1. Introduction

This essay is going to talk about the advantages and disadvantages, efficiency and other parts to compare spark-ignition engine and electric motor. Spark ignition engine is a type of internal combustion engine in which the air-fuel mixture is ignited using a spark from the spark plug [1]. Now, More and more electric vehicles appear in many countries, it seems better than traditional car (spark-ignition engine car/ petrol car). But whether the electric vehicles have much more advantages than traditional cars? The history of spark-ignition engine is begun from the ancient engine, which is like a fire piston (diesel engine). Till 1807, the first engine was invented.

From ancient times, the earliest engines were simple devices such as the steam engine invented by Hero of Alexandria in the 1st century AD, which used steam pressure to create motion. In medieval Period, the invention of the crankshaft in the medieval period led to the development of hand-cranked engines for various applications.

When industrial Revolution started, in 18th Century: The Industrial Revolution brought significant advancements in engine technology. James Watt’s improvements to the steam engine in the 1760s made it more efficient and practical, leading to its widespread use in industries such as mining, manufacturing, and transportation. Internal Combustion Engines is invented in 19th Century. And the invention of the internal combustion engine revolutionized transportation. In 1860, Étienne Lenoir built the first practical internal combustion engine, which used coal gas as fuel. Nikolaus Otto developed the four-stroke engine in the 1870s, followed by Rudolf Diesel’s invention of the compression-ignition (diesel) engine in the late 19th century.

Automotive Engines is produced in late 19th Century. Karl Benz and Gottlieb Daimler independently developed the first practical gasoline-powered automobiles in the 1880s, using internal combustion engines. In early 20th Century, to make cars more affordable and accessible to the masses, Henry Ford’s mass production techniques and assembly line revolutionized automobile manufacturing, [2].

In world War II Era, jet engine is invented. The development of jet engines marked a significant milestone in aviation technology. Frank Whittle and Hans von Ohain independently invented jet engines in the 1930s, leading to the first operational jet-powered aircraft during World War II. Modern Engines means the engine that is invented in the late 20th Century. The advancements in electronics, materials, and engineering techniques led to the development of more efficient and environmentally friendly engines such as turbocharged engines, hybrid engines, and electric motors [2].

The Ongoing Developments means Modern engine technologies continue to evolve, focusing on reducing emissions, improving fuel efficiency, and exploring alternative fuels and power sources like hydrogen fuel cells and electric propulsion systems.

2. Advantages and disadvantages

A spark-ignition engine operates by burning a fuel-air mixture within a combustion chamber. First, it relies on the combustion process to generate high-pressure gases that drive the piston, converting the chemical energy of the fuel into mechanical work. Second, the engine requires a spark plug to ignite the fuel-air mixture. Third, speak-ignition engines typically consume liquid or gaseous fuels such as gasoline, diesel, or natural gas. Fourth, speak-ignition engines produce emissions such as CO2, NOx, CO, and particulate matter during combustion. Fifth, spark-ignition engines have been widely used fin conventional vehicles for many years [3].

An electric motor operates based on electromagnetic principles. First, it converts electrical energy into mechanical energy to produce rotational motion. Second, Electric motors consist of coils wound around a magnetic core. When an electric current passes through the coils, it creates a magnetic field that interacts with permanent magnets, resulting in the rotation of the motor shaft. Third, Electric motors require a power source, typically in the form of a battery, to provide the electrical energy. Fourth, electric motor does not burn fuel internally, and therefore, do not produce tailpipe emissions at the point of use.

3. Efficiency

3.1. Calculation of spark-ignition engine efficiency

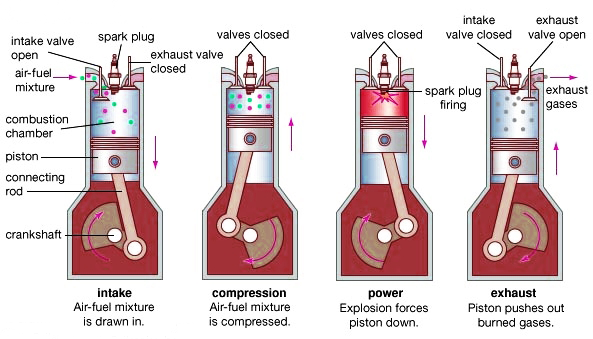

Figure 1 shows how spark-ignition engine work, namely the four steps of the work of spark-ignition engine [4].

Figure 1. Four steps of works of spark-ignition engine.

Priming (intake) process means the piston moves downward from the top of the cylinder to the bottom while the intake valve opens. This creates a vacuum that draws in a mixture of air and fuel into the combustion chamber. Compression process is the piston moving upwards, compressing the air-fuel mixture within the combustion chamber. The temperature and pressure of the mixture are increased by the compression. Operation (power) process means when the piston reaches the top of the compression stroke, a spark plug ignites the compressed air-fuel mixture. The ignited mixture rapidly burns, creating an explosion. This explosion generates high-pressure gases that push the piston downward, creating mechanical work. The power generated during this stroke is used to propel the vehicle or perform other tasks. Emission (exhaust) process is the last step of spark-engine’s work. The piston moves back up, release the burnt exhaust gases out of the combustion chamber through the open exhaust valve. After the exhaust stroke, one cycle completes, preparing the engine for the next cycle. After understanding the principle of spark-ignition engine, people can find out ways to calculate the efficiency of spark-ignition engine.

Efficiency(t)=Indicated Power / Fuel Energy

Efficiency(t)(%)=Indicated Power(KW)*3600*100/ Fuel Flow(Kg/Hr)*Calorific Value(KJ/Kg)

These show the functions to calculate the efficiency: indicated thermal efficiency (ηt) means indicated thermal efficiency is the ratio of energy in the indicated power to the fuel energy. To calculate the efficiency of spark-ignition engine, it is necessary to know the indicated power and fuel energy, also can be understood as total output energy and total input energy.

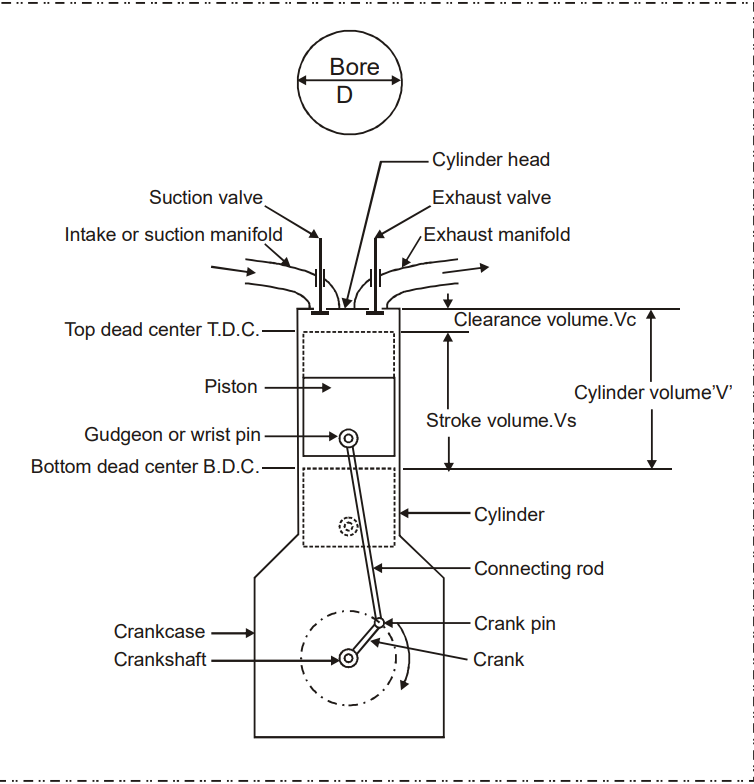

Figure 2. All names of the appliances of spark-ignition engine.

Then the author will talk about how some of the appliances work in calculating the efficiency of spark-ignition engine. Engine Cylinder diameter (bore), which is the nominal inner diameter of the working cylinder. Piston area is the area of a circle of diameter equal to engine cylinder diameter. The way to calculate is 2*area / 4 diameter. Engine Stroke length is the instance through a working piston moves between two successive reversals of its direction of motion. Dead center is the position of the working piston and the moving parts, which are mechanically connected to it at the moment when the direction of the piston motion is reversed [5].

3.2. Two-stroke cycle engine

A two-stroke cycle engine, also can be called a two-stroke engine, is an internal combustion engine that completes a full power cycle in only two strokes of the piston. It differs from a four-stroke engine. Here’s how a typical two-stroke cycle engine works. Compression or Combustion Stroke work in this way, as the piston moves upward, it compresses the air-fuel mixture present in the crankcase. Simultaneously, the spark plug ignites the mixture, initiating combustion. The expanding gases from the combustion force the piston downward. Exhaust or Intake Stroke work in this way, as the piston reaches the bottom of its stroke, it uncovers the exhaust ports or valves, allowing the burned gases to escape. At the same time, fresh air-fuel mixture (previously stored in the crankcase) is drawn into the combustion chamber through ports or valves located near the cylinder head. The two-stroke cycle engine relies on the lower part of the piston to act as a scavenging pump, pushing out the remaining exhaust gases and drawing in the fresh air-fuel mixture. This scavenging process occurs simultaneously with the compression and combustion stroke. There are some features of two-stroke engine, such as two-stroke engine has fewer moving parts compared to their four-stroke counterparts, making them relatively simpler in design and construction and two-stroke engines tend to be less fuel-efficient than four-stroke engines because a portion of the fresh fuel-air mixture can escape through the exhaust ports before combustion and due to their compactness and direct power delivery per revolution, two-stroke engines can provide higher power output relative to their weight and most two-stroke engines require the addition of lubricating oil to the fuel, as there is no separate oiling system, the oil helps lubricate the engine’s moving parts and is typically mixed with the fuel at a specified ratio [6].

4. Emissions

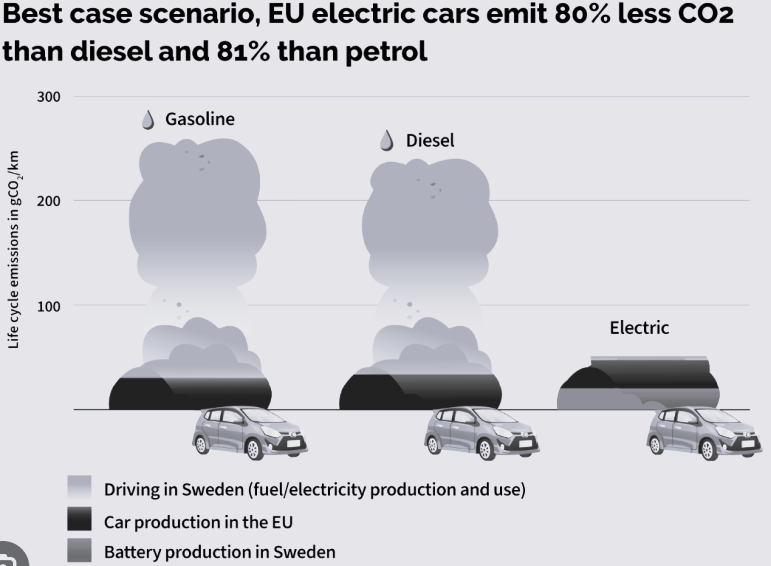

Burning gasoline will release greenhouse gases. Spark-ignition Engine Power Generation means the power generated by a spark-ignition engine is typically measured in horsepower (HP) or kilowatts (kW). The power output of a spark-ignition engine can vary depending on factors such as engine size, design, fuel type, and efficiency. In automotive applications, small passenger cars may have spark-ignition engines with power outputs ranging from around 70 HP (52 kW) to 200 HP (149 kW), while high-performance vehicles or larger engines can exceed several hundred horsepower [7].

Figure 3. Electric motor will not produce any harmful gases.

Electric Motor Power Generation means electric motors’ power output is measured in kilowatts or sometimes in horsepower (HP) for comparison. The power output of an electric motor depends on various factors such as the motor’s design, construction, voltage, and current. Electric motors used in automotive applications can range from tens of kilowatts for small electric vehicles to several hundreds of kilowatts for larger electric vehicles or high-performance electric sports cars.

5. Noise and vibration

5.1. Spark-ignition noise

The primary noise generated in a spark-ignition engine is the combustion noise resulting from the rapid and controlled explosion of mixture of air fuel inside the cylinders. This creates a characteristic “popping” or “knocking” sound, especially under heavy load or at high engine speeds. Excessive detonation or knocking can be a sign of improper fuel/air mixture or engine-related issues. When the engine draws in air through the intake system, a whooshing or sucking sound can be heard (Intake Noise). This noise is more noticeable when the throttle is wide open, such as during hard acceleration [8].

Exhaust Noise, as the gases that combustion releases exit the engine through the exhaust system. The engine generates an audible noise. This noise can vary depending on the design of the exhaust system, including the presence of mufflers and resonators. Some performance-oriented vehicles may have a louder, sportier exhaust note. Valve Train Noise, the movement of the valves and their interaction with the camshaft and other components can produce clicking or tapping sounds. Proper valve adjustment and regular maintenance can help minimize excessive valve train noise.

Belt and Pulley Noise is created by Ancillary components such as belts, pulleys, and tensioners rattling or squeaking noises if engines are worn out or improperly tensioned. Regular inspection and maintenance of these components are necessary to prevent noise-related issues. Fan Noise means that, engines equipped with cooling fans, particularly at low speeds or when idling, can produce a noticeable whirring or humming sound.

5.2. Electric motor noise

An electric vehicle has no engine. Instead, there is a motor system powered by a battery inside. Unlike thermodynamics, electromagnetics doesn’t result in noise emissions. The motor almost provide no noise, almost silent. Electromagnetic Noise is caused by electric motors generating electromagnetic fields as part of their operation. These fields can interact with nearby components or other electromagnetic devices, resulting in electromagnetic interference (EMI) and audible noise. Shielding and proper grounding techniques can help reduce this type of noise. Mechanical Vibrations is a kind of Vibrations within the motor can cause audible noise. These vibrations may arise due to imbalances in rotating parts, misalignment, loose connections, or worn-out bearings. Proper maintenance, alignment, and balancing can minimize mechanical vibrations and associated noise.

Air flow noise is cooling fans or ventilation systems used in electric motors can generate noise as they move air to dissipate heat. Optimizing fan blade design, using noise-absorbing materials, or employing sound enclosures can mitigate air flow noise. Rotor-Stator Interaction means that interaction between the rotor and stator can lead to acoustic noise. This phenomenon, known as electromagnetic noise or magnetostriction, occurs when rapid changes in magnetic fields cause the motor’s core material to expand and contract, producing audible vibrations. Tyre noise also depends on the speed people drive. The faster people drive, the louder the sound is, more people will hear the noise.

5.3. Spark-ignition engine vibration

Engine Vibration means spark-ignition engines typically generate vibrations during their operation. These vibrations are primarily caused by the reciprocating motion of pistons, connecting rods, and other moving engine components. As the pistons move up and down within the cylinders, spark-ignition engine create forces that result in oscillating vibrations. Additionally, the combustion process itself can cause fluctuations and vibrations in the engine. The magnitude and frequency of vibrations in spark-ignition engines can vary depending on factors such as engine design, balance, and overall smoothness of operation.

5.4. Electric Motor Vibration

Electric motors generally produce fewer vibrations compared to spark-ignition engines. This is because electric motors have a different operating principle without reciprocating motion or internal combustion. While there may be some minor vibrations related to the rotational motion of the motor’s rotor and the magnetic fields generated, these vibrations are typically far less pronounced than those in a spark-ignition engine. Moreover, advancements in motor design and manufacturing techniques have allowed for improved balance and reduced vibration levels in electric motors [9].

6. Results

Overview the whole essay, after comparing the advantage and disadvantages of spark-ignition engine and electric motor, the results are shown as these parts. Electric motors are generally having a higher efficiency than spark-ignition engines. Electric motors can turn most of electrical energy to mechanical energy, whereas spark-ignition engines have significant energy losses due to combustion inefficiencies, heat dissipation, and mechanical friction. Spark-ignition engines typically rely on fossil fuels such as gasoline or diesel, which contribute to greenhouse gas emissions. In contrast, electric motors are powered by electricity, the electricity can be added in the battery. Their environmental impact depends on the source of that electricity. If the electricity is generated from renewable sources, such as wind or solar energy, the overall emissions associated with electric motors can be significantly lower. Electric motor commonly uses electricity as fuel source. And electric motors can be powered by batteries, which store electrical energy chemically. Battery-powered electric motors are commonly found in electric vehicles and portable devices. The motors draw electricity from the battery pack to generate mechanical power.

Electric motors are known for their quiet operation, producing minimal noise and vibration compared to spark-ignition engines. Spark-ignition engines generate noise and vibration due to their mechanical components, combustion processes, and exhaust systems. Electric motors provide a smoother and quieter driving experience.

It is important to notice noise levels can vary based on the design and insulation of vehicles, as well as other factors like tire noise and road conditions. However, in general, electric motors offer a quieter and more refined driving experience. Vibration levels also differ between spark-ignition engines and electric motors. Spark-ignition engines have reciprocating parts and rotating assemblies that can generate noticeable vibrations, while electric motors have fewer moving parts, resulting in reduced vibrations.

7. Conclusion

In the future, electric motor vehicles will get more and more popular, although electric have some weakness points, the merit always higher than weakness. Not only the environmentally friendly, but also the high efficiency, and a lot of advantages of electric motor lead it to the most popular and useful invention and engines or motor in the world. The environment problem cause this change of engines, the earth is getting warmer and warmer, if people still use too many spark-ignition engines, the environment will get worse, so using electric motor is a very good choice for people to help solve the environment problems. And the spark-ignition engine may continue to evolve with improved combustion efficiency, reduced frictional losses, and advanced fuel injection systems. This could lead to higher power output, better fuel economy, and reduced emissions. Also, spark-ignition engines can be integrated into hybrid powertrains, combining them with electric motors and batteries. Additionally, the use of alternative fuels such as biofuels, hydrogen, or synthetic fuels might reduce carbon emissions and reliance on fossil fuels. More and more people will drive electric vehicles. and while spark-ignition engines are expected to undergo improvements in efficiency, hybridization, and digitalization, electric motors will continue to advance with better battery technology, charging infrastructure, and integration into new mobility solutions. The future is likely to involve a combination of both technologies as people strive for a more sustainable and efficient transportation ecosystem [10].

References

[1]. Teddy A 2020 Experimental Thermal and Fluid Science 119(2):110176 DOI:10.1016/j.expthermflusci.2020.110176

[2]. Benny C 2022 History of the internal combustion engine

[3]. Alpesh K. Panchal Chirag M. Patel Gaurav P. Rathod Tushar M. Patel 2014 Performance and Exhaust Gas Emission of Compressed Natural Gas Fueled Internal Combustion Engine in Dual Fuel Mode IJRTS Vol.1

[4]. ALD February 2022 Automotive Fuhrparkmanagement und Leasing GmbH

[5]. MIDC, Kupwad, Sangli India Engine theory and calculations 416436 (MS)

[6]. P.Naresh1*, A.V.Hari Babu 2015 Concept of Six Stroke Engine J. of Advancement in Engineering and Technology V314.

[7]. Hasan T. Hashim and Murtdha S. Imran 2018 Electrical Current Generation Using SI Engine Waste Exhaust Heat in a Thermoelectric Generator . 433 012065

[8]. ChangChun Xu1 HaengMuk Cho 2018 Analysis on the Noise Reduction of Engine with Air Intake Resonator in Engine Intake System ijet v10i1

[9]. Berlin, Germany, 25. - 27. February 2013 SIM 2013 - 10th International Conference on Vibrations in Rotating Machines,

[10]. Charles K. 2022 2022 Hybrid electric vehicle specific engines: State-of-the-art ...

Cite this article

Pan,H. (2024). Traditional engines spark-ignition engine versus alternatives electric motor. Theoretical and Natural Science,31,126-132.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Computing Innovation and Applied Physics

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Teddy A 2020 Experimental Thermal and Fluid Science 119(2):110176 DOI:10.1016/j.expthermflusci.2020.110176

[2]. Benny C 2022 History of the internal combustion engine

[3]. Alpesh K. Panchal Chirag M. Patel Gaurav P. Rathod Tushar M. Patel 2014 Performance and Exhaust Gas Emission of Compressed Natural Gas Fueled Internal Combustion Engine in Dual Fuel Mode IJRTS Vol.1

[4]. ALD February 2022 Automotive Fuhrparkmanagement und Leasing GmbH

[5]. MIDC, Kupwad, Sangli India Engine theory and calculations 416436 (MS)

[6]. P.Naresh1*, A.V.Hari Babu 2015 Concept of Six Stroke Engine J. of Advancement in Engineering and Technology V314.

[7]. Hasan T. Hashim and Murtdha S. Imran 2018 Electrical Current Generation Using SI Engine Waste Exhaust Heat in a Thermoelectric Generator . 433 012065

[8]. ChangChun Xu1 HaengMuk Cho 2018 Analysis on the Noise Reduction of Engine with Air Intake Resonator in Engine Intake System ijet v10i1

[9]. Berlin, Germany, 25. - 27. February 2013 SIM 2013 - 10th International Conference on Vibrations in Rotating Machines,

[10]. Charles K. 2022 2022 Hybrid electric vehicle specific engines: State-of-the-art ...