1. Introduction

Expansion chamber muffler is one of the primary forms of resistance muffler, widely used in life, industry, automobile, aviation, and other fields [1-3]. In particular, it has played an essential role in reducing the noise generated by mechanical equipment, automobile engines, aircraft turbines, and so on.

With the increasing attention to environmental noise pollution and the promotion of industrialization, the scale of the muffler market has shown a trend of continuous growth in the past few years. It is expected that in the next few years, with the stricter environmental laws and regulations and the constant progress of technology, the demand for multi-section expansion chamber mufflers will further increase, and the market prospect is broad.

Therefore, because of the universality and versatility of the multi-section expansion chamber muffler, it is of great significance to study the influence of its structural parameters on its noise suppression performance. At present, many literatures have discussed the effects of several different structural parameters on the noise suppression performance of mufflers. Shi Jianfeng applied the finite element analysis method [4]. Through the simulation comparison analysis of expansion cavity series with different expansion ratio and expansion cavity with different cavity length, the effects of expansion ratio and expansion chamber length on the transmission loss of muffler expansion chamber in series are summarized. Han Lei et al. used the method of connecting two mufflers in series to simulate and analyze the effects of the length of the connecting tube[5], the diameter of the connecting tube, the length ratio of the front and rear expansion chamber, and the diameter ratio of the expansion chamber on the transmission loss of the muffler. Chen Guoping et al. made a simulation calculation of the transmission loss of the series muffler [6]. The effects of the length of the middle connecting tube, the diameter of the middle connecting tube, the length of the expansion cavity and the diameter of the expansion cavity on the transmission loss of the double expansion cavity series muffler are studied systematically. There are also studies dedicated to the analysis of certain structural parameters, such as the effects of expansion ratio, position and number of outlet tubes on the noise suppression performance of expansion mufflers [7,8], and the specific application of mufflers to diesel engine exhaust applications. The effects of more complex structural parameters such as the offset distance of the insertion tube and different shapes of the expansion cavity on the noise suppression performance are discussed [9].

This paper uses Actran software to analyze and discuss the influence of different parameters on the muffler performance by changing the structural parameters such as the number of muffler expansion chamber, the diameter of cross-section of front and rear expansion chamber, the length of front and rear expansion chamber, the length of connecting tube, the arrangement order of expansion chamber with different cross-sectional area and the arrangement order of expansion chamber with different length. Through this study, the results can be used as a reference for the design of multi-section expansion chamber muffler, and it is of great significance for the development of a new type of muffler.

2. Principle and structure design of multi-section expansion chamber muffler

2.1. Principle of muffler with multi-section expansion chamber

When the sound wave passes through the muffler, the sudden expansion or contraction of the cross-section of the pipe causes the sound wave to reflect and interfere at these changes [10]. This reflection and interference can disperse the energy of sound waves, thus reducing the intensity of noise. At the same time, the design of the expansion chamber changes the acoustic impedance in the pipe [11]. This change can affect the propagation of sound waves, so that the energy of high-frequency and fast-frequency sound waves decreases gradually when they pass through the muffler. And in the process of sound wave propagation, due to reflection, interference and damping, the energy of sound wave is dissipated, thus reducing the intensity of noise.

2.2. Structural design of multi-section expansion chamber muffler

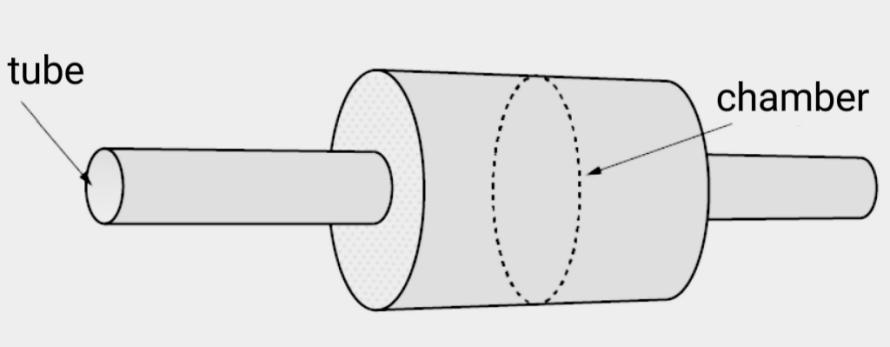

Multi-section expansion chamber muffler is mainly composed of two basic parts: tube and chamber. Among them, the chamber is the expansion chamber, and its function is to provide space for sound wave reflection and interference [12].

Compared with the single-section expansion muffler, the multi-section expansion chamber muffler has multiple expansion chambers. This design can disperse the energy of sound waves more effectively and improve the anechoic effect. At the same time, the muffler has an inlet pipe and an outlet pipe, which are used to guide the gas flow through the muffler. The sound wave enters the expansion chamber through the inlet pipe and is discharged through the outlet pipe after reflection, interference and energy dissipation. In some multi-section expansion chamber mufflers, reflector plates are also used to further promote the reflection and interference of sound waves. The design of the reflector can be adjusted according to the specific needs to achieve the best noise suppression effect. Figure 1 and figure 2 are the structure diagrams of single-section expansion chamber muffler and multi-section expansion chamber muffler respectively.

|

|

Figure 1. Structure of single expansion chamber muffler | Figure 2. Structure of multi-section expansion chamber muffler |

3. Transmission loss of muffler

The transmission loss formula of multi-section expansion chamber silencer is usually derived based on the transmission loss formula of single expansion chamber silencer. In the case of a single expansion chamber silencer, the transmission loss is related to the expansion ratio and the expansion chamber length [13]. For the multi-section expansion chamber muffler, the transmission loss can be regarded as the superposition of the transmission loss of each single section muffler.

A common transmission loss formula for a single expansion muffler can be expressed as follows:

\( {L_{TL}}=10lg{( 1+\frac{1}{4{(m-\frac{1}{m})^{2}}}{sin^{2}}{k}L)}\ \ \ (1) \) Where:

\( {L_{TL}} \) -- Transmission loss (unit: dB)

m--expansion ratio, defined as( \( m={S_{2}}/{S_{1}} \) ), where \( {S_{1}} \) is the cross-sectional area of the muffler inlet and \( {S_{2}} \) is the cross-sectional area of the muffler expansion chamber

k is the wave number, which is related to the sound frequency f and the speed of sound c

L is the length of the expansion chamber

For the multi-section expansion chamber silencer, the transmission loss is the superposition of the transmission loss of each single section muffler. Suppose there is a n-section expansion chamber, and the transmission loss of each section is \( {L_{TL,1}} \) ,,..., \( {L_{TL,n}} \) , then the total transmission loss T of many expansion chamber silencers \( {L_{TL,total}} \) can be expressed as:

\( {L_{TL,total}}=\sum _{i=1}^{n}{L_{TL,i}}\ \ \ (2) \)

Among them, each \( {L_{TL,i}} \) can be calculated by using the transmission loss formula of the single expansion chamber silencer.

The transmission loss of multi-section expansion chamber silencer is the superposition of the transmission loss of each single section muffler. This means that the overall silencing effect can be further improved by increasing the number of sections of the silencer, and this conclusion can be drawn intuitively according to the above formula. Similarly, through this formula, it can also be seen that the transmission loss increases with the increase of the expansion ratio m (the default \( {S_{2}} \) is greater than \( {S_{1}} \) , so m is greater than 1), and the transmission loss changes periodically with the increase of the expansion chamber length L. however, in the range of common expansion chamber length, the transmission loss increases with the increase of expansion chamber length L.

It should be noted that this formula is a simplified expression, and in practice, the transmission loss of multi-section expansion chamber silencers may also be affected by other factors, such as coupling effect between segments, air flow velocity, temperature and so on. It can be seen from the formula that the transmission loss of the muffler can be changed by changing the parameters such as the expansion ratio of the muffler and the length of the expansion chamber. This paper will take the multi-section cylindrical expansion chamber muffler as the research object.

4. Emulation analysis

4.1. Analysis proc

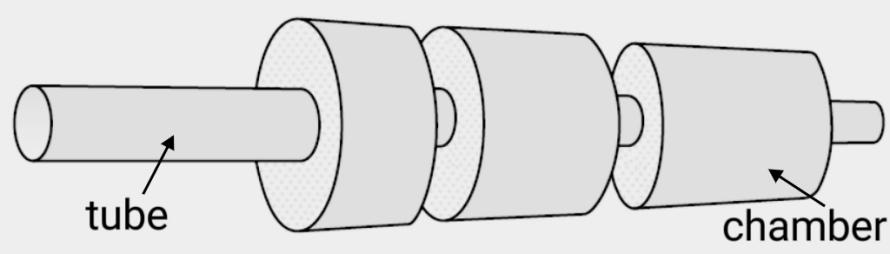

The specific process of this lab is shown in figure 3. Firstly, the muffler model is modeled by SpaceClaim software, and then the internal air volume model of the muffler is obtained by its volume extraction function. After it is imported into Actran software, the simulation pre-processing is carried out, including defining the entrance and exit, setting fluid properties and sound source excitation, etc., and finally the structure is obtained by simulation.

|

Figure 3. Simulation analysis flow chart |

4.2. Silencer model parameter setting

This paper sets the model of muffler outlet, inlet diameter 10mm, expansion chamber node number 2, cross-section diameter and length of each expansion chamber 30mm and 40mm, and connecting pipe length 30mm as the reference model, as shown in table 1 and figure 4.

Table 1. Reference model data

Entrance diameter(mm) | Outlet diameter (mm) | Number of expansion chamber nodes | cross-section diameter of expansion chamber(mm) | Expansion chamber length (mm) | Length of connecting pipe (mm) |

10 | 10 | 2 | 30 | 40 | 30 |

Figure 4. Reference model

At the same time, this paper follows the principle of single factor. The number of muffler expansion chamber A, the cross-section diameter B of the previous expansion chamber, the cross-section diameter C of the latter expansion chamber, the length D of the previous expansion chamber, the length E of the latter expansion chamber, the length of the connecting tube F and the expansion chamber arrangement order with different cross-sectional area and different length are compared with the reference model (set the reference model simulation as experiment group 1) as variables. In order to obtain the influence of different parameters on the noise suppression performance of multi-section expansion muffler. The changes of specific structural parameters and their corresponding groups are shown in table 2 and 3.

Table 2. The corresponding groups of experiments with different structural parameters

Parameter | Number of nodes in muffler expansion chamber | Cross-sectional diameter of front and rear expansion chamber | Length of front and rear expansion chamber | Length of connecting pipe | The order of expansion chambers with different cross-sectional areas | The order of expansion chambers with different lengths |

Experimental group | ①②③ | ①④⑤ | ①⑥⑦ | ①⑧⑨ | ①⑩⑪ | ①⑫⑬ |

Table 3. Simulation analysis compared with parameter setting

A | B | C | D | E | F | |

① | 2 | 30 | 30 | 40 | 40 | 30 |

② | 3 | 30 | 30 | 40 | 40 | 30 |

③ | 4 | 30 | 30 | 40 | 40 | 30 |

④ | 2 | 40 | 40 | 40 | 40 | 30 |

⑤ | 2 | 50 | 50 | 40 | 40 | 30 |

⑥ | 2 | 30 | 30 | 50 | 50 | 30 |

⑦ | 2 | 30 | 30 | 60 | 60 | 30 |

⑧ | 2 | 30 | 30 | 40 | 40 | 40 |

⑨ | 2 | 30 | 30 | 40 | 40 | 50 |

⑩ | 2 | 45 | 30 | 40 | 40 | 30 |

⑪ | 2 | 30 | 45 | 40 | 40 | 30 |

⑫ | 2 | 30 | 30 | 55 | 40 | 30 |

⑬ | 2 | 30 | 30 | 40 | 55 | 30 |

5. Analysis of simulation results

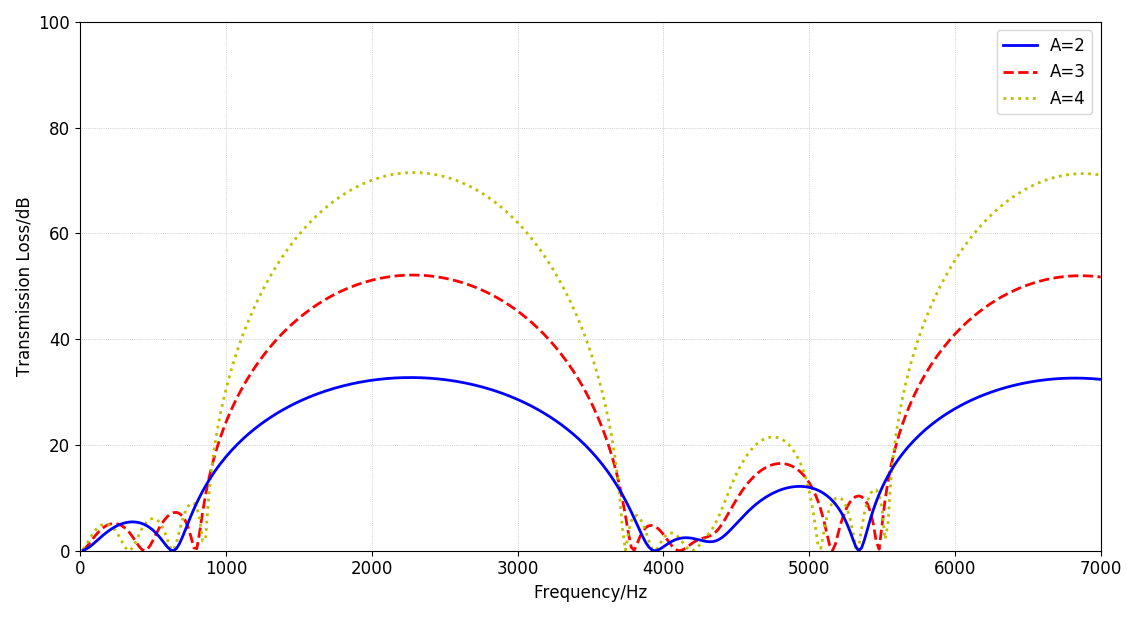

5.1. Effect of the number of expansion chamber nodes on the noise suppression performance

By changing the expansion chamber node number A, ①②③ groups of simulation experiments are compared, the expansion chamber node number is 2, 3, 4 respectively, at the same time, keep the expansion chamber cross-sectional area and expansion chamber length and other variables consistent.

|

Figure 5. Effect of the number of expansion chamber nodes on the noise suppression performance |

As can be seen from figure 5, with the increase of the number of expansion chamber nodes A, the peak value of sound transmission loss increases, and at the same time, the points with transmission loss of 0 also increase. That is to say, the frequency of anechoic effect and the number of passing frequencies increase with the increase of the number of expansion chamber nodes A. Therefore, if the installation space of the silencer is limited, the anechoic energy can be improved by increasing the number of expansion rooms.

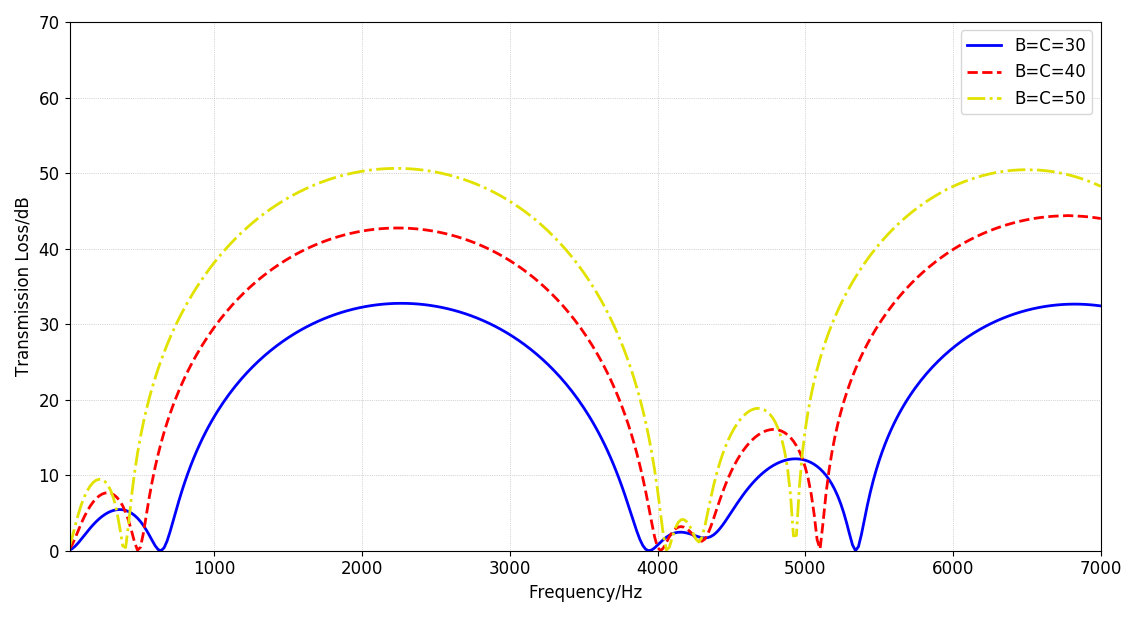

5.2. Effect of cross-section diameter of expansion chamber on anechoic performance

Because this simulation only discusses the influence of the cross-section diameter of the expansion chamber on the anechoic performance, in order that other factors do not affect the simulation results, the cross-section diameters of the two expansion chambers are kept in the same range. In this simulation, three groups of simulation experiments will be set up, and the cross-section diameter of the expansion chamber is 30mm, 40mm, 50mm, respectively. The experimental results are compared to get the effect of the cross-section diameter of the expansion chamber on the noise suppression performance, as shown in figure 6.

It can be seen from the figure that the change of the curve of the multi-expansion chamber silencer with different cross-section diameter is basically the same with the increase of the cross-section diameter of the expansion chamber, the anechoic frequency and the number of passing frequencies remain unchanged, but the peak value of sound transmission loss is different, and the anechoic frequency moves slightly to low-frequency. In fact, the change of the cross-section diameter of the expansion chamber will only change the expansion ratio of the muffler, but not the span of the curve. The larger the diameter of the cross-section of the expansion chamber is, the greater the sound attenuation of the multi-section expansion chamber silencer is, and the better the noise suppression performance is.

|

Figure 6. Effect of cross-section diameter of expansion chamber on anechoic performance |

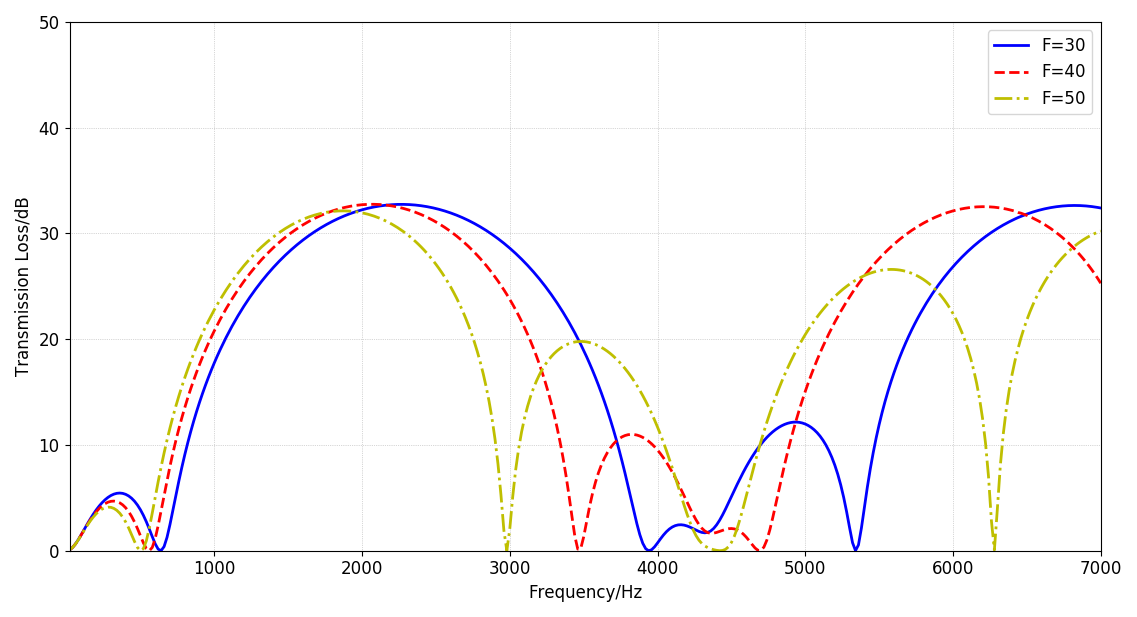

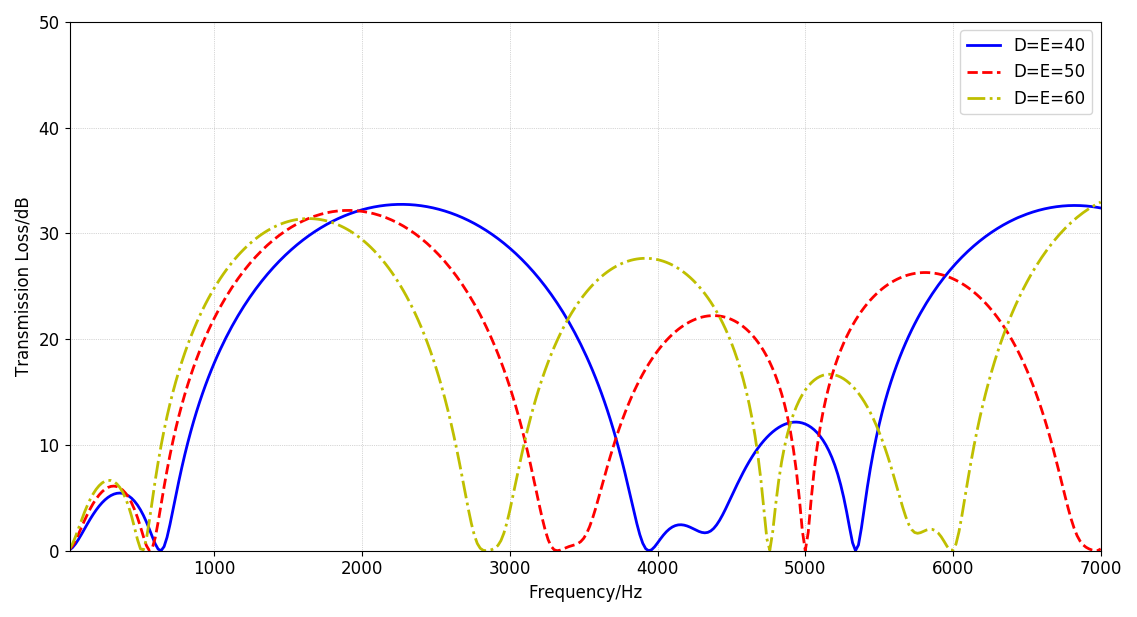

5.3. Effect of expansion chamber length on noise suppression performance

In this experiment, while keeping other parameters consistent, the length of the expansion chamber was set to 40mm, 50mm and 60mm, and the model was imported into Actran. The results are shown in figure 7.

Compared with the results, the peak value of the transfer loss is basically not affected by the change of the expansion chamber length, so increasing the expansion chamber length cannot effectively increase the transfer loss. However, with the increase of the length of the expansion chamber, the curve span of transfer loss decreases and the point where the transfer loss is 0 increases.

Figure 7. Effect of expansion chamber length on noise suppression performance

5.4. Effect of connecting pipe length on muffling performance

Compared with the simulation experimental group ①⑧⑨, the length of the connecting tube of the muffler model was set to 30mm, 40mm and 50mm respectively, and other parameters were controlled to be consistent, and the results were as shown in the figure.

It can be seen from figure 8 that with the increase of the length of the connecting tube, the peak value of the transmission loss of the muffler in the relatively low-frequency range is basically unchanged, but the curve as a whole tends to move slightly to the low-frequency; and when the frequency increases, the point where the transmission loss of the muffler is zero also gradually moves to the low-frequency direction, the curve span decreases, the number of zeros increases, at the same time, the peak value of the transmission loss curve moves to the low-frequency direction, and the number of curve peaks increases.

|

Figure 8. Effect of connecting pipe length on muffling performance |

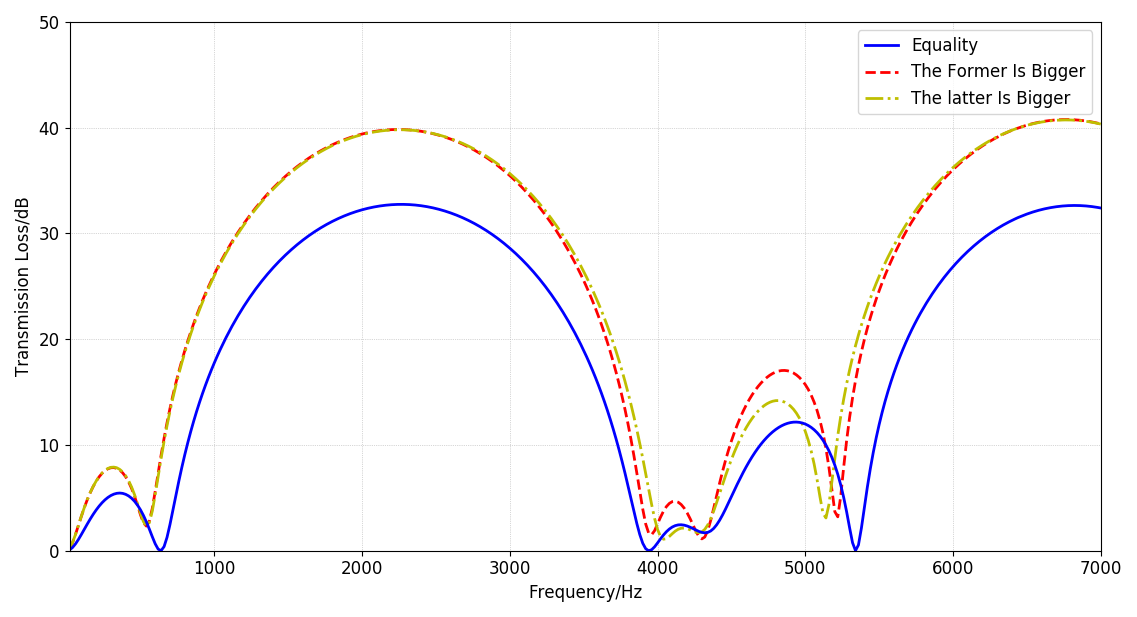

5.5. The influence of the arrangement order of expansion chambers with different cross-section diameters on the silencing performance

In this experiment of the expansion chamber, in order to obtain the influence of the arrangement order of the expansion chamber with different diameters on the muffling performance, the front and rear positions of the cross-section with different straight diameters will be changed and the experiment will be carried out with the same other parameters. Among them, the larger cross-sectional diameter of the expansion chamber is 45mm, the smaller diameter is 30mm, and the two equal expansion chamber diameters are 30mm, which is regarded as the imitation test group of ①⑩⑪. The result is shown in figure 9.

Compared with the simulation results, no matter which expansion chamber before and after increasing the cross-sectional area, it can significantly improve the peak value of the anechoic curve and effectively enhance the anechoic performance. However, comparing the two groups of curves with different arrangement order of different diameter expansion chamber, it is found that the two curves basically coincide. It can be known that the arrangement order of different diameter expansion chamber has no effect on the noise suppression performance of the muffler.

|

Figure 9. The influence of the arrangement order of expansion chambers with different cross-section diameters on the silencing performance |

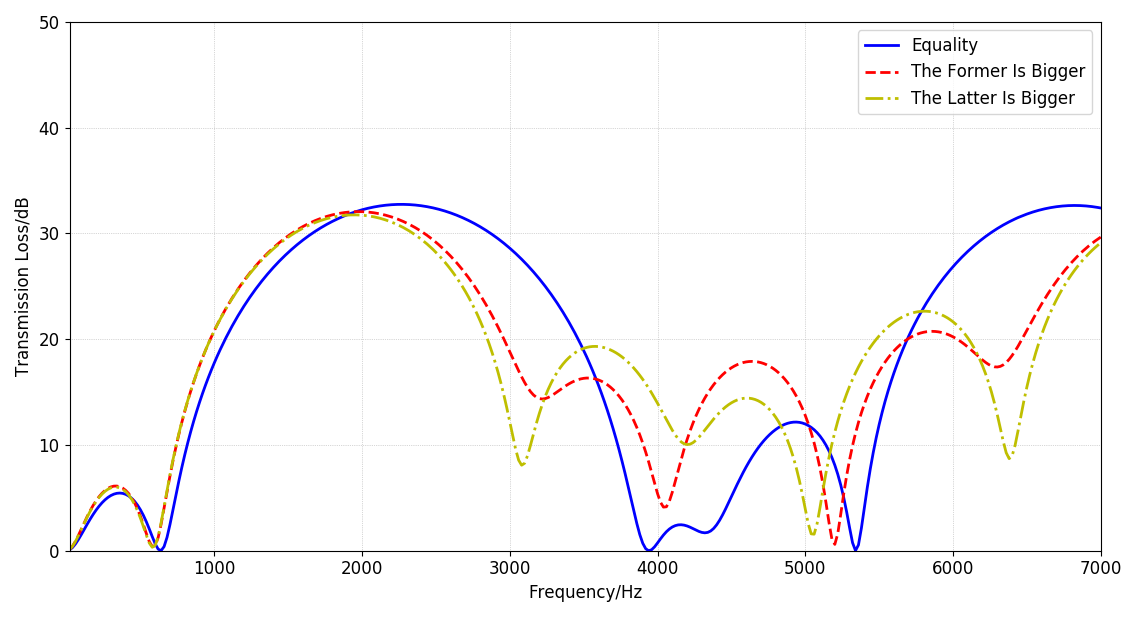

5.6. The effect of the sequence of expansion chambers with different lengths on the silencing performance

Similarly, this experiment sets up three groups of simulation experiments in ①⑫⑬ to change the order of expansion chambers of different lengths while keeping the irrelevant conditions consistent. Among them, the larger expansion chamber length is 55mm, the smaller expansion chamber length is 40mm, and the same expansion chamber length is 40mm, as shown in figure 10.

Figure 10. The effect of the sequence of expansion chambers with different lengths on the silencing performance

The analysis results show that the arrangement order of different expansion chambers has almost no effect on the transmission loss curve, but compared with the curve with the same muffler length, it can be found that the number of zeros of the transmission loss curve of the muffler with different length is less, so when the number of expansion chamber is determined, the expansion chamber with different length should be selected as far as possible in series to achieve the optimal noise suppression performance.

6. Conclusion

In order to obtain the influence of different parameters on the noise suppression performance of multi-section expansion chamber muffler, two cylindrical expansion chamber silencers are designed as reference models. By changing the number of sections of the expansion chamber of the muffler, the diameter of the cross-section of the front and rear expansion chamber, the length of the front and rear expansion chamber, the length of the connecting pipe and the arrangement order of the expansion chamber with different cross-section area and different length. Through simulation experiments, the following conclusions are obtained:

(1) Increasing the number of expansion rooms can effectively increase the muffling volume. When the installation space of the silencer is limited, the number of expansion rooms can be increased to improve the noise suppression performance.

(2) When the cross-section diameter of the front and rear expansion chamber is equal, the larger the cross-section diameter of the expansion chamber is, the greater the sound attenuation of the multi-section expansion chamber silencer is, and the better the sound suppression performance is; when the cross-section diameter of the front and rear expansion chamber is not equal, the arrangement order of different diameter expansion chambers has little influence on the muffler performance.

(3) When the length of the front and rear expansion chamber is equal, the length of the expansion chamber does not affect the peak value of the transfer loss curve, but only affects the span of the transfer loss curve; when the length of the front and rear expansion chamber is different, the arrangement order of the expansion chamber of different length changes, and the peak value of the transfer loss is basically unchanged, but the zero of the curve decreases. When the number of expansion rooms is determined, expansion chambers with different lengths should be selected for series connection as far as possible.

(4) The change in the length of the connecting pipe affects the span of the transfer loss curve, but the peak value of the transfer loss curve is basically unaffected.

This paper mainly follows the single-factor principle, which is carried out on the basis of controlling the change of one factor and keeping the other factors unchanged. Hence the influence of the interaction of multiple factors on the expansion chamber muffler is unclear. More scholars are needed to carry out further research.

References

[1]. Guo Zhengyang, Fan Chuangbi, Zhang Fan, et al. Type selection and structure design of exhaust muffler for cruise chimney [J]. Ship and Sea Engineering, 20247.53 (02): 76-80.

[2]. Liu Xiao Ang, Han Zikang, Li Hao, et al. Energy analysis and optimization of flexible wall expansion silencer [J]. Vibration and impact, 2023,542 (21): 142-148.

[3]. Zheng Rongju. Study on optimal Design of Motorcycle silencer [J]. Internal Combustion engines and fittings, 2021, (07): 18-19.

[4]. Shi Jianfeng. Simulation analysis of transmission loss of double expansion cavity series muffler [J]. Scientific and Technological Innovation and Application, 2016, (01): 87-88.

[5]. Han Lei, Ji Hongli, Qiu Jinhao, et al. Analysis of acoustic characteristics of two-stage series expansion cavity muffler [J]. Journal of Applied Mechanics, 2018. 35 (01): 60-64. 227.

[6]. Chen Guoping, Ren Zhidong, Zhang Jinnan, et al. Simulation Analysis of Noise Transmission Loss of Series Muffler [C] / China Household Electrical Appliances Association. Proceedings of China Household Electrical Appliances Technology Conference 2023. Research and Development Center of Hisense Household Appliances Group Co., Ltd.; Hisense Air Conditioning Co., Ltd.

[7]. Deng Zhaoxiang, Xiang Fei, Li Peiran, et al. Analysis of pressure loss response of expansion silencer by expansion ratio [J]. Automobile Engineering, 2011 jue 33 (03): 231235.

[8]. Liu Fei, Lu Lin, Liu Hongguang, et al. Finite element analysis of acoustic characteristics of expansion chamber muffler [J]. Noise and Vibration Control, 2010 Pol 30 (03): 144-147.

[9]. Zhou Zhihao. Design and performance analysis of diesel engine exhaust muffler [D]. Shanghai Institute of Applied Technology, 2015.

[10]. Gao Zhiqiang, Xia Qiang, Wu Junhong. Optimal design and selection of air conditioner series silencer [J]. Household Appliances, 2020, (10): 50-53.

[11]. Hou Qinzhong. Simulation and optimization of vehicle muffler based on computational fluid dynamics [D]. Shandong Jiaotong University, 2022.

[12]. Yang Xin, Chen Xinjie, Zhang Wei, et al. A comprehensive study on acoustic characteristics and fluid properties of suction silencer of reciprocating compression machine [J]. Home Electric Technology, 2024, (01): 92-96.

[13]. Li Wu, Xiao Jian, Ji Han. Simulation analysis and optimization of air conditioning silencer based on finite element method [J]. Household Electrical Appliances, 2024, (02): 117,121.

Cite this article

Huang,L. (2024). Design and performance analysis of multi-section expansion chamber muffler based on Actran. Theoretical and Natural Science,53,31-40.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Applied Physics and Mathematical Modeling

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Guo Zhengyang, Fan Chuangbi, Zhang Fan, et al. Type selection and structure design of exhaust muffler for cruise chimney [J]. Ship and Sea Engineering, 20247.53 (02): 76-80.

[2]. Liu Xiao Ang, Han Zikang, Li Hao, et al. Energy analysis and optimization of flexible wall expansion silencer [J]. Vibration and impact, 2023,542 (21): 142-148.

[3]. Zheng Rongju. Study on optimal Design of Motorcycle silencer [J]. Internal Combustion engines and fittings, 2021, (07): 18-19.

[4]. Shi Jianfeng. Simulation analysis of transmission loss of double expansion cavity series muffler [J]. Scientific and Technological Innovation and Application, 2016, (01): 87-88.

[5]. Han Lei, Ji Hongli, Qiu Jinhao, et al. Analysis of acoustic characteristics of two-stage series expansion cavity muffler [J]. Journal of Applied Mechanics, 2018. 35 (01): 60-64. 227.

[6]. Chen Guoping, Ren Zhidong, Zhang Jinnan, et al. Simulation Analysis of Noise Transmission Loss of Series Muffler [C] / China Household Electrical Appliances Association. Proceedings of China Household Electrical Appliances Technology Conference 2023. Research and Development Center of Hisense Household Appliances Group Co., Ltd.; Hisense Air Conditioning Co., Ltd.

[7]. Deng Zhaoxiang, Xiang Fei, Li Peiran, et al. Analysis of pressure loss response of expansion silencer by expansion ratio [J]. Automobile Engineering, 2011 jue 33 (03): 231235.

[8]. Liu Fei, Lu Lin, Liu Hongguang, et al. Finite element analysis of acoustic characteristics of expansion chamber muffler [J]. Noise and Vibration Control, 2010 Pol 30 (03): 144-147.

[9]. Zhou Zhihao. Design and performance analysis of diesel engine exhaust muffler [D]. Shanghai Institute of Applied Technology, 2015.

[10]. Gao Zhiqiang, Xia Qiang, Wu Junhong. Optimal design and selection of air conditioner series silencer [J]. Household Appliances, 2020, (10): 50-53.

[11]. Hou Qinzhong. Simulation and optimization of vehicle muffler based on computational fluid dynamics [D]. Shandong Jiaotong University, 2022.

[12]. Yang Xin, Chen Xinjie, Zhang Wei, et al. A comprehensive study on acoustic characteristics and fluid properties of suction silencer of reciprocating compression machine [J]. Home Electric Technology, 2024, (01): 92-96.

[13]. Li Wu, Xiao Jian, Ji Han. Simulation analysis and optimization of air conditioning silencer based on finite element method [J]. Household Electrical Appliances, 2024, (02): 117,121.