1. Introduction to Research Background

1.1. Company Introduction

ABC is a multinational online luxury & fashion retailer headquartered in Europe. It sells directly to customers globally through its own family of multi-brand online shops; also, it has more than 800 designer brands. Now it employs over 5,000 employees with an average age of 34. Over the world, ABC has 9 distribution centers, 7 digital production facilities, 10 local offices and serves 180 countries.

We investigated the HK distribution center which is located in Tsing Yi. The distribution warehouse has two floors, and each floor has 100,000 sq.ft (including the warehouse and office). There are approximately 240 employees (full-time and part-time) in HK center, among whom are mostly secondary education level, and their communication basically relies on Cantonese.

In the HK distribution center, the warehouse manager is the top management who supervises the inbound and outbound processes as well as the work performance of inventory clerks, return clerks, pickers, and packers. The main work system that the warehouse employees use is a warehouse management system, which is installed on their Pad to prepare orders for delivery.

1.2. The Existing Problem in HK Distribution Center

In the primary investigation, we learned from one of the former employees (picker in the warehouse) that in that work environment, staff morale is low, because they face a lot of pressure in their daily work and are physically and mentally drained. Specifically, pickers have high requirements for the picking work which has a certain degree of danger, however, the company does not provide employees with benefits such as insurance but only high Key Performance Indicators (KPI). As a result, employees, especially the pickers, strsuggle to be motivated to meet all the requirements, and the company faces a high turnover rate.

2. Research Method

2.1. Interview

We interviewed 7 Warehouse department employees, including 5 employees in the picker department and 2 managers (one is the leader of the warehouse; one is the leader of the picker team). Table 1 shows respondents’ job titles and explains the two-letter codes used to identify them in text. Each code refers to an individual employee. To ensure that the views are represented centrally across the various datasets, we selected employees working at different job functions and different levels.

Table 1: Respondent’s Job Responsibilities.

Staff | Job title | Responsibility |

A | Picker department staff | Storing, taking products from the shelves, and according to the order, getting out the products to the packer department |

B | Picker department staff | |

C | Picker department staff | |

D | Picker department staff | |

E | Picker department staff | |

F | Leader of the picker team | Manage the daily work of the picker team and complete team indicators; audit and record the performance of each employee |

G | Senior manager of the warehouse | Responsible for the daily management of the warehouse; participate in the business decisions of the Hong Kong branch |

We developed a semi-structured English interview (see Appendix 1) to ask employees about four aspects: work process, work obstacles, current KPI status, and teamwork. We translate the interview protocol into Chinese and conduct interviews with employees. The interviews were mainly conducted in Cantonese as most of the staff communicated in Cantonese. We extracted consensus and feedback from 5 employees and 2 managers and searched for the factors behind the problem from their responses. We interviewed 5 pickers, we already have an intuitive understanding of the business process and found that there are already many common problems. This information is enough for further work, so we stopped interviewing more pickers.

2.2. Interview Result

According to the feedback from employees, there are often situations where the product code or shelf code is missed during the pickup process, which is a phenomenon of workaround in the current operation of the warehouse. The emergence of this phenomenon results in inconsistent records between the goods and the system, and employees have to spend a lot of time on the way to find the ordered goods. At the same time, it faces the institutional risk of loss of goods. The reason for this phenomenon, to a large extent, comes from the performance pressure brought by employee performance indicators to employees, and the lack of business cooperation in the warehouse outbound management system.

In addition to the problem of workaround, part of the network of shelves in the warehouse is often disconnected; the management only speaks English, and the problem of poor communication with the employees of the picker department hinders their communication with the business. Both issues also affect employees’ work experience.

Overall, employees are not very satisfied with their work here. On the one hand, there are pressures brought about by high performance, and on the other hand, there are problems such as lack of welfare guarantees. Low employee satisfaction may be an important reason for the high turnover rate of employees in ABC company’s warehouse.

From the managers’ point of view, the performance of ABC, Company’s Hong Kong branch has always been the highest among all the companies, thanks to the huge Hong Kong market and the high work efficiency of its employees. But at the same time, he is also aware of the work pressure brought about by high performance, resulting in a high turnover rate of employees, and the cost is higher than the benefit in the long run. As for the warehouse management system, he also believes that it is slightly different from the business process, but this system is required by the head office and cannot be replaced in the short term. For the idea of improving the efficiency of warehouse work, he is more concerned about the implementation cost of the measures and tries to optimize it in a way that does not involve major renovations.

2.3. Literature Research

In addition to the interview, we also established a comprehensive understanding of the on-site workflow through internal instruction manuals and video viewing of the on-site workflow.

After sorting out the problems existing in the warehouse process, for the solution of the follow-up problems, we combine the opinions of employees, through extensive research work around related literature and understanding literature related to smart warehouses, to sort out the improvement direction for the current problems in the warehouse, to get optimization measures in subsequent chapters.

3. Diagnosis of the Situation

3.1. Current Goods Inbound and Outbound Process

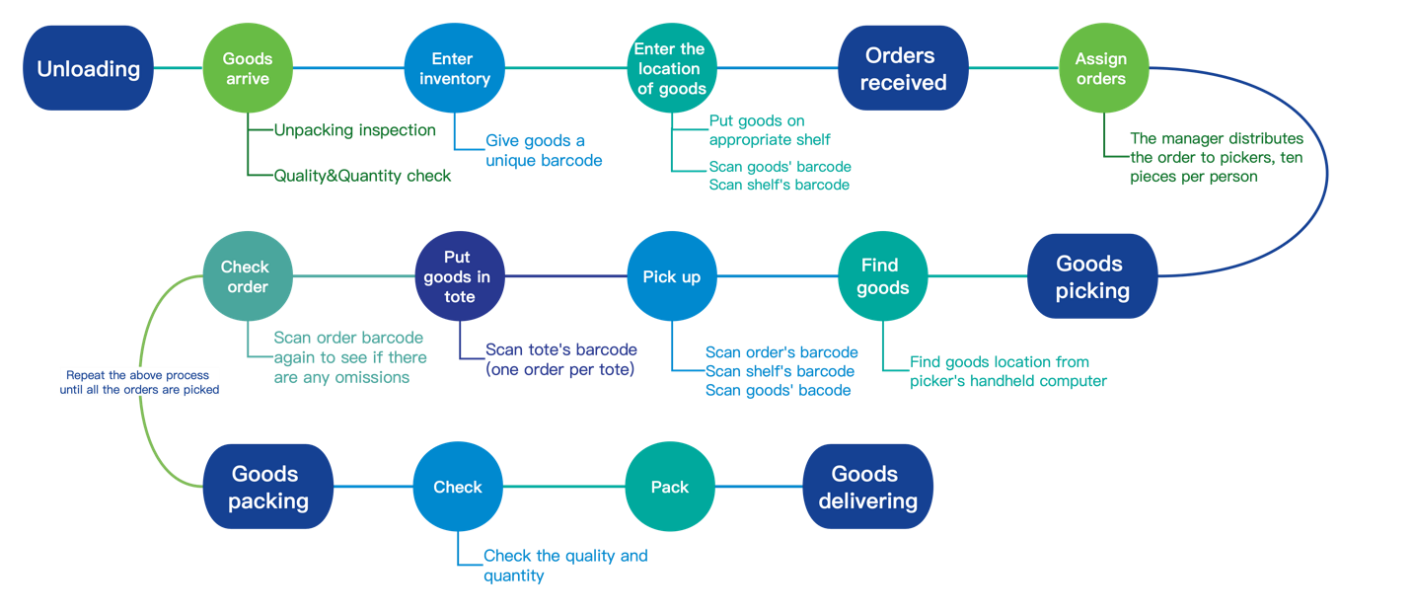

Figure1: Current process of inbound and outbound.

Unloading

After the goods arrive, the warehouse workers will unpack the goods, check the quantity and quality, attach a unique barcode to each commodity and enter the inventory. Then workers put the goods into the totes on the appropriate shelves, before scanning the barcode of the goods and the barcode of the location of certain goods. Finally, complete the process of entering the commodity location data into the cargo management system.

Order received and goods picking

When the warehouse manager receives the orders from the customer service department, he assigns the paper version order to pickers, ten pieces per person per time. Then the picker will push a cart to find around the warehouse and pick up goods. Each cart can only hold 4 totes, each tote can only hold one order of goods. During the pick-up process, pickers must first check the location and inventory of the goods in the system. The picker needs to plan the pick-up route by himself. After finding the goods, pickers will scan the barcode of the order, then scan the barcode of the shelf, then scan the barcode of the goods, and finally put the goods into the tote corresponding to the order, then scan the barcode of the tote to complete the pick-up process. After picking up all the goods in the order, they will scan the order to confirm whether there are any omissions.

Packing and delivery

After picking the goods for all the orders, pickers will hand over the totes with the goods and the orders to the packers, who will check the quality and quantity of the goods, and then pack them and finally deliver them to customers.

3.2. Work System Snapshot

WMS is a module of ABC company’s entire Enterprise Resource Planning (ERP) system in the warehouse system. As part of the global company strategy, it is used to standardize the warehouse management mode and unify the goods picking process. The strategy calls for the WMS to support and integrate all warehouse cargo management activities. As Table2 shows in the working system snapshot, these processes include customer order processing, goods sorting, order delivery, and more.

Table 2: Work Systems Snapshot of ABC WMS.

Customers | Products & Services | ||

• End customers • Suppliers • Warehouse managers • Customer service • Delivery contractors | • Provide replacement and replenishment information to suppliers • Provide order/goods status data to customers • List customer order details for managers • Provide product location and inventory data to pickers | ||

Work Practices (Major Activities or Processes) | |||

Work Process | |||

• Customer service creates customer orders and sends them to WMS. • The warehouse managers receive the orders and assign them to pickers. • Warehouse pickers determine order requirements; search the goods location and inventory level from WMS; scan the barcode to complete goods picking. • Warehouse packers double-check the quality and quantity of goods using WMS. • The delivery team extracts data from WMS, plans for delivery capability, and creates a delivery list. • Customers receive the order progress information | |||

Activities related to Coordination of workaround | |||

• All staff, particular team leaders, functional managers, and supervisors need to meet the design, coordinate, and confirm workaround arrangements that apply to many processes in the HK warehouse. • All staff coordinate/ share information across the customer service department and the warehouse using pad, email, WhatsApp and share drives. | |||

Participants | Information | Technologies | |

• Warehouse manager • Warehouse pickers • Delivery team • Customer service | • Customer order • Inventory level • Goods location • Replenishment order • Deliveries | • WMS • Pad • Share Drives | |

3.3. Workarounds: Why and How

We interviewed 5 pickers who account for approximately 25% of the picking team resources. Through the interviews, we learned that the Hong Kong company of ABC has set up a KPI that a picker needs to collect more than 30 items per hour. If the pickers fail to meet this requirement, they will receive a mild warning for the first time. If they keep receiving such warnings for more than 3 times, they will be faced with more severe penalties such as re-training and allowance deduction.

According to our interviews with two warehouse managers, ABC has established standardized procedures for online order delivery, which are summarized in the work system snapshot above.

Though the procedures are standardized and applied to all ABC’s distribution centers, we learned that the KPI is not consistent among the 9 locations. The KPI set up by the Hong Kong company is the highest. The major reason is that the Hong Kong distribution center is the busiest one. The problem is that it is almost impossible for the pickers to meet this KPI requirement if they completely comply with the standardized procedures. Therefore, the former senior management of the Hong Kong distribution center devised some workarounds that enables the pickers to reach the high KPI requirement. All the new pickers will be trained with the new workflow during the probation period.

As per the original standardized procedures, all the items of an order must be placed in a single tote basket in case different orders are messed up. That’s why a picker should scan the barcode of the tote bag after collecting an item. The rolling cart assigned to the pickers can accommodate 4 tote baskets at maximum, which means they can process 4 orders at the same time. In practice, the leader of the picker team assigns 10 purchase orders to a picker at a time. Then the workarounds begin here. First, the pickers will put 10 tote baskets on the rolling cart to process 10 orders at a time instead of 4. Second, they will take advantage of a bug of the ERP system. After getting an item off the shelf, they do not scan the barcode of the tote basket as before. Rather, they will scan the barcode of the order one more time to create a virtual tote basket.

In the ERP system, both the purchase order number and the tote basket number coincidently contain 7 digits. Since every order number is unique, by scanning the order barcode they can create a unique tote basket number, and thereby linking every item to the exclusive tote basket it belongs to. There is another benefit due to the workarounds. Since the corridor between shelves is very narrow and congested, it’s very inconvenient for the pickers to bring along the heavy rolling cart while browsing the shelves. As they do not need to scan the tote basket anymore, they can just leave the cart right in front of the area where they collect the items. This can save both time and energy. After collecting all the items of the 10 orders, the pickers pass the tote baskets to the packers for pre-delivery check.

3.4. Assessment of Workarounds

Non-compliant behaviors devised by employees are not necessarily problematic. In fact, we found that there are both pros and cons of the workarounds in this case, which are summarized as follows:

Pros:

Workarounds can enhance work efficiency (i.e., the number of items collected per hour), thereby saving labor cost for the organization. By creating virtual tote baskets, the pickers no longer have to bring the physical tote baskets with them when traveling from one area to another to collect items, which is a successful adaptation to the Hong Kong warehouse with inadequate space.

Cons:

(1) Despite higher overall efficiency, manual mistakes often occur due to too many orders being handled at the same time (e.g., an item is dropped on the ground by accident and then the pickers do not know where to find it when they are aware of the situation).

(2) The rolling cart loaded with 10 tote baskets is too heavy and may cause danger to the pickers. Remember that the Hong Kong company does not provide accident insurance for its part-time employees.

Problems:

(1) Redundant pickup process. The picker will scan a lot of codes during the work process. During this process, the work process and information update may be out of sync due to the picker’s personal problem or network problem.

(2) The pickup efficiency is low. At present, the working interface of picker’s handheld pad only displays order-related products and product location information, and plans the pickup route by itself, which reduces the pickup efficiency to a certain extent.

(3) Unreasonable KPIs lead to high employee turnover. Managers set KPIs that are slightly higher than the highest achievable by current workflows. In addition, the actual workflow does not match the work system, and pickers can only complete KPIs through their own workarounds. Excessive KPIs cause their physical and psychological pressure, and the employee turnover rate is high.

4. Consideration of Alternative Actions That Could Be Taken

4.1. Introducing Personal Digital Assistant (PDA)

PDA is called the Personal Digital Assistant. The solution discussed by our group is that each picker in the warehouse carries a handheld device (PDA)to scan the code (One- and two-dimensional bar codes). New versions of PDAs on the market now have computing, telephone, and Internet functions, like smartphones. Here are some of PDA’s main functions used in the warehouse.

Firstly, it can scan bar codes attached to goods. Bar code technology can be used for the automatic collection and identify commodity information by PDA and warehouse information systems[1]. PDA devices’ information input speed and accuracy are high and can collect a large amount of information about goods. In addition, it is more convenient and flexible for pickers to carry in warehouse activities. And bar code label is easy to make, identification equipment’s operation is simple for pickers and relatively cheap. We believe these functions used in the warehouse have a strong practical and ease of use.

Secondly, it has the WIFI 802.11b/ G/N function. This is the mainstream technology of wireless LAN, 802.11b/g/ N can be used for wireless data exchange with PC and server in a larger enclosed space, so this function is also applicable in the company’s warehouse, and the transmitted data is stored in WMS. So, these functions are efficient enough for ABC to share goods information in the operation process.

4.2. Updated Warehouse Management System (WMS)

Based on cost and budget considerations, we believe that the company’s WMS can be connected to some communication technologies, such as bar codes, mobile computers, etc., to store and process transaction information. These devices are not expensive on the market. We believe ABC can introduce the following four modules as the four main functional parts of the warehouse management system.

4.2.1. The Management of Inbound Goods and Inventory Management

Warehouse information department staff need to input the contract information signed by customers into the system, including contract number, customer number, customer name, start date, cost information, etc. Responsible employees can view the specific information and situation of goods in the storage management system, and the specific total amount of goods in storage. At the same time, the management can also see the information about the goods in the warehouse on this page. In addition, warehousing goods need to be put on the shelf during the process, warehousing management system also has shelf management and quality management functions.

Inventory management is also important during the period before goods are shipped out of the warehouse. Because all the information about the goods in storage is recorded in the system, the staff can inquire about the inventory surplus, and the system can provide the function of a low inventory warning, which is convenient for the warehouse to replenish goods in time [2].

4.2.2. The Management of Outbound Goods

After the picker scans the bar code of the goods (explain more on that in the next section), the information of the goods will be transmitted to the outbound system part through the mobile terminal, and the corresponding employees can track and query the location of the goods in time. The page is like the inbound part. The staff can handle the removal of goods from the shelves, the status of the shelves and the emergency goods out of the warehouse inquiry.

4.2.3. Basic Information Management

The supervision and management of some basic information is also an essential part of the normal operation of the warehouse. This basic information includes the personal information of each member of staff, warehouse employers, warehouse communications equipment and machinery, and shelf query. Management can view the hardware and software information and usage of the warehouse at any time.

Combined with inbound and outbound management, inventory and basic information management, we believe that the company’s warehouse can query timely and manage the information of goods, shelves, personnel, and equipment information well.

4.3. Ultra Wide Band (UWB) Positioning Technology and Path Planning

The picking road length is the distance that warehouse personnel need to travel from the start of each order to the completion of each order during the picking operation, factors that ultimately affect the length of the picking road are the picking speed and picking time. The design of the picking path is directly related to the length of the picking path and choosing the best picking path plays an essential role in improving overall efficiency. It is not just simple factors such as personnel strength that affect picking efficiency [3]. It also includes essential conditions such as the design of the picking path and the degree of optimization of the storage location. The optimization method of the picking path refers to how to enter the next channel most shortly after the goods in one channel are picked and calculated. After entering the next channel, the goods in the same channel will be picked first and which will be picked later, thereby reducing the Invalid round trip.

There are no optimal options for picking routes and methods, only the most suitable options. Reasonable and scientific picking routes and picking methods can significantly improve picking efficiency and reduce the workload of pickers. The picking routes and picking methods are based on shelves, commodity placement, and identification due to the limited storage of goods in the small warehouse and limited shipments.

When the warehouse introduces Ultra Wide Band (UWB) high-precision positioning technology, it can be integrated with the warehouse management system (WMS) to form a warehouse indoor positioning system and path planning. And the positioning technology can display real-time trajectory information of goods. In addition, the warehouse indoor positioning system can combine the location information of goods with the video screen through linkage with warehouse monitoring video. Therefore, path optimizations based on the UWB technology will give pickers direct information like step-by-step advice on how to get eight orders’ goods as quickly as possible.

4.4. Unmanned Warehouse

After investigation and discussion, we believe that an unmanned warehouse would be a solution. The unmanned warehouse includes the entire process of goods from warehousing, storage, packaging, and sorting and truly achieve intelligent unmanned operation. However, to fully realize the distribution of goods, large warehouse space is needed, and robots can operate only by relying on such a vast venue. Investing in an unmanned warehouse requires a large budget, not only for the site but also for the equipment. Hong Kong is a place where every inch of land is expensive. From the perspective of site factors, unmanned warehouses are not suitable for the Hong Kong company. For unmanned warehouses, conveyor belts are also a basic configuration. It cannot meet the space requirements of long conveyor belts in a narrow space. Robots are indispensable for unmanned warehouses. However, the cost of robots is high, and the maintenance costs in the later period are also high, which is not in line with the financial status of the Hong Kong company. In addition, once the unmanned warehouse is introduced, many employees will face unemployment, which is irresponsible behavior for management. Based on the above comparison and discussion, the unmanned warehouse solution is not suitable for the Hong Kong company.

4.5. The Change in KPI

KPI is the decisive factor for completing a particular task and being competent for a specific position. It is a measurement standard set based on the job responsibilities closely related to the employee’s work, reflecting the position’s work focus. According to the current situation, the business of Hong Kong company is the best, so the relative KPI formulation is also higher. At present, the KPI set by the Hong Kong company for each picker is to pick up 30 items per hour. The picker of Hong Kong company has regular employees and probationary employees. Probationary employees have the same KPIs as regular employees. If the picker fails to meet the KPI during the probationary period, they cannot become a regular employee. For regular employees, if the KPI of the day does not meet the standard, the salary will be deducted. If the KPI fails to meet the standard three times in one month, it may risk buckle bonuses.

The formulation of this KPI is relatively high for employees. The pick-up volume of 30 goods per hour will undoubtedly cause more significant psychological pressure on employees, and it is also not conducive to physical health. Frequent pick-up, high-intensity work, and constant search in the warehouse make the pick-up staff very tired. Employees will pick up to 10 totes per hour to meet the KPI., employees’ physical and mental health is not guaranteed, resulting in the loss of personnel. Due to the high KPIs set, the turnover rate is high. That makes Hong Kong company has many costs in labor. Due to the continuous flow of personnel, it will continue to recruit new people, thus will continue to have the cost of training new employees, which is time-consuming and laborious.

Adjusting the KPI to a lower standard may be a solution. The adjustment of KPIs can relieve employees’ physical and mental pressure to a certain extent, thereby reducing the resignation rate and reducing the company’s labor costs.

5. Recommendation of Specific Actions to Take

By introducing the techniques mentioned above, pickers will be able to streamline their workflows and the work process will become more efficient. This section describes how they apply new techniques to their work process.

5.1. Pickers’ Inbound and Outbound Goods Process Based on PDA, WMS, and UWB Positioning Technology

To make it more convenient for the pickers, we replaced the original handheld device with a PDA that includes customized paths, inventory quantities, and order details. The picker will pick up goods according to the route guided by the UWB positioning technology within PDA and scan the code to check the goods through the PDA during the pick-up process.

5.1.1. About the Inbound Process

After the goods are delivered to the warehouse by the supplier, pickers need to use PDA scanning to put the goods in storage. The staff will check the commodity information. After checking, the commodity information will be input into the warehouse management system. Workers will print out corresponding labels of corresponding goods through the system and paste them on all goods. After the system audit is completed, the system will assign the location of the goods according to their different attributes.

When pickers find corresponding shelves and items, they simply scan the bar code on the item instead of scanning codes on shelves, touts, and orders code. Those three types of barcodes are no longer needed. Because the network in the warehouse is not good and scanning code process is complex, the picking process is not efficient. The upgraded barcode scanning process reduces the scanning procedure and greatly improves efficiency for pickers. Warehouse staff only need to place the goods on the corresponding shelf position according to the system prompts. The storage system will automatically update the inventory information and record the dynamic changes in the inventory.

5.1.2. About the Outbound Process

The outbound process is like the inbound process. Pickers can look up the location information of items in the order in the WMS and send orders’ information to the PDA so that they can view items’ information at the beginning of the pickup process. Pickers will see the detailed location information of eight orders on PDA and use the positioning system and path planning function to intuitively see the optimal route planning guide and carry out walking navigation which is very similar to the map navigation we usually use to go to unfamiliar places. The positioning system can realize the intelligent visual management of goods in the warehouse and realize the structured intelligent storage management mode of goods from inbound warehousing to outbound warehousing. The same applies to goods moving, searching, and other processes using the UWB positioning technique[4]. And it will optimize the efficiency of material scheduling and increase the utilization rate of the warehouse.

Pickers then scan the barcode in the goods and goods information like which product of which order has been picked will appear in the PDA, and staff will take goods belonging to every eight orders into touts and pass them to packers, who will check items’ quality, check the information, and transfer them to the waiting area and prepare to release the goods from the warehouse

5.2. Adjusting KPI

Along with the addition of sound technical operations, Hong Kong Company can adjust its KPI to help the company accomplish better improvements. The purpose of setting up a KPI is to motivate employees and reach the company’s strategic goals. In order to reduce the employee turnover rate and protect the physical and mental health of employees. We recommend that companies should pay attention to balancing KPIs and employee interests. According to the KPI settings, the original employees will do ten order tasks at a time to complete the KPI of 30 items per hour. Because the cart that carries the goods is heavy, it is challenging for the employees to push the cart after picking up ten sheets of goods. Now reduce the KPI standard to 80% of the original and set the KPI to 24items per hour. To better implement KPIs and relieve the pressure on pickers, the company can retrofit the trolley to a capacity of 8 handbags at a time.

6. Expected Outcomes of the Intervention

In general, in order to solve the problems of high employee turnover and workarounds in ABC’s HK distribution Center, we propose a comprehensive intervention plan with the expected effects as follows:

In terms of system, the original warehouse management system has integrated and optimized four modules including inbound information management, inventory monitoring, out bounding scanning process and order allocation management of employees. For pickers, their workflow got smarter. There is no need to repeatedly scan the code for order, tote, shelf, and goods, but to quickly pick goods through the route planned by the system. The operating time and the time for manual route planning are reduced, and the work efficiency of employees will be significantly improved[5].

In terms of equipment, the original handheld device is replaced with a PDA scanning device to achieve faster outbound information transmission and more accurate inventory monitoring, reducing the error rate of picking. In addition, the previous cart that can only accommodate 4 totes will be upgraded to a cart that can accommodate 8 totes, increasing the safety of employees when dealing with multiple orders at the same time.

In terms of employee management, according to the original KPI requirements and employee needs, the KPI requirements have been adjusted to reduce the work pressure on employees.

7. Conclusion

In this project, our team learned lessons from these aspects:

First, for the management, it is necessary to observe the working status of employees and communicate with them, not just care about the final output of the team. If the company only formulates rules and evaluates employees based on performance, it will cause employee dissatisfaction, resulting in a tense working atmosphere, negative work attitudes, and even the company will face the pressure of employee turnover.

Second, for employees, if they face unnecessary pressure at work, or the actual work cannot meet the requirements of the company, they also need to actively communicate with their superiors and jointly negotiate a reasonable solution.

Third, workarounds sometimes don’t seem to be harmful to the company, which is the result of the team’s adaptation to the company’s rules. However, due to the mismatch with the standard process, various problems are prone to occur in the work.

References

[1]. Zhang Jinjin, (2018), Application of PDA and bar code technology in electric power material management.

[2]. Paul, S., Chatterjee, A., & Guha, D. (2019). Study of smart inventory management system based on the internet of things (IOT). International Journal on Recent Trends in Business and Tourism (IJRTBT), 3(3), 27-34.Ang M, Lim Y F (2019). How to optimize storage classes in a unit-load warehouse. European Journal of Operational Research, 278(1): 186–201 https://mathscinet.ams.org/mathscinet-getitem?mr=3950576

[3]. Aldarondo F J, Bozer Y A (2020). Expected distances and alternative design configurations for automated guided vehicle-based order picking systems. International Journal of Production Research, in press. https://doi.org/10.1080/00207543.2020.1856438

[4]. Frankó, A., Vida, G., & Varga, P. (2020). Reliable identification schemes for asset and production tracking in industry 4.0. Sensors, 20(13), 3709.https://doi.org/10.3390/s20133709

[5]. Amato F, Basile F, Carbone C, Chiacchio P (2005). An approach to control automated warehouse systems. https://www.sciencedirect.com/science/article/abs/pii/S0967066104002345

Cite this article

Yan,X. (2024). The Consulting Research of ABC Warehouse. Advances in Economics, Management and Political Sciences,72,137-147.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Management Research and Economic Development

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhang Jinjin, (2018), Application of PDA and bar code technology in electric power material management.

[2]. Paul, S., Chatterjee, A., & Guha, D. (2019). Study of smart inventory management system based on the internet of things (IOT). International Journal on Recent Trends in Business and Tourism (IJRTBT), 3(3), 27-34.Ang M, Lim Y F (2019). How to optimize storage classes in a unit-load warehouse. European Journal of Operational Research, 278(1): 186–201 https://mathscinet.ams.org/mathscinet-getitem?mr=3950576

[3]. Aldarondo F J, Bozer Y A (2020). Expected distances and alternative design configurations for automated guided vehicle-based order picking systems. International Journal of Production Research, in press. https://doi.org/10.1080/00207543.2020.1856438

[4]. Frankó, A., Vida, G., & Varga, P. (2020). Reliable identification schemes for asset and production tracking in industry 4.0. Sensors, 20(13), 3709.https://doi.org/10.3390/s20133709

[5]. Amato F, Basile F, Carbone C, Chiacchio P (2005). An approach to control automated warehouse systems. https://www.sciencedirect.com/science/article/abs/pii/S0967066104002345