1. Introduction

Thermal barrier coating (TBC) technology, as an effective anti-high temperature protection measure, is widely used in gas turbines, aircraft engines and other equipment that need to work in high temperature environment for a long time. By applying one or more layers of special coatings on the surface of high-temperature components of the equipment, the TBC system can effectively isolate the high temperature and reduce the transfer of heat to the substrate, thereby improving the operation efficiency of the equipment and extending the service life. With the development of industrial technology, the demand for equipment such as gas turbines is increasing. How to design a more efficient and reliable TBC system has become a key issue to be solved urgently. The performance of TBC system is affected by many factors, among which material selection is the basic and key link. The TBC system usually consists of a bonding layer and a ceramic surface layer. The adhesive layer is mostly made of Ni-based superalloy, which is widely used because of its excellent high temperature mechanical properties and thermal expansion coefficient matching with ceramic coating [1]. The ceramic surface is mainly composed of zirconia (ZrO2) stabilized phase, and its thermal stability is improved by adding stabilizers such as Y2O3 or La2O3. EB-PVD and APS are two widely used coating technologies, each of which has its own characteristics, and the most suitable coating process can be selected according to different application requirements. The stability and life of TBC system under extreme service conditions is another important research content. Thermal stress is one of the key factors affecting the performance and life of TBC, so it is of great significance to analyze and optimize the thermal stress of TBC system by finite element analysis (FEA) and other mathematical models to improve the performance and stability of TBC system. In addition, it also has important theoretical and practical significance for the life prediction and failure mechanism analysis of TBC system and can provide guidance for the subsequent design and improvement of TBC system.

In summary, this study aims to analyze material selection, coating scheme, thermal stress analysis and optimization strategy, life prediction and failure mechanism of TBC system, and propose a series of optimization design and performance improvement strategies to meet the high performance requirements of gas turbines and other high-temperature equipment for TBC system.

2. Material selection and performance evaluation

2.1. TBCs material composition

The performance of the thermal barrier coating (TBC) system greatly depends on the composition of the material. The binding layer is generally made of nickel based high temperature alloy, and is widely used for its excellent high temperature desk performance and a number of good thermal expansion systems consistent with ceramic courts. In addition, nickel based high temperature alloys can form dense chromium oxide protective layers at high temperatures to effectively prevent oxidation and corrosion [2]. However, it is important to select the appropriate alloy components to ensure the optimum bonding. For example, alloys of the appropriate ratio of aluminum and chromium can form more stable protective oxides at high temperatures and extend the life of the TBC system.

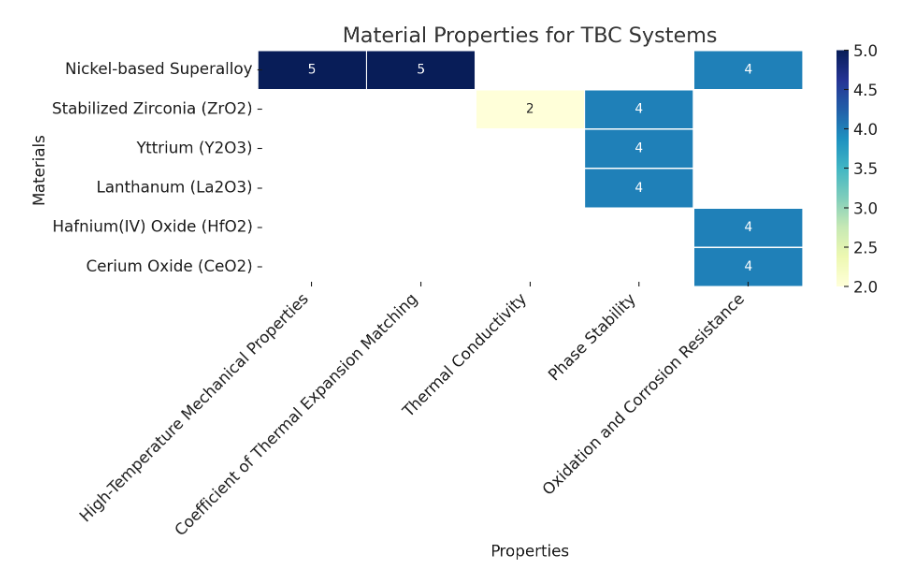

Figure 1. Comparative Chart of Material Properties for Thermal Barrier Coating (TBC) Systems

The surface of the ceramic is stabilized by zirconia (ZrO 2), and the thermal stability is en-hanced by adding stabilizer such as yttrium (Y 2O 3) and lanthanum (La 2O 3). Zirconia sta-bilizers can maintain low thermal conductivity and good phase stability at high temperatures, and are effective to effectively cut off high temperatures and reduce heat transfer to underly-ing materials. In recent years, it has been studied to enhance the performance of ceramic sur-faces by adding hafnium tetra (HfO2) and cerium (CeO2) as a new stabilizer. Figure 1 shows the performance of different materials used in thermal barrier coating (TBC) systems.

2.2. Effects of coating methods

Electron beam physical vapor deposition (EB PVD) and plasma ink-jet (APS) are superior to the generation of TBC. EB PVD technology can produce ceramic coatings with columnar crystalline structure, which increases the resistance to thermal stress in the thermal cycling process of the coating layer and reduces cracking and diffusion. The EB PVD coating has the capability of “self healing” because of its unique microstructure. That is, after cracking occurs, the microstructure can be adjusted to “close” the crack and extend the life of the coating. However, the high cost of EB PVD technology limits extensive use in some applications [3].

APS technology is less expensive than EB PVD and is suitable for wide area coating. APS technology melts ceramic material in high temperature plasma and injects it into base to form layer structure. Although the APS coating is less resistant to heat resistance than columnar coating made by EB PVD, it is possible to improve the densification and bonding strength of the coating remarkably by optimizing the ink jet parameter and the heat treatment technology such as heat treatment, and the performance can be improved.

2.3. Effects of environmental factors on tbcs performance

In practice, the TBCs system must maintain its stability and lifetime under bad working conditions. For example, high temperature environments may not only increase temperature stress but also cause high temperature oxidation and thermal corrosion. In this environment, the phase change of the ceramic layer and oxidation of the bonding layer may affect the overall performance of the TBC. Therefore, in the design of the TBC system, it is necessary to consider the stability in the high temperature oxidation corrosion environment in addition to the high temperature performance of the material [4]. By adding antioxidant and anti-corrosion elements (aluminum, chromium, silicon, etc.) to the binding layer, the environmental stability of the TBC system can be enhanced as shown in Table 1. In addition, it is possible to improve the stability and long life of the ceramic surface by adding an anti oxidation phase.

Table 1. Improvements in Thermal Barrier Coating (TBC) Systems Performance through Anti-Oxidation and Anti-Corrosion Enhancements

Factor | Performance Metric Without Enhancement | Performance Metric With Enhancement | Enhancement Details | High Temperature | 70% | 90% | Improved high-temperature performance of materials | Thermal Stress | 60% | 85% | Enhanced thermal shock resistance | High Temperature Oxidation | 50% | 88% | Addition of Al, Cr, Si for anti-oxidation | Hot Corrosion | 55% | 92% | Addition of Al, Cr, Si for anti-corrosion | Phase Transformation Stability | 65% | 95% | Enhanced ceramic coating stability | Bonding Layer Oxidation | 58% | 90% | Improved bonding layer with anti-oxidation elements | Overall Environmental Stability | 59% | 93% | Comprehensive enhancement with anti-oxidation phases |

3. Thermal stress analysis and optimization

3.1. Thermal stress model of TBCs

The thermal barrier coating (TBC) system is an important factor in the thermal performance due to the difference between the thermal performance of the working environment and the number of thermal expansions between different materials. To understand and predict the distribution of thermal stresses in the TBC system, a mathematical model based on finite element analysis (FEA) is generally created. These models can simulate the behavior of the TBC system under complex thermal loading, including the temperature field distribution, the generation of thermal stress, and the integrity of the coat. Specifically, this mathematical model generally considers the multi-layer structure of the coating layer, the physical properties of each layer (thermal expansion coefficient, thermal conductivity and modulus of elasticity), and the thermal contact impedance between the interfaces. By using this model, it is possible to simulate the fluctuation of the thermal stress by the rapid temperature change at the time of stopping / stopping. It can also be used to evaluate the effects of different coating thicknesses, material selection and structural design on the thermal stress distribution, providing theoretical rationale for the optimal design of the TBC system. Using this method, we found that thermal stress concentrates on the interface between the coat layer and the substrate, especially in the edge and fragmentation area of the coat layer [5]. Therefore, it is possible to teach the design of the TBC system by prediction and analysis of the thermal stress distribution by the mathematical model. For example, optimizing the combination of coating thickness and material can reduce the thermal stress concentration and the risk of coating burdens and improve the stability and lifetime of the TBC system.

3.2. Effect of material properties on thermal stress

The number of thermal expansion systems, the thermal conductivity and the modulus of elasticity are important factors determining the thermal stress distribution, and the performance and life span of the thermal barrier coating system are significantly affected by the chemical properties of the constituent materials. For example, the consistency of the thermal expansion coefficient between the adhesive layer and the upper ceramic coating layer directly affects the thermal stress level at the interface. Ideally, by selecting a material with a near thermal expansion coefficient, the internal stress due to the temperature gradient can be minimized and the crack formation and diffusion can be reduced.

In addition, the upper layer ceramic coat has low thermal conductivity and can cut the high temperature, but the temperature gradient inside the coat increases, and the thermal stress increases [6]. Thus, the key to improving the performance of the TBC system is to optimize the chemical composition and microstructure of ceramic coatings and to balance the adiabatic and thermal stresses.

The difference of elastic modulus also affects the thermal stress distribution. At high temperatures, the elastic modulus of the material generally decreases and affects the mechanical stability of the material in the thermal cycle [7]. By selecting materials with a stable modulus under high temperatures, the stability and durability of the TBC system can be enhanced under extreme operating conditions.

4. Life Prediction and failure mechanism analysis of TBCs

4.1. Life prediction model

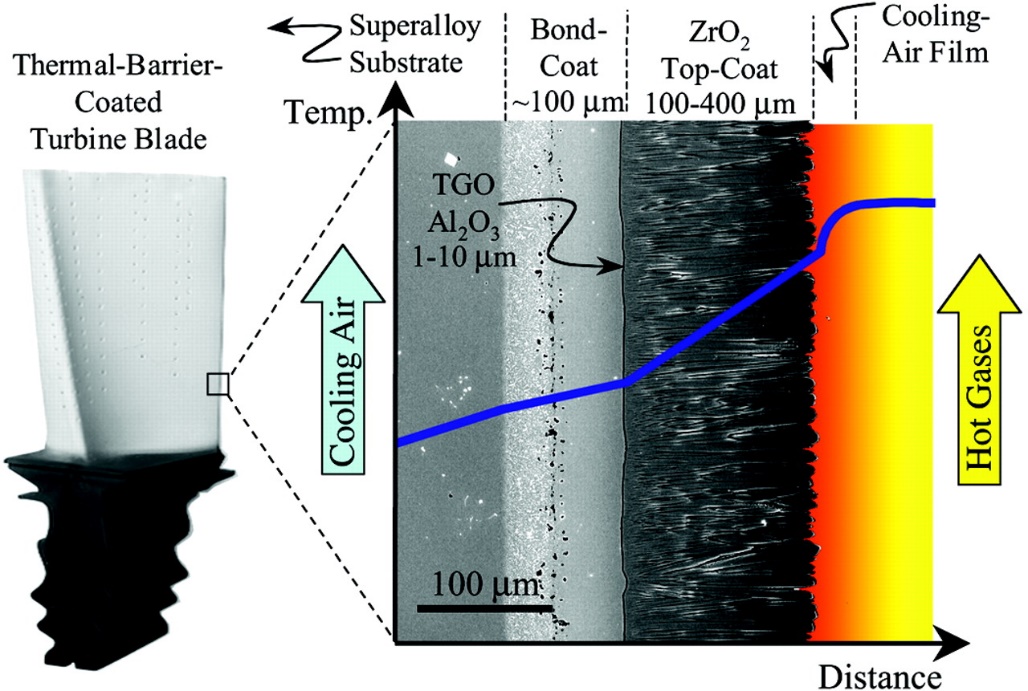

A mathematical model based on physical and chemical mechanisms is needed to predict the lifetime of thermal barrier coating (TBC) systems, as shown in Figure 2. These models considered the growth rate of thermally grown oxide layer (TGO), the stress state of the coating interface and the effect of external working environment on the coating layer performance. For example, the growth dynamics of the TGO layer can be described using the Arrhenius equation, and the stress con-centration at the interface can be predicted by combining the stress analysis model such as the finite element model FEM, and the detachment time of the coating layer can be evaluat-ed. These models also introduced the circulation factor to simulate the effect of thermal cy-cling on the stability of the TBC structure and to simulate the effect of thermal shock under actual operating conditions [8]. By comparing with experimental data, these models can ac-curately predict the actual usage life of the TBC system and provide powerful theoretical support for a more reliable TBC system design.

Figure 2. Thermal Barrier Coatings for Gas-Turbine Engine Applications (Source: science.org)

4.2. Precautions and performance improvements

Understanding the mechanism of deactivation has led researchers to propose a series of strategic precautions and performance improvements for Thermal Barrier Coatings (TBCs). One such strategy involves the integration of rare earth elements, such as yttrium (Y), into the high-temperature layer of the ceramic. This addition aims to bolster the thermal stability and antioxidant capabilities of the Thermally Grown Oxide (TGO) layer. By doing so, the progression of the TGO layer’s growth can be effectively delayed, thereby enhancing the overall durability of the coating under extreme conditions. Furthermore, advancements have been made in the composition of the bonding layer’s alloy. By optimizing this alloy, researchers can better match the thermal expansion properties of the bonding layer with those of the TGO layer. This alignment significantly reduces stress concentrations at the interface between these layers, which are critical points that could otherwise lead to premature failure. In terms of application techniques, the adoption of laser welding in the coating process has proven to be highly beneficial. This technique facilitates the formation of a denser and more uniform transient layer between the coating and the base material. Not only does this increase the bonding strength of the coating, but it also enhances the heat resistance of the overall TBC system. Such improvements in the application process ensure a more robust integration of the coating, further improving the system’s resistance to thermal shock and prolonging its functional life [9].

By implementing these innovative approaches, the operational lifespan of TBC systems can be significantly extended. These enhancements are crucial for maintaining the reliability and efficiency of gas turbines, especially under the rigorous conditions of high temperature and pressure that are typical in such environments. As a result, these strategic improvements not only preserve the integrity of the TBC system but also contribute to the overall operational sustainability of gas turbines.

5. Conclusion

This paper has comprehensively addressed the performance design and optimization of Thermal Barrier Coating (TBC) systems, crucial for enhancing the efficiency and longevity of high-temperature equipment such as gas turbines. Through an in-depth examination of various aspects of TBC systems—including material selection, application techniques, and thermal stress management—this study has identified and implemented strategies to augment the performance of these protective coatings. Our research began with a meticulous analysis of material selection for the TBC system. By choosing materials with optimal thermal properties and compatibility, we significantly enhanced the adiabatic effectiveness of the TBC, thereby reducing the thermal load on the underlying components. The careful selection of materials not only improves the system’s stability but also its ability to withstand extreme operational conditions. Further, the study delved into the coating processes, employing advanced techniques such as laser welding to ensure a stronger, more resilient bonding between the coating layers and the base materials. These refined application methods contribute to a more uniform coat distribution, minimizing the risk of thermal stress concentrations that could lead to coating failure. A pivotal aspect of our research involved the development and utilization of sophisticated mathematical models to predict and analyze thermal stresses within the TBC system. These models provide a robust framework for simulating various operational scenarios and assessing the TBC’s response to thermal loads. The insights gained from these analyses offer powerful theoretical support for the optimal design of TBC systems, ensuring they are tailored to withstand specific operational demands. Additionally, we established a life prediction model for TBC systems that incorporates analyses of the mechanisms behind coating deactivation and degradation. Understanding the structural changes that occur at the microscopic level under severe environmental conditions allows us to better predict the system’s lifespan and identify potential failure points. This predictive capability is instrumental in designing TBC systems that are not only more reliable but also have longer service lives. The culmination of this research provides valuable theoretical insights and practical guidelines for the design and enhancement of TBC systems. It has significant implications for the development of more robust, efficient, and durable coatings, essential for the operational success of gas turbines and other high-temperature applications. The strategies proposed in this study offer a pathway to significantly improve the reliability and performance of TBC systems, ensuring they meet the evolving demands of modern industrial applications.

References

[1]. Iqbal, Amjad, and Grzegorz Moskal. “Recent development in advance ceramic materials and under-standing the mechanisms of thermal barrier coatings degradation.” Archives of Computational Meth-ods in Engineering 30.8 (2023): 4855-4896

[2]. Barwinska, Izabela, et al. “Thermal Barrier Coatings for High-Temperature Performance of Nickel-Based Superalloys: A Synthetic Review.” Coatings 13.4 (2023): 769.

[3]. Rahimi, Javad, Mohammad Rasoul Javadi Sigaroodi, and Esmaeil Poursaeidi. “Thermal shock re-sistance of thermal barrier coating with different bondcoat types and diffusion pre-coating.” Ceramics International 49.2 (2023): 2061-2072.

[4]. Krishnamoorthi, Thiruselvam, et al. “Influence of thermal barrier coating on performance and emission characteristics of a compression ignition engine fueled with delonix regia seed biodiesel.” Journal of Cleaner Production 420 (2023): 138413.

[5]. Chowdhury, Taspia Shawkat, et al. “A critical review on gas turbine cooling performance and failure analysis of turbine blades.” International Journal of Thermofluids 18 (2023): 100329.

[6]. Banihabib, Reyhaneh, et al. “Development and testing of a 100 kW fuel-flexible micro gas turbine running on 100% hydrogen.” International Journal of Hydrogen Energy 49 (2024): 92-111.

[7]. Kangishwar, S., et al. “A comprehensive review on polymer matrix composites: material selection, fabrication, and application.” Polymer Bulletin 80.1 (2023): 47-87.

[8]. Oladokun, Olanrewaju, and Kong Fah Tee. “Material Selection and Structural Assessment of Offshore Aquaculture Floating Structures for Seaweed Farming.” (2023).

[9]. Nabiyev, M., and A. Abobakirov. “ENERGY-EFFICIENT MATERIALS IN BUILDINGS AND STRUCTURES: TECHNOLOGIES AND TRENDS.” Innovative Development in Educational Activities 2.23 (2023): 43-48.

Cite this article

Lang,Z.;Makunza,J. (2024). Optimization design and performance improvement of ther-mal barrier coating (TBC) system. Theoretical and Natural Science,39,180-185.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Mathematical Physics and Computational Simulation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Iqbal, Amjad, and Grzegorz Moskal. “Recent development in advance ceramic materials and under-standing the mechanisms of thermal barrier coatings degradation.” Archives of Computational Meth-ods in Engineering 30.8 (2023): 4855-4896

[2]. Barwinska, Izabela, et al. “Thermal Barrier Coatings for High-Temperature Performance of Nickel-Based Superalloys: A Synthetic Review.” Coatings 13.4 (2023): 769.

[3]. Rahimi, Javad, Mohammad Rasoul Javadi Sigaroodi, and Esmaeil Poursaeidi. “Thermal shock re-sistance of thermal barrier coating with different bondcoat types and diffusion pre-coating.” Ceramics International 49.2 (2023): 2061-2072.

[4]. Krishnamoorthi, Thiruselvam, et al. “Influence of thermal barrier coating on performance and emission characteristics of a compression ignition engine fueled with delonix regia seed biodiesel.” Journal of Cleaner Production 420 (2023): 138413.

[5]. Chowdhury, Taspia Shawkat, et al. “A critical review on gas turbine cooling performance and failure analysis of turbine blades.” International Journal of Thermofluids 18 (2023): 100329.

[6]. Banihabib, Reyhaneh, et al. “Development and testing of a 100 kW fuel-flexible micro gas turbine running on 100% hydrogen.” International Journal of Hydrogen Energy 49 (2024): 92-111.

[7]. Kangishwar, S., et al. “A comprehensive review on polymer matrix composites: material selection, fabrication, and application.” Polymer Bulletin 80.1 (2023): 47-87.

[8]. Oladokun, Olanrewaju, and Kong Fah Tee. “Material Selection and Structural Assessment of Offshore Aquaculture Floating Structures for Seaweed Farming.” (2023).

[9]. Nabiyev, M., and A. Abobakirov. “ENERGY-EFFICIENT MATERIALS IN BUILDINGS AND STRUCTURES: TECHNOLOGIES AND TRENDS.” Innovative Development in Educational Activities 2.23 (2023): 43-48.