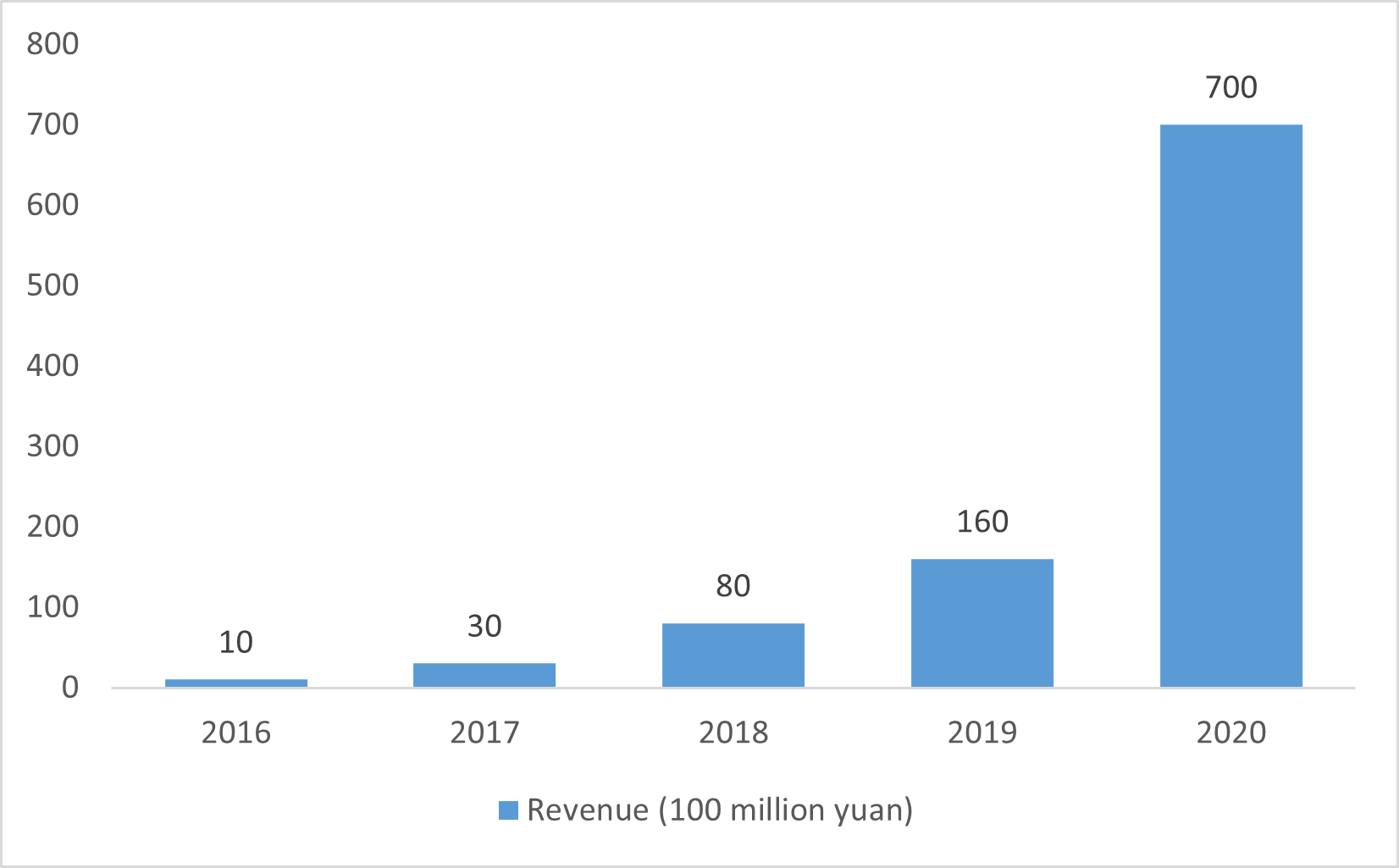

SHEIN is based on fashionable women's clothing, but not limited to this. It also continues to expand into the fields of men's clothing, accessories, home furnishings, beauty makeup and pets. Its sales scale has exploded for 5 consecutive years. As shown below in Figure 1, SHEIN's revenue growth will remain high from 2016-2019. In 2020, under the influence of the epidemic, its revenue growth further accelerated, reaching approximately $70 billion, a growth rate of over 300%.

Figure 1: SHEIN's revenue scale from 2016-2020 (Source of data: https://www.zts.com.cn)

SHEIN's success is due to its unique business model, especially its supply chain system. SHEIN relies on the advantages of the Chinese supply chain, constantly integrates industry resources and establishes a complete supply chain system, realizing production, research and marketing as a whole, SHEIN has a team of more than 100 designers and designs more than 200 new products every day. As shown below in Table 1, it takes only 2 weeks for a new product to be designed and ready to wear, which is a clear advantage over other clothing brands. And it only takes seven days for a product to go from production to sale.

Table 1: Comparison between SHEIN and other clothing brands

Comparison | SHEIN | ZARA | Traditional clothing brands |

Update cycle | Every day | Twice a week | One quarter |

Number of new products | 100,000 pieces/week | 25,000 pieces/year | 1000 pieces/year |

Speed of design | 14 days | 1 month | 6 months |

Speed of production and sales | 7 days | 3-4 weeks | 3 months |

Sales channels | All online | Online, offline | Offline |

Note: Source of data: The Wall Street Journal, https://www.zts.com.cn

SHEIN has a complete warehousing and logistics system, and the logistics arrival speed in major markets is within one week. It has 2 self-operated international sites, SHEIN and ROMWE, multi-language sites, and iOS and Android mobile apps. It has also set up five customer service management centers around the world and a customer service team of over 200 people to quickly solve problems during the purchase and after-sales process. Relying on its own strong IT technology, SHEIN independently develops IT support systems for each business backend to enhance business efficiency. Combined with the characteristics of cross-border e-commerce, SHEIN continuously optimizes its business processes to make the various business links seamless.

3. Analysis of the Supply Chain Management of SHEIN

In recent years, with the emergence of global manufacturing, the supply chain has gradually been noticed and commonly applied in the manufacturing industry as a new management pattern [4]. As COVID-19 severely paused the supply chain of China’s e-commerce enterprises in terms of cross-border business, they suffered from insufficient goods, poor logistics, higher transportation costs, and a large number of returns [2]. While foreign demand for goods online increased dramatically, China’s e-commerce sellers failed to take in all the demand. Under such circumstances, SHEIN’s distinguished supply chain has played an important role to help digest the increasing demand from overseas. SHEIN has strong supply chain discourse power and enhanced the power with digital operation throughout the whole chain. SHEIN’s supply chain contains three links: design, production, and logistics, which help the reduction of cost, the match of product style and quality, the uploading speed acceleration, and the final delivery [5].

3.1. Design Phase

SHEIN firmly holds the designing process in its hand. It has a sophisticated information system that is almost hard to reduplicate. It created different IT systems for different supply chain segments and has been capturing data to analyze consumers' needs. SHEIN grabs products from all kinds of large and small clothing retail websites, summarizing the style of current trendy products. Designers make new clothes based on the clues collected from each channel and then combine the elements. What’s more, SHEIN established its design team with 800 employees in 2016. The team's job is to design clothes quickly, make samples and send them to the factory for production. In addition, SHEIN has also established its information technology team, forming a set of algorithmic logic. The algorithm is capable of predicting the future demand for a sing unit of stock through the user's shopping preference and behavior. Equipped with the supply chain information system, SHEIN was able to quickly respond to the demand of overseas customers during COVID-19. With the help of an effective information system for capturing customers’ needs, the “zero defects” quality of products is at hand, thereby forming a competitive advantage and an entry barrier in the industry [4].

3.2. Production Phase

SHEIN established a branch in 2015 in Guangzhou, which has one of the most famous textile and fashion industry clusters in China, as well as a complete cross-border logistics infrastructure. However, most factories in Guangzhou are small and medium workshops. Although they are more flexible and suitable for the fast fashion industry than those large-scale factories which need 3-6 months to confirm orders in advance, they also have problems to handle. For example, small and medium scale means instability and weak anti-risk capability. What’s worse, small and medium workshops may close down at any time once there’s a crisis especially a global public crisis like COVID-19.

In terms of suppliers, the most important thing SHEIN did at the beginning was to be willing to support the factory. SHEIN has been supporting its foundry and grassroots suppliers to build up the "small order quick response" system. To deal with the instability nature of those small and medium workshops, SHEIN takes on the pattern-making work itself, given that most workshops are not willing to take risks accepting a small number of orders. The operation cost could be much higher than the profit. In terms of the settlement, SHEIN never fails to pay its suppliers and tries its best to increase the speed of settlement with suppliers, usually within 30 to 45 days. If the payment day happens to fall on a weekend, SHEIN will settle the bill earlier than Friday instead of postponing it to Monday. What’s more, SHEIN even lends money to factories to buy plants and upgrade equipment to help suppliers grow stronger. By supporting them in this way, SHEIN has so far developed more than 300 garment suppliers and 100 fabric suppliers. Hundreds of factories have formed an industrial cluster around it.

Except physically transforming and empowering suppliers, SHEIN also developed a Manufacturing Execution System (MES), an intelligent collaborative management system. In the production process, the MES can track the execution of each order. In the process of digitization, SHEIN sends staff to the factory to teach the use of technical tools and gives guidance and help in the management process of combing, and organizational restructuring.

3.3. Logistics Phase

The Supply Chain Center at SHEIN has invested the largest amount of manpower in the warehouse logistics department, with over 4,000 employees worldwide in the warehouse department, which accounts for almost 80% of the entire Supply Chain Center's manpower. SHEIN currently has three types of warehouses around the world, namely domestic central warehouse, overseas transit warehouse, and overseas operation warehouse. SHEIN can now deliver to more than 220 countries and markets worldwide, with support sites in the US, Spain, France, Russia, Germany, Italy, Australia, and the Middle East respectively.

To improve efficiency and keep track of inventory dynamics in real-time, SHEIN has introduced four major functions in its stocking system: inventory barcode, overlay inventory, inventory status, and external product inventory, making inventory management visualized and dynamic, analyzing inventory situation in real-time and freeing up manpower. Logistics is directly related to production costs. If the turnover rate of goods is too high or there is too much inventory backlog, logistics costs will rise sharply [6]. SHEIN replenishes stock based on big data. For example, the pop-up clothes are replenished in the order of 100 pieces based on the feedback results of the big data platform, and the pressure of inventory cleaning is small [7].

4. Suggestions on Advancing Supply Chain

SHEIN Company has successfully expanded its brand through cross-border e-commerce by grasping opportunities and under the catalysis of the pandemic environment. In recent years, through the innovation of design concepts and the recognition of new designs by young consumers in China, domestic brands have also demonstrated that they have great development space in the future. As a successful case, even in a world trade affected by the epidemic, SHEIN company has been able to make significant profits with its effective supply chain management, which shows that SHEIN Company's supply chain management has important lessons for domestic companies.

4.1. Information Sharing and Quality Management

In the post-epidemic era, the advantages of the supply chain have become increasingly prominent. Domestic companies should select suppliers and reduce the proportion of futures, and they should emphasize that the supply chain is the infrastructure for rapid product response in terms of market demand forecasting for mass apparel. Considering that domestic listed companies still rely mainly on offline channels, stores need to place their first order and cannot achieve "zero-hour sales" of SHEIN 's pure online sales. However, domestic companies can reduce inventory risk and enhance the accuracy of market demand forecasts by reducing futures and increasing the proportion of quick returns. In addition, most flexible supply chains that undertake small orders and quick responses are small and medium-sized factories. They can learn from SHEIN 's supply chain model. Brands can achieve fairness and efficiency in order distribution by selecting suppliers and continuously improving their supplier management system. Combining the improvement in the success rate of new products brought about by digital empowerment on the demand side ensures that suppliers can continuously and stably obtain orders, thereby improving the efficiency of production lines and accelerating capital turnover.

There are different aspects of supply chain management. In this part, two of them will be mainly introduced. Initially, information-sharing management is involved management in the supply chain. The rapidly developing computer technology can provide suppliers with information more efficiently. In the age of e-commerce, the relationship between producer and consumer has changed radically. As a variety of finished products appear on virtual e-commerce platforms, the differentiated needs of consumers are met to a large extent and more complex needs are developed. The simultaneous presence of various production resources on the online platform has also given producers the ability to meet the differentiated needs of consumers. As a result, the supply chain has moved from the traditional 'push supply chain' to a 'pull supply chain'. A pull supply chain is made up of the same components as a push supply chain - suppliers, manufacturers, distributors, and customers. However, the pull supply chain is customer-focused and adjusts its production plan by judging and forecasting customer demand [8]. With the power of technology in today's world, companies are using computer technology to obtain more complete information about their consumers. Computer technology can accumulate information and store it in a common database for use by companies in different business areas. Additionally, technology can quickly establish connections between suppliers and consumers, and then it can develop a logistics system that is connected and integrated with the supply chain [4].

Quality management plays an important role as well in the supply chain. Nowadays, zero-defect products have transformed from competitive advantages into barriers for new companies to enter the market. Whether in production or delivery, the quality of goods is crucial for consumers. The company should take action to avoid defective products, assigning workers to take protective measures and identifying the causes of defects, then taking action to prevent similar situations from happening in the future. Moreover, companies should pay attention to current trends and future customer needs, and they must use information systems to predict these needs. Next, companies need to find faster approaches to meet customer needs than other competitors [4].

4.2. Innovation in Logistics Service

During the epidemic, when none of the domestic logistics had fully recovered, sourcing was completely inoperable. On international logistics, the cost of small package express would rise significantly due to the reduction of flights. Therefore, sea freight would be considered, but the delivery time would be extended, which would make the consumer experience not pleasant. In this part, an innovative logistics service is suggested.

Firstly, there is the innovation of content. To better meet customer expectations, logistics management must be oriented toward customer needs, constantly innovate service content in all aspects of logistics management, provide differentiated logistics services to customers, and thus better achieve customer satisfaction [9].

The second is innovation in the way it is done. Enterprises can actively take part in logistics management operations for customers, establish effective communication channels with customers, build a good communication platform, and strive to change the traditional way of trading. They can form an interactive trading situation with mutual communication with customers, which can make a synergistic effect between enterprises and customers [9].

4.3. Product Development Orientation and Matching in Supply Chain

Cross-border e-commerce enterprises should diversify their design concepts and create more original works. More original works can bring greater brand awareness. At the same time, they can try to create high-end brands and create high premium product lines. According to the supply chain matching model [10], the utility product, the innovative product, the lean supply chain, and the fast supply chain form a quadrant. Utility products are matched to lean supply chains, while innovative products are matched to fast supply chains. For the apparel industry, clothing can generally be classified as high, medium, or low class. Now that the demand for clothing is increasingly personalized and the fashion cycle is short, SHEIN and other companies can gradually develop upscale clothing to meet the differentiated needs of consumers and to better adapt to the short-cycle nature of clothing through a fast supply chain [10].

5. Conclusion

The COVID-19 is undoubtedly a shock to the global economy, but it is also an opportunity for e-commerce. SHEIN has developed rapidly and achieved great success during the COVID-19. By studying the reasons for SHEIN's success in order to provide reference for other Chinese enterprises, this paper analyses the three stages of its supply chain, design, production, and logistics. In the design phase, SHEIN utilizes information systems to better meet customer needs. In the production phase, SHEIN fully supports the factory and establishes good cooperative relationships with suppliers. In the logistics phase, SHEIN established a visual dynamic inventory system by investing a large amount of manpower and establishing warehouse sites.

SHEIN's experience reminds Chinese companies that they should focus on supply chain management, especially information sharing management and quality management. In addition, companies should innovate the content and ways of logistics services, and match products with the supply chain. However, due to SHEIN not being listed and not disclosing its financial data to the public, the available data is very limited, and its authenticity needs further investigation. This paper only analyzes SHEIN's supply chain to a certain extent and provides some suggestions for Chinese enterprises on this basis. In addition, SHEIN's success has only been studied from the supply chain aspect, while other aspects are equally of significance, which are lacking in this paper. Further improvements should be made in future research.

References

[1]. Xu, X., Dai, M.: Research on the development of cross-border e-commerce in China under the impact of the epidemic. International Trade (02), 32-38 (2022).

[2]. Zhang, R.: The impact of COVID-19 outbreak on cross-border e-commerce sellers and countermeasures. Corporate Observer (08), 59-61 (2020).

[3]. LatePost, https://www.cyzone.cn/article/596577.html, last accessed 2023/4/15.

[4]. Prida, B., Gutiérrez, G.: Supply management: From purchasing to external factory management. Production and Inventory Management Journal, 37(4), 38–43(1996).

[5]. Wang, R.: Study of the overseas marketing strategy of SHEIN from the perspective of brand internationalization. In: Bian, L.

[6]. Xia, M.: Discussion and analysis on the flexible supply chain. China Logistics and Purchasing (02), 97-98 (2023).

[7]. Huachuang Securities: https://www.cyzone.cn/article596577.html, last accessed 2023/4/16.

[8]. Lan, B., Zheng, X., Xu, X.: Supply Chain Management in the E-Commerce Era. Chinese Management Science (03), 2-8 (2000).

[9]. Luo, H.: Research on enterprise logistics management under supply chain system. Foreign Trade (05), 108-110 (2012).

[10]. Kang, H.: The research of industry supply chain management – The comparison of the supply chain management between Lining and Uniqlo. China Academic Journal Electronic Publishing House (2014).

Cite this article

Zhang,D.;Zhang,X.;Zou,Y. (2023). Analysis on SHEIN's Overseas Success During COVID-19 from the Perspective of Supply Chain Management. Advances in Economics, Management and Political Sciences,32,137-143.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 7th International Conference on Economic Management and Green Development

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Xu, X., Dai, M.: Research on the development of cross-border e-commerce in China under the impact of the epidemic. International Trade (02), 32-38 (2022).

[2]. Zhang, R.: The impact of COVID-19 outbreak on cross-border e-commerce sellers and countermeasures. Corporate Observer (08), 59-61 (2020).

[3]. LatePost, https://www.cyzone.cn/article/596577.html, last accessed 2023/4/15.

[4]. Prida, B., Gutiérrez, G.: Supply management: From purchasing to external factory management. Production and Inventory Management Journal, 37(4), 38–43(1996).

[5]. Wang, R.: Study of the overseas marketing strategy of SHEIN from the perspective of brand internationalization. In: Bian, L.

[6]. Xia, M.: Discussion and analysis on the flexible supply chain. China Logistics and Purchasing (02), 97-98 (2023).

[7]. Huachuang Securities: https://www.cyzone.cn/article596577.html, last accessed 2023/4/16.

[8]. Lan, B., Zheng, X., Xu, X.: Supply Chain Management in the E-Commerce Era. Chinese Management Science (03), 2-8 (2000).

[9]. Luo, H.: Research on enterprise logistics management under supply chain system. Foreign Trade (05), 108-110 (2012).

[10]. Kang, H.: The research of industry supply chain management – The comparison of the supply chain management between Lining and Uniqlo. China Academic Journal Electronic Publishing House (2014).