1. Introduction

With the advent of the new retail era, the fresh e-commerce industry is booming. As a benchmark enterprise in the field of fresh e-commerce, Hema Fresh has stood out in the fierce market competition by virtue of its innovative business format that integrates online and offline with modern logistics. As an economically developed and densely populated area in Pudong New Area of Shanghai, Hema Fresh has many stores and a large number of consumers. However, the complex traffic situation and diverse consumer demands in Pudong New Area make Hema's logistics and distribution face severe challenges. Optimizing the logistics distribution route can not only improve the distribution efficiency and reduce the logistics cost, but also ensure the quality of products and enhance customer satisfaction. Therefore, this paper aims to analyze the problems existing in the existing distribution routes of Hema Fresh food through scientific methods and models, explore more efficient and reliable optimization strategies, and provide beneficial references for the logistics distribution development of Hema fresh food and other fresh e-commerce enterprises.

2. Background of the problem

2.1. Overview of Hema Fresh

Hema is a self-operated fresh and daily necessities retail supermarket chain owned by Alibaba. It is China's first new retail platform and pioneer of new retail driven by data and technology. It is an innovative business format that fully integrates online, offline and modern logistics. Founded in 2015, Hema opened its first store on January 15, 2016. It mainly sells fresh food, which consumers can buy in the store or place orders in the Hema App. It uses big data, mobile Internet, intelligent Internet of things, automation and other technologies and equipment to achieve the optimal match between people, goods and fields, from supply chain, warehousing to distribution are equipped with their own complete logistics system; Its business is based on the "1+3" mode, using different formats of large and small size to serve different types of users, among which, "1" refers to Hema Fresh, "3" includes Hema X member store, Hema neighborhood and fresh Ole. By the end of December 2024, Hema Fresh has a self-owned supply chain operation center and more than 20 offline stores in Pudong New Area of Shanghai. In recent years, Hema has been developing continuously, advancing with The Times, and constantly improving its market competitiveness. Hema is committed to meeting consumers' yearning for a better life, and leading thousands of families to "fresh, beautiful and life" with technology and innovation.

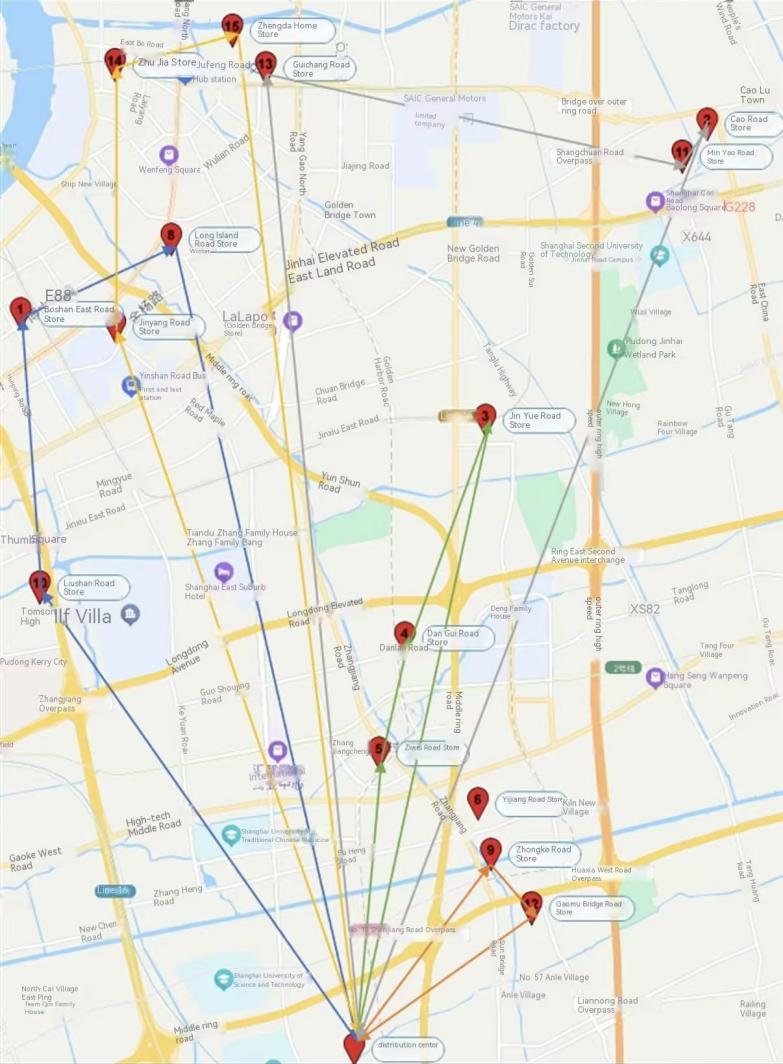

The distribution of the 15 Hema Fresh Food distribution points selected in this paper in Shanghai Pudong New Area is shown in Figure 1:

Figure 1: Distribution of distribution points.

Table 1 shows Hema Fresh’s current distribution center in Pudong New Area of Shanghai, as well as the specific situation of the geographical location and demand of the 15 distribution points.

Table 1: Number, location and demand of distribution centers and distribution points.

Addresses | Number | Longitude (X) | Latitude (Y) | Quantity demanded |

Distribution center | 0 | 121.61 | 31.04 | 0 |

Boshan East Road store, Pudong | 1 | 127.57 | 31.25 | 3.6 |

Caolu Store, Pudong | 2 | 121.66 | 31.27 | 3.9 |

Jinyue Road Store, Pudong | 3 | 121.63 | 31.24 | 2.8 |

Dangui Road Store, Pudong | 4 | 121.62 | 31.21 | 3.4 |

Ziwei Road Store, Pudong | 5 | 121.62 | 31.20 | 3.3 |

Yijiang Road Store, Pudong | 6 | 121.63 | 31.20 | 2.8 |

Jinyang Road Store, Pudong | 7 | 121.58 | 31.25 | 4.5 |

Changdao Road Store, Pudong | 8 | 121.59 | 31.26 | 4.0 |

Zhongke Road Store, Pudong | 9 | 121.63 | 31.19 | 3.5 |

Liushan Road Store, Pudong | 10 | 121.57 | 31.22 | 2.4 |

Minyao Road Store, Pudong | 11 | 121.66 | 31.27 | 3.1 |

Gaomuqiao Road Store, Pudong | 12 | 121.64 | 31.18 | 2.5 |

Guichang Road Store, Pudong | 13 | 121.60 | 31.28 | 1.8 |

ZhuJiamen Store, Pudong | 14 | 121.58 | 31.28 | 2.3 |

Zhengda Homeland Store, Pudong | 15 | 121.60 | 31.28 | 3.2 |

2.2. Distribution mode status

Hema Fresh has a very diversified distribution mode. On the one hand, for consumers within 3 kilometers of the store, it provides fast and immediate delivery services to ensure the delivery of fresh goods within 30 minutes; On the other hand, for many offline stores, both suppliers directly deliver to the store, but also through a strong regional distribution center, integrate supplier goods and unified distribution to the store. In addition, there is also a pre-warehouse mode, which is positioned in densely populated areas to quickly respond to surrounding orders and greatly shorten the delivery time. This paper discusses the route optimization problem of Hema fresh biological flow distribution when the distribution center distributes to 15 chain stores.

2.3. Problems existing in the distribution path of the Hema Fresh biological flow

(1) Problems related to traffic factors. There is a large traffic flow in Pudong New Area, which is prone to traffic congestion, resulting in extended delivery time.

(2) Distribution distance and layout problems. The distribution of Hema Fresh stores in Pudong New Area may be uneven, resulting in too far distance from the distribution center to some stores, which increases the distribution cost and time. The distribution scope of different stores may overlap to a certain extent, which may result in multiple delivery vehicles traveling to and from the same area, increasing transportation costs.

(3) Distribution efficiency problem. As the distribution route planning is not optimized enough, there may be problems such as long distance of empty vehicles and detour of routes, resulting in low distribution efficiency. In addition, it may be necessary to load and unload goods several times during the distribution process, which will also consume a certain amount of time and reduce the

3. Construction of Hema fresh delivery route optimization model

3.1. Model Assumptions

In the process of studying the biological flow distribution of Hema Fresh in Pudong New Area of Shanghai, this paper adopts the distribution mode of single-yard and single-model problem. Therefore, to make the optimized model more suitable for the actual demand of Hema Fresh, this paper makes the following assumptions:

(1) The location information of the distribution center and distribution point is known.

(2) One vehicle can distribute multiple distribution points, but each distribution point can only be distributed by one vehicle.

(3) The capacity of the distribution vehicle is limited, and the specifications are uniform.

(4) The demand of each distribution point is known, and one distribution must meet all the needs of the distribution point.

(5) The distribution vehicle starts from the distribution center and returns to the distribution center after completing the distribution task.

(6) The speed of the vehicle is fixed and uniform, and the distance of the road and the transportation cost are known.

3.2. Parameter Settings

Table 2 lists the parameters used in this document and their meanings.

Table 2: Lists the parameter Settings.

Parameter Symbols | Parameter meaning |

i, j | Distribution point number, i=0,1,2..., n (0 stands for distribution center) |

q | Number of delivery vehicles |

h | Delivery vehicle number, h=1, 2, ...,q |

Q | The maximum load of the delivery vehicle |

\( {D_{ij}} \) | The distance between distribution points |

c | Shipping costs per unit distance |

\( {X_{ijh}}=\begin{cases} \begin{array}{c} 1,Vehicle h is traveling within the interval (i, j) \\ 0,otherwise \end{array} \end{cases} \) | |

\( {y_{jh}}=\begin{cases} \begin{array}{c} 1,Delivery point j is serviced by vehicleh \\ 0,otherwise \end{array} \end{cases} \) | |

\( {R_{j}} \) | Quantity of goods required at distribution point j |

3.3. Constraints

The mathematical model established in this paper has the following three constraints.

1.The vehicle starts from the distribution center and eventually returns to the distribution center.

\( \sum _{j=1}^{n}{X_{0jh}}=1 \) \( \sum _{i=1}^{n}{X_{j0h}}=1 \)

2.Each distribution point only needs to deliver once to complete the distribution task.

\( \sum _{h=1}^{q}{y_{jh}}=1 \) \( \sum _{i=0}^{n}{X_{ijh}}={y_{jh}} \)

3.The total amount of cargo carried by each vehicle does not exceed its maximum load.

\( \sum _{i=0}^{n}\sum _{j=1}^{n}{R_{j}}{X_{ijh}}≤Q \)

3.4. Build the Model

In this paper, Hema fresh biological flow in Pudong New Area of Shanghai is taken as the research object. Based on the actual situation of Hema Fresh, the transportation cost of logistics distribution is taken as the goal to ensure that the goods can be delivered to the distribution point intact. The target cost only considers the variable cost.

In order to facilitate the construction of the model, the assumption put forward in this paper is that the driving speed of the distribution vehicle is known and maintains a constant speed, so the influence of the secondary speed on the fuel consumption is not considered. The influence of the weight of goods in the distribution process is not considered, only the variable cost caused by the change of transportation distance is considered.

The variable cost, that is, the final overall optimization objective, is expressed as follows:

\( min{Z}=\sum _{h=1}^{q}\sum _{i=0}^{n}\sum _{j=0}^{n}c*{D_{ij}}*{X_{ijh}} \)

4. Model introduction

4.1. Greedy algorithm

4.1.1. Concept of greedy algorithm

Greedy Algorithm, also known as greedy algorithm, is an algorithm that takes the optimal choice in the current state in each step of selection, hoping that the final result is the global optimal solution. It is usually used to solve optimization problems, that is, to find the maximum or minimum value of some objective function under given constraints.

4.1.2. Characteristics of greedy algorithms

Greedy algorithm is a local optimization algorithm. Greedy algorithm has the following characteristics:

(1) The greedy algorithm is usually relatively simple to implement, the time complexity is relatively low, and in most cases it can quickly find feasible solutions.

(2) Greedy algorithms do not reconsider their previous choices after they have made them.

(3) The greedy algorithm only considers the current optimal choice when making a decision at each step, and does not consider all possible scenarios of the overall problem. It always chooses the local optimal solution, hoping to reach the global optimal through a series of local optimal decisions.

4.2. Genetic Algorithm

4.2.1. Concept of Genetic algorithm

Genetic Algorithm (GA) is a random search algorithm based on the principles of natural selection and genetic genetics, which simulates the evolutionary process of "survival of the fittest, survival of the fittest" in the natural biological world, and seeks the optimal solution or near-optimal solution through group search and genetic operations.

4.2.2. Characteristics of Genetic algorithm

Genetic algorithm is a global optimization algorithm, and the characteristics of genetic algorithm are as follows:

(1) Genetic algorithm starts from multiple initial solutions to search in parallel, can find the optimal solution in a large solution space, and is not easy to fall into the local optimal.

(2) Using natural selection and genetic mechanism in biological evolution, genetic algorithm has certain intelligence and adaptability, and can automatically adjust the search direction according to the feedback information of the problem.

(3) The dependence of genetic algorithm on problems is relatively small, and it is suitable for various types of problems.

5. The model solution and result description

5.1. Data combing

5.1.1. Distribution point information

The geographical location of the distribution point can be found by the longitude and latitude coordinates of the Autonavi map, and the demand can be estimated by the possible pedestrian flow of each store in Hema Fresh, Pudong New Area, Shanghai. In order to make the result more in line with the actual situation, this paper fully considers the actual situation, and obtains the transportation distance of the actual distribution vehicle through the Amap map (select the recommended scheme type between two points) to represent the spatial distance, rather than the shortest linear distance between nodes. The specific relative distance is shown in Table 3, where 0-15 in the first row and first column represent the distribution center and the corresponding 15 distribution points.

Table 3: Relative distance between distribution points.

0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

0 | 0 | 25.8 | 33.7 | 26.2 | 24.0 | 23.0 | 22.0 | 25.8 | 27.7 | 23.4 | 22.6 | 33.3 | 23.3 | 31.0 | 29.6 | 31.5 |

1 | 25.8 | 0 | 11.5 | 7.6 | 8.3 | 9.2 | 11.8 | 1.7 | 2.7 | 12.2 | 4.0 | 11.7 | 13.0 | 5.2 | 3.9 | 5.8 |

2 | 33.7 | 11.5 | 0 | 6.6 | 10.0 | 11.7 | 11.8 | 9.7 | 8.7 | 12.1 | 12.9 | 0.91 | 12.6 | 6.8 | 8.6 | 7.2 |

3 | 26.2 | 7.6 | 6.6 | 0 | 3.8 | 5.2 | 6.0 | 6.0 | 6.1 | 6.6 | 6.7 | 6.1 | 7.1 | 5.9 | 7.6 | 7.1 |

4 | 24.0 | 8.3 | 10.0 | 3.8 | 0 | 1.9 | 3.1 | 6.8 | 7.2 | 3.7 | 6.8 | 9.5 | 4.6 | 8.8 | 9.1 | 10.2 |

5 | 23.0 | 9.2 | 11.7 | 5.2 | 1.9 | 0 | 1.9 | 7.7 | 8.0 | 2.6 | 7.7 | 10.9 | 3.4 | 10.6 | 9.9 | 11.0 |

6 | 22.0 | 11.8 | 11.8 | 6.0 | 3.1 | 1.9 | 0 | 9.1 | 9.5 | 1.3 | 9.1 | 11.5 | 2.1 | 11.1 | 12.3 | 13.4 |

7 | 25.8 | 1.7 | 9.7 | 6.0 | 6.8 | 7.7 | 9.1 | 0 | 2.0 | 9.5 | 4.1 | 9.5 | 12.5 | 4.6 | 4.0 | 5.2 |

8 | 27.7 | 2.7 | 8.7 | 6.1 | 7.2 | 8.0 | 9.5 | 2.0 | 0 | 10.0 | 5.7 | 7.8 | 11.9 | 2.9 | 2.3 | 3.5 |

9 | 23.4 | 12.2 | 12.1 | 6.6 | 3.7 | 2.6 | 1.3 | 9.5 | 10.0 | 0 | 9.7 | 12.6 | 1.2 | 12.6 | 12.9 | 14.0 |

10 | 22.6 | 4.0 | 12.9 | 6.7 | 6.8 | 7.7 | 9.1 | 4.1 | 5.7 | 9.7 | 0 | 12.2 | 10.7 | 8.2 | 7.7 | 8.8 |

11 | 33.3 | 11.7 | 0.91 | 6.1 | 9.5 | 10.9 | 11.5 | 9.5 | 7.8 | 12.6 | 12.2 | 0 | 11.3 | 6.5 | 8.3 | 7.0 |

12 | 23.3 | 13.0 | 12.6 | 7.1 | 4.6 | 13.4 | 2.1 | 12.5 | 11.9 | 1.2 | 10.7 | 11.3 | 0 | 14.4 | 13.7 | 14.8 |

13 | 31.0 | 5.2 | 6.8 | 5.9 | 8.8 | 10.6 | 11.1 | 4.6 | 2.9 | 12.6 | 8.2 | 6.5 | 14.4 | 0 | 2.6 | 1.2 |

14 | 29.6 | 3.9 | 8.6 | 7.6 | 9.1 | 9.9 | 12.3 | 4.0 | 2.3 | 12.9 | 7.7 | 8.3 | 13.7 | 2.6 | 0 | 2.0 |

15 | 31.5 | 5.8 | 7.2 | 7.1 | 10.2 | 11.0 | 13.4 | 5.2 | 3.5 | 14.0 | 8.8 | 7.0 | 14.8 | 1.2 | 2.0 | 0 |

5.1.2. Model parameters

The cars used for the distribution of Hema Fresh in Pudong New Area of Shanghai are of the same model. The maximum load capacity of each car is 10 tons and the number of vehicles is 5. The vehicle unit distance transportation cost is composed of many influencing factors, so it is assumed in this paper that the vehicle unit distance transportation cost is 3 yuan/km.

5.2. Model Solving

5.2.1. Greedy algorithm solution process

According to the constructed mathematical model, this paper uses Matlab software to write the greedy algorithm program code, the specific solving steps are as follows:

(1) Determine the greedy strategy. Study the nature and structure of the problem and determine specific greedy strategies based on the characteristics of the problem. The greedy strategy adopted in this paper is as follows: for each vehicle, on the premise of meeting the maximum load capacity of the vehicle, each time choose the nearest and visited distribution point from the current location as the next distribution point.

(2) Data initialization. This paper initializes the total number of distribution centers and distribution points, the number of vehicles, the load of vehicles and the distance matrix.

(3) Iterative selection, update and termination of greedy algorithm. In accordance with the greedy strategy, select the locally optimal option from the current alternatives at each step. Each step in this article selects the next distribution point from the nearest and accessible distribution point to the current location.

The updating process of the greedy algorithm is to update the relevant data structure and state information after each greedy choice is made. In this paper, after selecting a new distribution point as part of the shortest path, the current load and node are updated.

The termination process of greedy algorithm is to check whether the termination condition is met after each iteration. The termination condition in this article is that all vehicles have completed the path planning, or all distribution points have been visited, or a vehicle cannot carry any more cargo.

(4) Construct the optimal path. According to the final data structure and state information, the optimal path is constructed retrospectively, and the obtained optimal path is output in a suitable form.

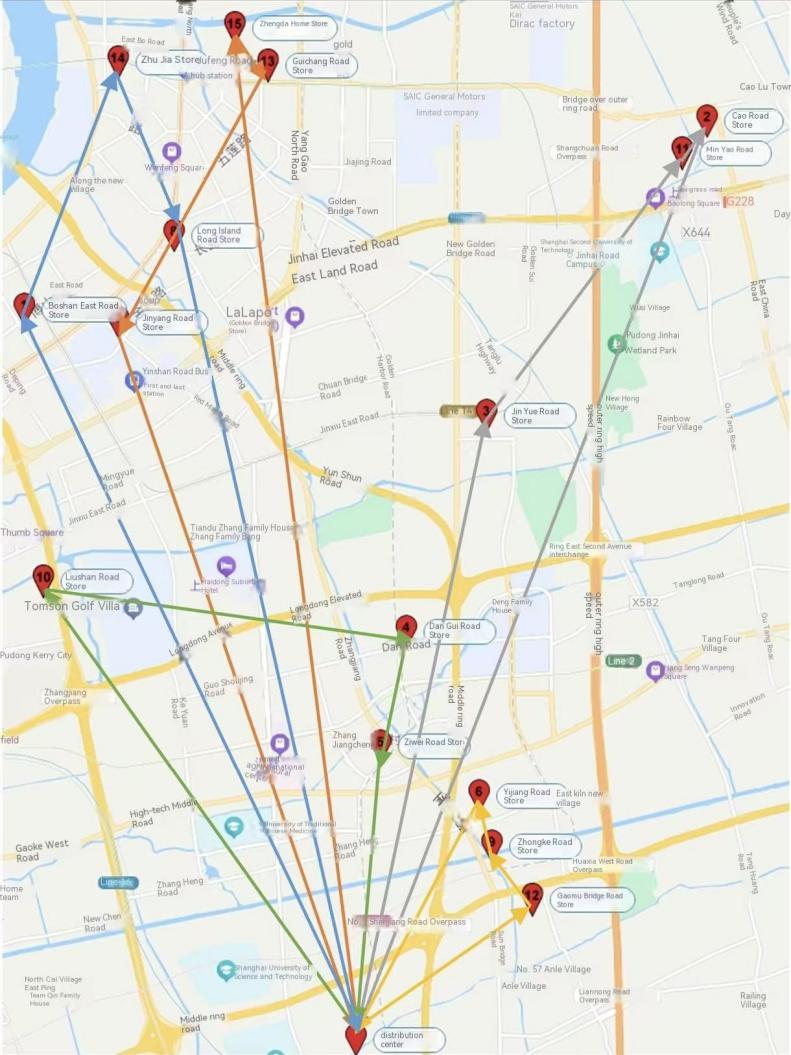

Based on the above methods, this paper uses Matlab software to write the greedy algorithm code, and finally calculates the results, obtaining the approximate optimal solution 885.33, and outputs the optimized distribution path, as shown in Table 4:

Table 4: optimal distribution path under the greedy algorithm.

Vehicle number | Delivery path | Load capacity | Load rate | Total distance traveled |

1 | 0-6-9-12-0 | 8.8 | 88% | 47.8 |

2 | 0-10-1-8-0 | 10 | 100% | 57 |

3 | 0-5-4-3-0 | 9.5 | 95% | 54.9 |

4 | 0-7-14-15-0 | 10 | 100% | 63.3 |

5 | 0-13-11-20 | 8.8 | 88% | 72.11 |

After optimization, the specific store distribution route is as follows and the distribution route diagram is shown in Figure 2:

(1) Distribution center - Pudong Yijiang Road Store - Pudong Zhongke Road Store - Pudong Gaomuqiao Road store - Distribution center

(2) Distribution Center - Pudong Liushan Road Store - Pudong Boshan East Road store - Pudong Changdao Road store - Distribution center

(3) Distribution Center - Pudong Ziwei Road Store - Pudong Dangui Road store - Pudong Jinyue Road store - Distribution center

(4) Distribution Center - Pudong Jinyang Road Store - Pudong Zhujiamen Store - Pudong Zhengda Homeland Store - Distribution center

(5) Distribution Center - Pudong Guichang Road Store - Pudong Minyao Road Store - Pudong Caolu Store - Distribution center

5.2.2. Genetic Algorithm solution process

According to the mathematical model, the genetic algorithm code is written by Matlab software. The specific solving steps are as follows:

(1) Problem coding. This paper uses the real number coding method to select a total of 15 Hema fresh delivery points in Pudong New Area of Shanghai, a distribution center. The number of distribution center is 0, and the number of other distribution points is 1-15 respectively.

(2) Initialize the population. Randomly generate a certain number of individuals to serve as the initial population. A total of 15 fresh Hema distribution points in Pudong New Area of Shanghai were selected. In order to obtain more accurate results, the population number was set to 100 in this paper.

(3) Calculate the fitness. Define the fitness function to evaluate the merits and disadvantages of the individual. In this paper, the transportation cost is taken as the objective function, and the Fitness is inversely proportional to the objective function, so the fitness function can be expressed as Fitness=1/F.

(4) Selection, crossover and variation of genetic algorithm. According to the fitness value of the individual, some individuals are selected from the current population as the parent individuals of the next generation population.The objective function value of optimization of distribution route studied in this paper is cost, and the smaller the cost, the better.Therefore, replace the lower individuals with the higher fitness value, and finally the new population generated is the required size value.

The crossover process of genetic algorithm is to carry out crossover operations on the selected parent individuals to generate new offspring individuals. A total of 15 Hema fresh distribution points in Pudong New Area of Shanghai are selected. In order to obtain more accurate results, the crossover probability is set at 0.8 in this paper.

The mutation of genetic algorithm is to carry out the mutation operation on the newly generated progeny individual with a certain mutation probability to simulate the process of gene mutation in biological inheritance.In this paper, the exchange mutation method is used to carry out the mutation. In order to obtain more accurate results, the mutation probability is set at 0.1.

(5) Termination.In this paper, the number of iterations is set to 500, and the algorithm is ended after 500 iterations to get the optimal solution.

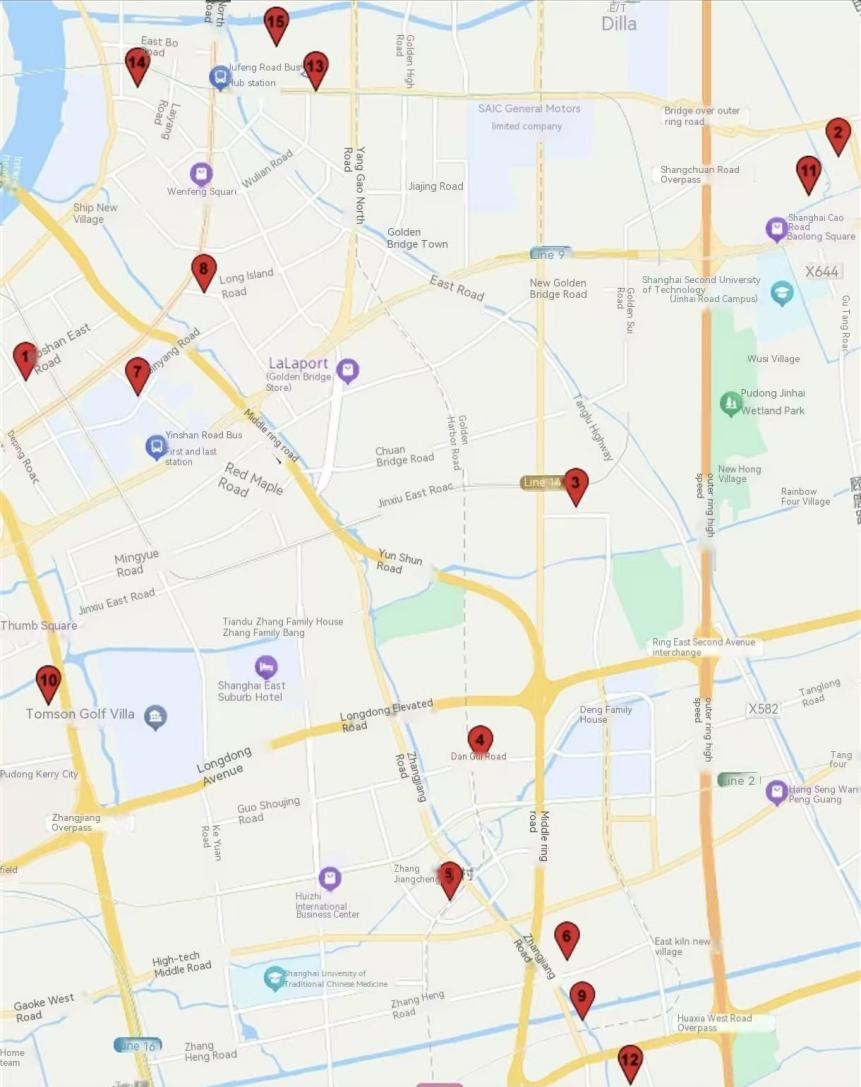

According to the above method, this paper uses Matlab software to write the genetic algorithm code, and finally calculates the result, obtaining the approximate optimal solution 875.43, and outputs the optimized distribution path, as shown in Table 5:

Table 5: optimal distribution path under genetic algorithm.

Vehicle number | Delivery path | Load capacity | Load rate | Total distance traveled |

1 | 0-3-11-2-0 | 9.8 | 98% | 66.91 |

2 | 0-15-13-7-0 | 9.5 | 95% | 63.1 |

3 | 0-10-4-5-0 | 9.1 | 91% | 54.3 |

4 | 0-12-9-6-0 | 8.8 | 88% | 47.7 |

5 | 0-1-14-8-0 | 9.9 | 99% | 59.7 |

After optimization, the specific store distribution route is as follows and the distribution route diagram is shown in Figure 3:

(1) Distribution center - Pudong Jinyue Road Store - Pudong Minyao Road Store - Pudong Caolu Store - Distribution center

(2) Distribution Center - Pudong Zhengda Homeland Store - Pudong Guichang Road Store - Pudong Jinyang Road store - Distribution center

(3) Distribution Center - Pudong Liushan Road - Pudong Dangui Road Store - Pudong Ziwei Road store - Distribution center

(4) Distribution Center - Pudong Gaomuqiao Road Store - Pudong Zhongke Road Store - Pudong Yijiang Road store - Distribution center

(5) Distribution Center - Pudong Boshan East Road Store - Pudong Zhujiamen Store - Pudong Changdao Road Store - Distribution center

|

|

Figure 2: Optimal distribution roadmap based on greedy algorithm. | Figure 3: Optimal distribution roadmap based on genetic algorithm. |

For the convenience of drawing, the location of the distribution center in the figure above is not the location of the actual distribution center.

5.3. Description of optimization results

The transportation cost after greedy algorithm optimization is 885.33 yuan, the total distance is 295.11 kilometers, the load rate of five vehicles is 88%, 100%, 95%, 100%, 88%, and the average load rate is 94.2%. After the optimization of genetic algorithm, the transportation cost is 875.43 yuan, the total distance is 291.71 kilometers, and the load rate of five vehicles is 98%, 95%, 91%, 88%, 99%, and the average load rate is 94.2%. Through comparative analysis, the genetic algorithm is superior to the greedy algorithm in terms of transportation cost and total distance, and the two are equivalent in the average load rate. It can be seen that genetic algorithm can find a better path planning scheme to reduce the transportation cost and total distance when solving the transportation path optimization problem. However, the specific choice of which algorithm, according to the needs of the actual application to decide.

6. Conclusion

6.1. Summary of research results

This paper studies the distribution route problem of single vehicle type, considering the variable cost caused by the change of transportation distance, which has practical significance. At the same time, cost minimization was used as the objective function to build a model, Matlab software was used to solve the model under the greedy algorithm and genetic algorithm respectively, and the optimal solution was obtained. The purpose of shortest distribution path and lowest distribution cost was achieved by comparative analysis, which proved the effectiveness of the model establishment.

6.2. Future outlook

The Internet of Things technology can be used to achieve real-time monitoring of distribution vehicles and goods to ensure the efficiency and safety of the entire distribution process. Besides, personalized delivery services can be introduced to flexibly plan and adjust delivery paths according to different needs of consumers, so as to improve customer experience and satisfaction.

References

[1]. Li Xiannan. Research on optimization of logistics distribution path of M supermarket. [D]. North University of China, 2023.

[2]. Wang Luping. Research on Cold chain Distribution Center location of fresh e-commerce under new retail environment [D]. Huaqiao University, 2019.

[3]. Guo Jia. Research on Logistics Distribution Route Optimization of Electric refrigerated Truck based on Improved Genetic Algorithm [D]. Tianjin University of Technology, 2023.

[4]. Ying Shanqiang. Research on Optimization of pre-production logistics transportation route in Automobile Industry [D]. Harbin Institute of Technology, 2005.

[5]. Xu Weihua, Qiu Longlong, Zhang Genrui, et al. Improved Genetic Algorithm for Vehicle Routing Problem with Capacity Constraints [J]. Computer Engineering and Design, 2024, 45 (03): 785-792.

[6]. WEI Zi-heng, Chen Zhi-De. Research on Optimization method of UAV path planning based on Mathematical Modeling and Genetic Algorithm [J]. Computer knowledge and technology, 2024, 20 (36) : 45-48, DOI: 10.14004 / j.carol carroll nki CKT. 2024.1861.

[7]. He Wenlong, Xu Hao, Bi Deming, et al. Based on improved ant colony algorithm of fresh distribution path optimization research [J]. Journal of gansu science, 2024, 36 (6) : 108-113 + 152. DOI: 10.16468 / j.carol carroll nki issn1004-0366.2024.06.016.

[8]. Wang Jinyu, Yuan Kai, Song Bing, et al. Low carbon cold chain logistics distribution path optimization based on improved Genetic algorithm [J]. Logistics Engineering and Management, 2024, 46 (11): 26-31.

[9]. Xu Hao, He Wenlong, Lin Xian-Hui, et al. Research on Optimization of urban fresh cold chain logistics distribution route considering carbon emission [J]. Logistics Technology, 2024, 47 (15): 147-150+ 155.DOI :10.13714/j.cnki.1002-3100.2024.15.036.

[10]. Li Nan, Xin Chunyang. Urban Logistics Distribution route Optimization of "Vehicle + Drone" based on cluster-Floyd-Genetic Algorithm [J]. Science Technology and Engineering, 2024, 24 (21): 9186-9193.

Cite this article

Fu,J. (2025). The Application of Mathematics in Logistics Distribution Optimization. Theoretical and Natural Science,101,89-98.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MPCS 2025 Symposium: Mastering Optimization: Strategies for Maximum Efficiency

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Li Xiannan. Research on optimization of logistics distribution path of M supermarket. [D]. North University of China, 2023.

[2]. Wang Luping. Research on Cold chain Distribution Center location of fresh e-commerce under new retail environment [D]. Huaqiao University, 2019.

[3]. Guo Jia. Research on Logistics Distribution Route Optimization of Electric refrigerated Truck based on Improved Genetic Algorithm [D]. Tianjin University of Technology, 2023.

[4]. Ying Shanqiang. Research on Optimization of pre-production logistics transportation route in Automobile Industry [D]. Harbin Institute of Technology, 2005.

[5]. Xu Weihua, Qiu Longlong, Zhang Genrui, et al. Improved Genetic Algorithm for Vehicle Routing Problem with Capacity Constraints [J]. Computer Engineering and Design, 2024, 45 (03): 785-792.

[6]. WEI Zi-heng, Chen Zhi-De. Research on Optimization method of UAV path planning based on Mathematical Modeling and Genetic Algorithm [J]. Computer knowledge and technology, 2024, 20 (36) : 45-48, DOI: 10.14004 / j.carol carroll nki CKT. 2024.1861.

[7]. He Wenlong, Xu Hao, Bi Deming, et al. Based on improved ant colony algorithm of fresh distribution path optimization research [J]. Journal of gansu science, 2024, 36 (6) : 108-113 + 152. DOI: 10.16468 / j.carol carroll nki issn1004-0366.2024.06.016.

[8]. Wang Jinyu, Yuan Kai, Song Bing, et al. Low carbon cold chain logistics distribution path optimization based on improved Genetic algorithm [J]. Logistics Engineering and Management, 2024, 46 (11): 26-31.

[9]. Xu Hao, He Wenlong, Lin Xian-Hui, et al. Research on Optimization of urban fresh cold chain logistics distribution route considering carbon emission [J]. Logistics Technology, 2024, 47 (15): 147-150+ 155.DOI :10.13714/j.cnki.1002-3100.2024.15.036.

[10]. Li Nan, Xin Chunyang. Urban Logistics Distribution route Optimization of "Vehicle + Drone" based on cluster-Floyd-Genetic Algorithm [J]. Science Technology and Engineering, 2024, 24 (21): 9186-9193.