1. Introduction

Soft robotic manipulators have garnered significant attention due to their adaptability in unstructured environments. However, conventional designs with circular cross-sections inherently limit torsional rigidity and directional control, making it difficult to strike a balance betweent flexibility and load-bearing capacity, and thus thus a trade-off between compliance and stiffness is necessary, particularly in high-precision tasks such as minimally invasive surgery or delicate agricultural harvesting [1]. To address these challenges, researchers and scholars are combining the biological properties of special organisms with machinery to offer new approaches to design and exploitation in related fields. The seahorse tail is a structure renowned for its unique square-prismatic vertebrae and segmented modularity, with a square cross-section that enhances resistance to compression and torsion while maintaining flexibility, a feature attributed to its interlocking bony plates and connective tissues [2]. This biomechanical duality aligns with the demands of soft robotics, where adaptive stiffness and precision are critical. Therefore, this study proposes a bionic soft robotic arm mimicking the seahorse tail’s structural principles. The seahorse tail comprises a series of square vertebral segments connected by flexible joints, enabling both bending and load-bearing through a “right-flexible” hybrid mechanism. Specifically, the square geometry distributes stress uniformly under compression, while the modular segmentation allows localized deformation without compromising global stability. These characteristics directly address the limitations of circular-section manipulators by enabling anisotropic stiffness modulation, that is, stiffness in specific directions while retaining compliance in others [1]. By replicating this architecture through 3D-prints rigid skeletons (analogous to vertebrae) and silicone-based soft joints (mimicking connective tissues), the proposed manipulator achieves tunable stiffness via pneumatic actuation. The design not only inherits the seahorse tail’s biomechanical advantages but also introduces modularity for task-specific reconfiguration, bridging biological insights with engineering applications [3].

In order to validate the design in this paper, bending analysis and airbag pressure analysis are performed on the design based on the software simulation platform ABAQUS. In the bending analysis, the robotic arm is placed upright on a flat surface, the base is fixed, and pressure is applied to its upper surface to analyze the bending direction and stress distribution of the robotic arm. Then the airbag pressure analysis is completed by analyzing the stiffness change of the robotic arm by changing the airbag pressure. The bionic square cross-section soft gripper that imitates the structure of the hippocampus tail for higher precision and stronger gripping can broaden the application of mechanics or robots in medical and agricultural scenarios. It can also fill the shortcomings of the current square robotic arm that cannot be widely used in practice, laying a foundation for subsequent research.

2. Theoretical framework

The theoretical framework establishes a quantifiable foundation to guide the design and validate the performance of the biomimetic manipulator. Specifically, two core models were developed: (1) a bending mechanics model for predicting deformation under load, and (2) a pneumatic stiffness adjustment model for mapping pressure-stiffness relationships. These models directly informed the experimental design and data interpretation in in this research.

2.1. Bending mechanics model for variable-stiffness robotic arm

The Euler-Bernoulli beam theory was adapted to characterize the static bending behavior of the modular arm under external loads [4]. The governing equation:

Where

This model served two purposes, in desigen phase, mainly to guide the selection of material properties (e.g., elastic modulus

The modular joint stiffness was modeled as a superposition of local stiffness contributions [5]:

Where

2.2. Pneumatically stiffness adjustment mechanism

The stiffness modulation relies on pressurized airbags embedded in the vertebral modules [6-7]. The relationship between airbag pressure (

Where

This model directly supported the pressure-stiffness experiment, and its primary function in the design phase is to determine the airbag geometry (radius

The ideal gas law correction incorporated viscous damping effects:

Where

2.3. Integration with biomimetic design

The integration of biological principles and engineering mechanics forms the cornerstone of this biomimetic design. By emulating the seahorse tail’s segmented square-prismatic vertebrae and interlocking ball-and-socket joints, the manipulator achieves a hybrid "rigid-flexible" architecture that mirrors biological adaptability. Specifically, the staggered alignment of modular joints (spaced at 90° intervals) replicates the seahorse’s ability to resist torsional deformation while enabling multi-axis bending, a feature that has been validated through Euler-Bernoulli beam theory and FEA simulations. Calibration of material parameters (e.g., silicone elastic modulus

2.3.1. Model design

The design of the biomimetic manipulator is rooted in the unique biomechanical features of the seahorse tail, which exhibits exceptional adaptability to bending and compression through its square-prismatic vertebral architecture and segmented modularity. According to Trivedi et al., the seahorse tail comprises a series of square osteoderms (bony plates) interconnected by flexible joints, enabling both high torsional rigidity and localized compliance [2]. Specifically, the square cross-section of each vertebral segment distributes stress uniformly under compression, while the staggered alignment of joints allows multi-axis bending with minimal energy dissipation. These biological insights informed three critical design principles [3]:

•Square Prismatic Geometry: Each skeletal module adopts a hollow square cross-section (edge length=12 mm, wall thickness=1.5 mm) to mimic the osteoderm structure, optimizing load distribution and resistance to buckling.

•Ball-and-Socket Modularity: Segments are connected via 3D-printed ball-and-socket joints (radius=3 mm) spaced at 90° intervals, replicating the interlocking mechanism of seahorse vertebrae to enable ±45° bending in orthogonal planes.

•Integrated Pneumatic Actuation: Silicone airbags (radius=3.5 mm, height=15 mm) are embedded within the vertebral cavities, leveraging pressure-driven expansion to modulate joint stiffness, akin to the seahorse’s dynamic muscular control.

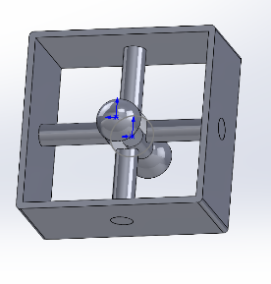

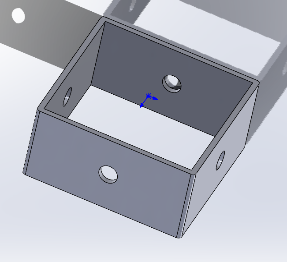

2.3.2. Description of the skeleton part

Due to the square shape of the hippony's tail skeleton, the entire segment is simplified into a square cube at the top and rectangular on all sides. At the same time, the interior is hollow, and the four vertex corners of the two square faces of the cube are rounded to avoid stress concentrations.

The cube has a circular hole in the center of the rectangle around it, which makes it easy to fit with the "spine" parts.

At the same time, the material of the part is made of 3D printing resin with an elastic modulus of 2.5Gpa, and a Poisson's ratio of 0.3 to ensure the strength and stiffness of the material [6], as figure 1 shows.

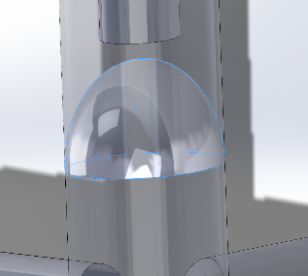

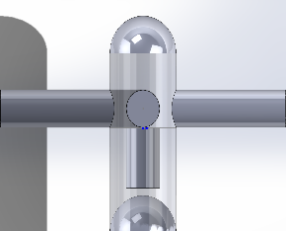

2.3.3. Spine part description

The vertebral parts are modeled after the hippocampal vertebrae with a ball-and-socket connection, while the vertebrae are connected every 90 degrees and a connector is launched. Therefore, a cylinder is first established, a hemispherical convex groove is arranged at the top of the cylinder, and a hemispherical groove with an approximately equal radius (

The material is made of silicon soft material with an elastic modulus of 50 MPa and a Poisson's ratio of 0.49 to ensure the bending and deformation of the central axis of the robotic arm.

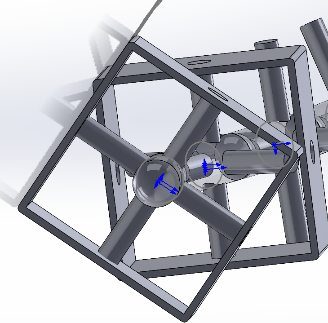

2.3.4. Part assembly

The connecting parts around the spine part are combined with the hole fixing assembly of the skeleton part, which is a section of the robotic arm. After that, the top groove of the first section is connected to the tail groove of the second section (using a magnetic suction method), as figure 3 shows. The operation is repeated four times in this way to obtain a short robotic arm composed of five sections, which is the main research object of this project.

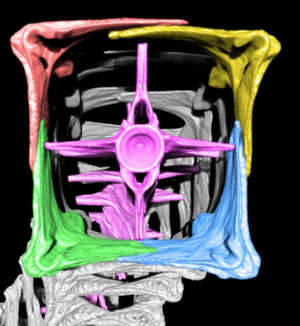

Comparing the robotic arm with the hippocampal tail skeleton, we can find good biomimicry (Figure 4).

|

|

|

Figure 3: Link details

|

|

|

| Figure 4: Comparison of the coccyx with the robotic arm | |

3. Experimental

3.1. Data resource

The connecting parts around the spine part are combined with the hole fixing assembly of the skeleton part, which is a section of the robotic arm. After that, the top groove of the first section is connected to the tail groove of the second section (using a magnetic suction method), as figure 3 shows. The operation is repeated four times in this way to obtain a short robotic arm composed of five sections, which is the main research object of this project.

Comparing the robotic arm with the hippocampal tail skeleton, we can find good biomimicry (Figure 4).

|

Parameter type |

Numeric range |

How it is applied |

Data source |

|

Static concentration |

0–100N |

The end of the robotic arm is evenly distributed |

Theoretical calculations and pre-experiments |

|

Airbag air pressure |

0–200 kPa |

Surface pressure load |

Pneumatic system calibration experiments |

3.2. Experimental process

3.2.1. Static bending and stress analysis of robotic arms

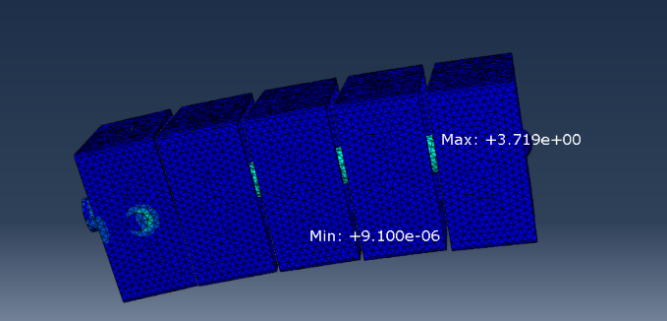

A five-section modular robotic arm model was introduced into Abaqus, with a fixed base and a normal concentrated force (100N) applied at the top. After that, the hexahedral mesh was divided and the robotic arm was meshed for analysis. Then, the general static solver was used to extract the Von Mises stress field and displacement contour diagram, and the maximum stress distribution position and bending deformation were analyzed.

3.2.2. Analysis of the effect of airbag air pressure on stiffness

Multi-conditional parametric design of the airbag is performed, and gradient pressure load (0Kpa, 100Kpa, 200Kpa) is applied to the inner surface of the airbag groove to keep other boundary conditions consistent. The equivalent stiffness is also defined

3.3. Results

3.3.1. Static bending characteristics

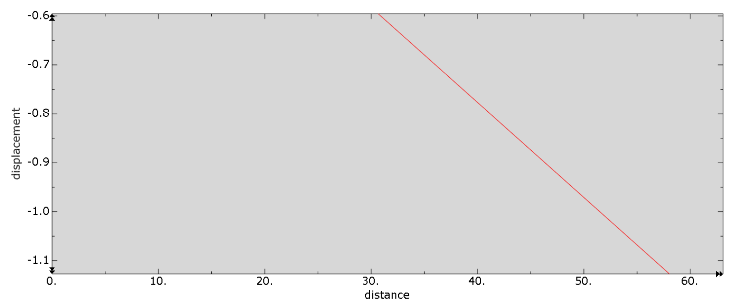

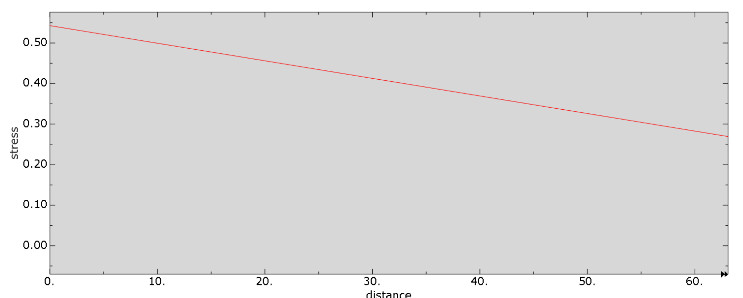

Taking the end of the tip of the mechanical arm as the middle axis and the length as the research object, the growth of the mechanical arm with the middle axis, the stress and the displacement of the point on the part of the spine are analyzed to obtain the distance-displacement map (Figure 6) and distance-stress (Figure 7) map, respectively. The result show that the displacement and stress are linearly related to the axial distance. At the same time, the minimum stress (+9.100e-06) and maximum stress (+3.719e+00) of the manipulator under the force state were found in Figure 5. Therefore, it can be concluded that the mechanical arm can achieve rigid and flexible transformation.

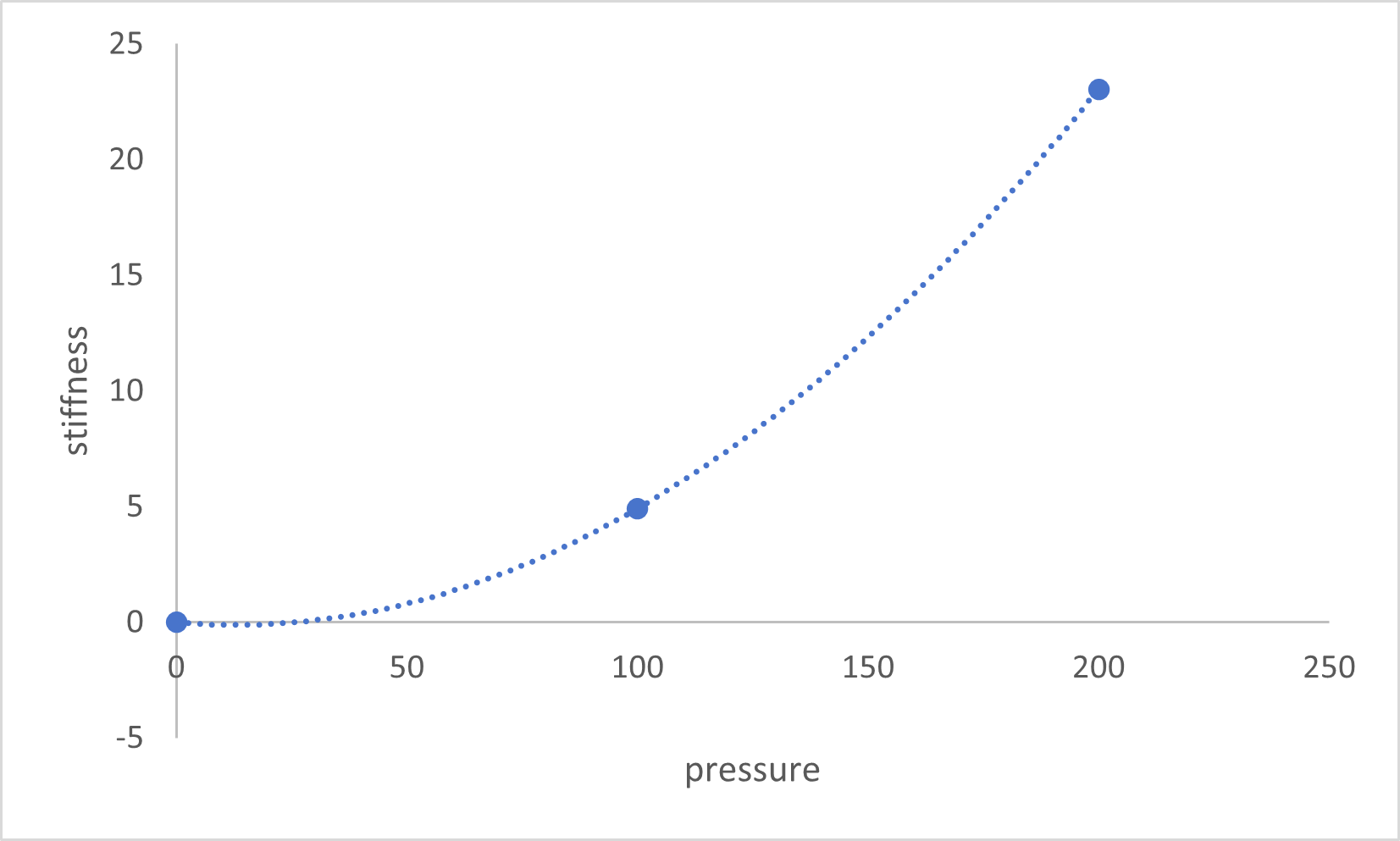

3.3.2. Pneumatic stiffness regulation effcicency

Before analysing the pneumatic stiffness adjustment efficiency part, it is necessary to conduct a stiffness test first.. In the simulation software, 0 kPa, 100 kPa, and 200 kPa were applied to the airbag groove, and it was assumed that the displacement of the reference point in the Y-direction of the robotic arm is 0 when 0 kPa is applied, meaning the stiffness of the robotic arm is 0 at this time. The simulation results were verified by measuring the displacement distance (

Subsequently, based on these results, the equivalent force

Where

Moreover, according to the design, the airbag groove is a cylinder with a base radius of 3.5 mm and a height of 15 mm. Taking a single section as an example for analysis, the pressure acting area is:

Substituting the known values, the equivalent forces under different pressures are obtained. The stiffness of the robotic arm is then calculated using the formula:

Thus, the equivalent stiffness values corresponding to different pressures are derived (Table 2), and the pressure-stiffness curve (Figure 8). Figure 8 shows that as the pressure increases, the stiffness of the robotic arm continuously increases. This demonstrates that variable stiffness control of the robotic arm can be achieved by adjusting the airbag pressure.

|

Pressure (kPa) |

Displacement (mm) |

Equivalent Force (N) |

Stiffness (N/mm) |

|

100 |

8.27 |

40.66 |

4.92 |

|

200 |

3.53 |

81.33 |

23.04 |

4. Discussion

In Static Bending and Stress Distribution Analysis, under a 100 N concentrated end load, the manipulator exhibited a linear correlation between axial displacement and Von Mises stress (

These results collectively validate the mechanical feasibility of the biomimetic design: the square geometry optimizes structural integrity under compression, while pneumatic actuation provides dynamic stiffness tuning without compromising deformability.

5. Conclusion

This paper addresses the inherent trade-off between flexibility and load-bearing capacity of conventional soft-bodied robots based on a square prismatic spine structure and modular segmentation of the seahorse tail. In this experiment, the mechanical properties of the bionic manipulator were systematically evaluated by means of multiphysics simulation. Static bending analysis shows that the modular joint design can effectively disperse the stress concentration. The air pressure adjustment experiment verified the significant influence of the biomimetic structure on the stiffness control. Experimental results demonstrate the mechanical feasibility of the bionic design of this paper, with the square geometry optimising structural integrity under compression, while allowing for dynamic adjustment of stiffness without compromising deformation capacity, providing superb flexibility.

Despite these advancements, two limitations remain unresolved, the first being the temperature-dependent material behavior, with the silicone spinal components exhibiting significant elastic modulus variation (

In response to the problems in this paper, integrated real-time thermal compensation mechanisms (e.g., embedded sensors or active cooling) can be added in the future to address the material temperature [8,10]. As well, embedding miniature temperature sensors (e.g., MEMS thermistors) within airbag cavities in concert with a feedforward control loop to dynamically adjust pressure to counteract modulus variations. For instance, a lookup table mapping

On this basis, future work would also prioritizes closed-loop control to bridge mechanical validation and environmental robustness, aligning with soft robotics roadmaps [11]. Algorithmic solutions offer scalable[1], platform-agnostic advantages over material-specific optimizations, as demonstrated in recent deep reinforcement learning approaches [12-14]

References

[1]. Rus, D. , & Tolley, M. T. "Design, Fabrication and Control of Soft Robots. " Nature, 2015, 521(7553), 467-475. DOI: 10. 1038/nature14543

[2]. Porter, M. M. , Adriaens, D. , Hatton, R. L. , Meyers, M. A. , & McKittrick, J. (2015). Why the seahorse tail is square. Science, 349(6243), aaa6683. DOI: 10. 1126/science. aaa668

[3]. Marchese, A. D. , Katzschmann, R. K. , & Rus, D. "A Recipe for Soft Fluidic Elastomer Robots. " Soft Robotics, 2015, 2(1), 7-25. DOI: 10. 1089/soro. 2014. 0022

[4]. Shepherd, R. F. , Ilievski, F. , Choi, W. , Morin, S. A. , Stokes, A. A. , & Whitesides, G. M. "Multigait Soft Robot. " Proceedings of the National Academy of Sciences, 2011, 108(51), 20400-20403. DOI: 10. 1073/pnas. 1116564108

[5]. Katzschmann, R. K. , DelPreto, J. , MacCurdy, R. , & Rus, D. "Exploration of Underwater Life with an Acoustically Controlled Soft Robotic Fish. " Science Robotics, 2018, 3(16), eaar3449. DOI: 10. 1126/scirobotics. aar3449

[6]. Laschi, C. , Mazzolai, B. , & Cianchetti, M. "Soft Robotics: Technologies and Systems Pushing the Boundaries of Robot Abilities. " Science Robotics, 2016, 1(1), eaah3690. DOI: 10. 1126/scirobotics. aah3690

[7]. Yap, H. K. , Ng, H. Y. , & Yeow, C. -H. "High-Force Soft Printable Pneumatics for Soft Robotic Applications. " Soft Robotics, 2016, 3(3), 144-158. DOI: 10. 1089/soro. 2016. 0030

[8]. Chang, J. C. , et al. "Development of a Continuum Robot with Inflatable Stiffness-Adjustable Elements for In-Situ Repair of Aeroengines. " *Robotics and Computer-Integrated Manufacturing*, vol. 95, 2025, p. 103018. DOI:10. 1016/j. rcim. 2025. 103018.

[9]. Polygerinos, P. , Wang, Z. , Galloway, K. C. , Wood, R. J. , & Walsh, C. J. "Soft Robotic Glove for Combined Assistance and at-Home Rehabilitation. "Robotics and Autonomous Systems, 2015, 73, 135-143. DOI: 10. 1016/j. robot. 2014. 08. 014

[10]. Thuruthel, T. G. , Shih, B. , Laschi, C. , & Tolley, M. T. "Soft Robot Perception Using Embedded Soft Sensors and Recurrent Neural Networks. " Science Robotics, 2019, 4(26), eaav1488. DOI: 10. 1126/scirobotics. aav1488

[11]. Bartlett, N. W. , Tolley, M. T. , Overvelde, J. T. B. , Weaver, J. C. , & Wood, R. J. "A 3D-Printed, Functionally Graded Soft Robot Powered by Combustion. " Science, 2015, 349(6244), 161-165. DOI: 10. 1126/science. aab0129

[12]. Joshi Kumar, V. , and Vinodh Kumar Elumalai. "A Proximal Policy Optimization Based Deep Reinforcement Learning Framework for Tracking Control of a Flexible Robotic Manipulator. " *Results in Engineering*, vol. 25, 2025, p. 104178. DOI:10. 1016/j. rineng. 2025. 104178.

[13]. Cianchetti, M. , Laschi, C. , Menciassi, A. , & Dario, P. "Biomedical Applications of Soft Robotics. " Nature Reviews Materials, 2018, 3(6), 143-153. DOI: 10. 1038/s41578-018-0022-y

[14]. Rus, D. , & Tolley, M. T. "Design, Fabrication and Control of Origami Robots. " Nature Reviews Materials, 2018, 3(6), 101-112. DOI: 10. 1038/s41578-018-0009-8

Cite this article

Ma,K.;Chen,K.;Liu,Q. (2025). A Hippocampus-like Robotic Arm Based on Controllable Airbag. Theoretical and Natural Science,122,1-11.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MPCS 2025 Symposium: Leveraging EVs and Machine Learning for Sustainable Energy Demand Management

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Rus, D. , & Tolley, M. T. "Design, Fabrication and Control of Soft Robots. " Nature, 2015, 521(7553), 467-475. DOI: 10. 1038/nature14543

[2]. Porter, M. M. , Adriaens, D. , Hatton, R. L. , Meyers, M. A. , & McKittrick, J. (2015). Why the seahorse tail is square. Science, 349(6243), aaa6683. DOI: 10. 1126/science. aaa668

[3]. Marchese, A. D. , Katzschmann, R. K. , & Rus, D. "A Recipe for Soft Fluidic Elastomer Robots. " Soft Robotics, 2015, 2(1), 7-25. DOI: 10. 1089/soro. 2014. 0022

[4]. Shepherd, R. F. , Ilievski, F. , Choi, W. , Morin, S. A. , Stokes, A. A. , & Whitesides, G. M. "Multigait Soft Robot. " Proceedings of the National Academy of Sciences, 2011, 108(51), 20400-20403. DOI: 10. 1073/pnas. 1116564108

[5]. Katzschmann, R. K. , DelPreto, J. , MacCurdy, R. , & Rus, D. "Exploration of Underwater Life with an Acoustically Controlled Soft Robotic Fish. " Science Robotics, 2018, 3(16), eaar3449. DOI: 10. 1126/scirobotics. aar3449

[6]. Laschi, C. , Mazzolai, B. , & Cianchetti, M. "Soft Robotics: Technologies and Systems Pushing the Boundaries of Robot Abilities. " Science Robotics, 2016, 1(1), eaah3690. DOI: 10. 1126/scirobotics. aah3690

[7]. Yap, H. K. , Ng, H. Y. , & Yeow, C. -H. "High-Force Soft Printable Pneumatics for Soft Robotic Applications. " Soft Robotics, 2016, 3(3), 144-158. DOI: 10. 1089/soro. 2016. 0030

[8]. Chang, J. C. , et al. "Development of a Continuum Robot with Inflatable Stiffness-Adjustable Elements for In-Situ Repair of Aeroengines. " *Robotics and Computer-Integrated Manufacturing*, vol. 95, 2025, p. 103018. DOI:10. 1016/j. rcim. 2025. 103018.

[9]. Polygerinos, P. , Wang, Z. , Galloway, K. C. , Wood, R. J. , & Walsh, C. J. "Soft Robotic Glove for Combined Assistance and at-Home Rehabilitation. "Robotics and Autonomous Systems, 2015, 73, 135-143. DOI: 10. 1016/j. robot. 2014. 08. 014

[10]. Thuruthel, T. G. , Shih, B. , Laschi, C. , & Tolley, M. T. "Soft Robot Perception Using Embedded Soft Sensors and Recurrent Neural Networks. " Science Robotics, 2019, 4(26), eaav1488. DOI: 10. 1126/scirobotics. aav1488

[11]. Bartlett, N. W. , Tolley, M. T. , Overvelde, J. T. B. , Weaver, J. C. , & Wood, R. J. "A 3D-Printed, Functionally Graded Soft Robot Powered by Combustion. " Science, 2015, 349(6244), 161-165. DOI: 10. 1126/science. aab0129

[12]. Joshi Kumar, V. , and Vinodh Kumar Elumalai. "A Proximal Policy Optimization Based Deep Reinforcement Learning Framework for Tracking Control of a Flexible Robotic Manipulator. " *Results in Engineering*, vol. 25, 2025, p. 104178. DOI:10. 1016/j. rineng. 2025. 104178.

[13]. Cianchetti, M. , Laschi, C. , Menciassi, A. , & Dario, P. "Biomedical Applications of Soft Robotics. " Nature Reviews Materials, 2018, 3(6), 143-153. DOI: 10. 1038/s41578-018-0022-y

[14]. Rus, D. , & Tolley, M. T. "Design, Fabrication and Control of Origami Robots. " Nature Reviews Materials, 2018, 3(6), 101-112. DOI: 10. 1038/s41578-018-0009-8