1. Introduction

Rocket propellant is mainly composed of fuel and oxidizer and other substances. Propellants are divided into solid propellants and liquid propellants. In addition to the two substances mentioned above, solid propellant contains additives and other substances. Among them, fuel and oxidant are the basic components, while additives are other components added in small amounts to improve combustion performance. The solid propellant is installed in the combustion chamber of the solid rocket motor, and after ignition, the solid propellant burns rapidly from bottom to top or from inside to outside. In the liquid rocket engine, the liquid propellant is generally pressurized by high pressure gas to fuel and oxidizer tank, and then the turbopump is used to further pressurize the fuel and oxidizer and transport them into the combustion chamber. The high temperature and high pressure gas formed by propellant combustion is ejected through the engine nozzle to generate thrust.

Liquid propellant can be subdivided into single component propellant and double component propellant. Single-component propellant refers to a component that is decomposed or burned through a catalyst to generate thrust, commonly used are hydrogen peroxide, hydrazine anhydrous, etc. The benefits of liquid propellant are its relatively high energy production, easy adjustment of thrust control, and the ability to repeatedly shut down and start again. Therefore, liquid propellants are widely used in launch vehicles for launching spacecraft.

At present, the most commonly used rocket fuel is chemical fuel, chemical fuel thrust is good, but not high mass efficiency and energy density. The Saturn V took astronauts to the moon, consuming

3,600 cubic meters of fuel and generating 35 million Newtons of thrust. The limitations of chemical fuels are obvious. To get farther, the rocket has to carry more fuel, and more fuel means more rocket weight [1].

This paper analyses the advantages and disadvantages of the current mainstream propellants. The main research methods are literature review, theoretical calculation and chart making. This paper may facilitate the later research queries and looking forward that the rocket propellant of the future may use nuclear power.

2. Characteristics analysis of current used fuel

2.1. Single-component liquid propellant

Single-component liquid propellant is also known as "monopropellant". "Single-component liquid rocket propellant" means that it has only one component. It does not need to supply oxidizer from the outside when burning, and it will decompose by itself or decompose first and then burn. It is mainly suitable for micro single component propellant liquid rocket engine, and has been widely used in ballistic missile multiple warhead missile and space vehicle attitude control, at the same time it can also be used as gas generator working medium.

2.2. Dual component liquid propellant

Dual component liquid propellant is also known as "dual propellant", "dual component liquid rocket propellant" is composed of two kinds of components into the engine combustion chamber, combustion agent and oxidizer, these two components are mixed in the combustion chamber of the liquid rocket engine, this propellant is also known as separately transported propellant. Because of its high energy, it is the most widely used propellant in liquid rocket propellants, commonly used are nitric acid/mixed amine, nitrogen tetroxide/hydrazine and liquid oxygen/liquid hydrogen. Solid rocket propellants consist of fuel and oxidizer that react chemically under certain conditions to release energy, thereby producing thrust [2].

2.3. Chemical heat sink of endothermic hydrocarbon fuels

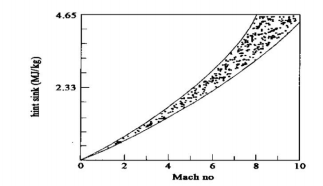

Fuel heat sink [2] is a core index to measure the heat absorption ability of fuel, which can quantitatively evaluate the performance of fuel as coolant, and its value is directly related to the flying velocity of aircraft. Figure 1 shows the requirements of fuel heat sink with the increase of flight Mach

number [3].

Figure 1. Heat sink against flight speed.

For Mach numbers greater than 5, one of the difficulties encountered by hypersonics is the high

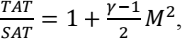

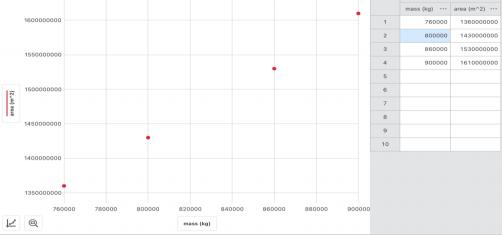

temperature problem caused by aerodynamic heating. According to the formula

where TAT represents true air temperature (°C), SAT represents static air temperature (°C), Y represents Gas specific heat capacity ratio (J°C/g), M represents Mach number, which can be concluded that if the plane flying in the stratosphere to hypersonic Mach number 6, the nose

temperature will rise to 1360 degrees Celsius, ballistic missiles or spacecraft with Mach number more than 10 speed into the atmosphere, the surface temperature of their heads can reach 4000 degrees Celsius. At this time, the fuel is required not only to have good combustion performance, but also to play the role of coolant [4].

Figure 2 shows the relationship between velocity and temperature more visually.

Figure 2. Graph generated by Desmos.

Endothermic hydrocarbon fuels have good thermal stability, and the physical heat absorption (physical heat sink) ability of fuels can be improved by increasing the thermal stability temperature of fuels. It is characterized by the use of its physical heat sink and chemical pyrolysis reaction heat absorption (chemical heat sink), which absorbs energy from the engine combustion chamber and tail nozzle, not only to cool the engine, but also to gasify the high-density fuel. For space aircraft, the dual-mode fuel formula [5] is proposed: when the flight speed is less than 8 Mach number, the endothermic hydrocarbon fuel is used. When the Mach number reaches 8, liquid hydrogen is used as fuel until the upper stage rocket reaches the separation speed.

Catalytic dehydrogenation is a kind of endothermic hydrocarbon fuel. The advantages of catalytic dehydrogenation are high conversion rate at lower temperature, large heat absorption reaction, single and stable product, and large amount of hydrogen production [6]. For example, assuming that all methylcyclohexane is converted into toluene and hydrogen by catalytic dehydrogenation [7], its chemical endothermic capacity is 2.19MJ/kg, and its total endothermic capacity is 4.56MJ/kg, which meets the heat sink flight required when the Mach number is 10. Catalytic pyrolysis of hydrocarbon fuels can greatly reduce the pyrolysis temperature, increase the conversion rate and selectivity of low carbon olefin, and significantly increase the chemical heat sink of fuel [8].

3. Comparison and analysis

3.1. Single-component liquid propellant

The obvious advantage of poly single-component liquid propellant is that it can simplify the propellant system of rocket engines and improve the reliability. However, its disadvantages of high explosion risk and low energy (specific impulse is about 170s) limit its application and development [9].

3.2. Dual component liquid propellant

The use of two-component propellant can significantly increase the possibility of selecting suitable substances as combustion agents and oxidants, and thus can create the most efficient propellant. However, common liquid propellants are also highly corrosive, flammable, explosive and toxic, which bring difficulties to transportation, storage and use and harm to human beings and the environment.

3.3. Endothermic hydrocarbon fuels

The catalyst can significantly improve the chemical heat sink of endothermic hydrocarbon fuels, but the catalyst is easy to deactivate and difficult to add, so it has some limitations in practical application.

4. Discussion

4.1. Possible solution

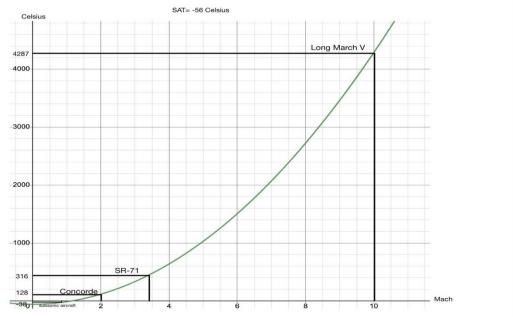

From the point of view of saving energy, solar power is a very good choice. Solar energy is an almost infinite source of energy, five times more mass efficient than chemical fuels. But how much thrust is

generated? According to the equations F =

and a =

, where P represents power (1400 watts/m2 ),

a represents the surface area of the solar panel (1 m2), c represents the speed of light (30,000km/s), and M represents the mass of the spacecraft (kg). Take the Long March V carrier rocket for example, it weighs 860 tons, To reach the third cosmic speed, F = Ma= 860000kg×16.7 km/s=1436200N, and

the area of the solar panel required is A =

= 1538785m2 . This is

obviously unrealistic, and even if you reduce the mass of the rocket, the area of the solar panels will still add significantly to the budget. Moreover, the solar energy comes from the star, the farther away from the star, the worse the actual effect, so this scheme has great limitations. Fig.3 shows the mass of

aircraft against area of solar panel required.

Figure 3. Graph generated by Vernier Graphical Analysis.

Another possible solution is nuclear power. Nuclear propulsion for space is the key to long-term high- payload missions. Compared with conventional hydrogen and oxygen chemical rockets, and rockets can provide more thrust, nuclear rockets use lighter molecular mass gas. Nuclear submarines use small fission reactors, which use the heat from the reactor to heat the gas and eject it for thrust. This can be used to propel rockets and provide steady thrust for long periods of time. Powered by a small nuclear fission reactor, a human rocket could save a quarter of its flight time, according to NASA simulations. Nuclear propulsion for space is the key to long-term high-payload missions. Compared with conventional hydrogen and oxygen chemical rockets, and rockets can provide more thrust, nuclear rockets use lighter molecular mass gas.

For space missions, nuclear-powered rockets should not be limited to "small nuclear fission reactors". Future space missions will be longer and longer. A "nuclear power system" should be installed on the rocket, which uses a high-power nuclear fission reactor to provide power for the rocket

while meeting its propulsion, just like traveling in space with a "nuclear power plant". Nuclear- powered rockets with a "nuclear power system" will have unlimited potential, and humans can install additional electric thruster on the spacecraft to further improve flight efficiency.

4.2. Future work

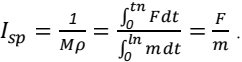

Future propellants should be developed towards nuclear power and high energy propellants. High- energy propellant generally refers to a class of propellants with high specific impulse. Specific impulse is a comprehensive measure of engine performance, denotedIsp , inN/(kg/s), and expressed as

It can be seen from the above equation that the greater the specific impulse of the engine, the less the propulsion dose needs to be consumed to produce the same thrust, that is, the greater the propellant energy, the greater the specific impulse of the engine [10].

The specific impulse of solid rocket motor can reach 2200~2500N/(kg/s); the specific impulse of the conventional propellant is 2500~3300 N/(kg/s), while the specific impulse of the high-energy propellant can reach 4500 N/(kg/s) or more. It can be seen that high-energy propellants mainly refer to high-energy propellants in liquid propellants, such as propellants containing O, H, Cl, B, F and other elements.

5. Conclusion

The heat sink of fuel can be improved based on existing science to improve flight safety. Although the use of modular liquid propellant can effectively simplify the propellant system of rockets, it is not satisfactory in terms of fuel efficiency and has certain risks. Binary liquid propellant is the most widely used propellant at present. It has high fuel efficiency, but it is not friendly to the environment, and brings certain difficulties to storage, transportation and use. In the future work, high energy and nuclear power engines should be the main object of development. While nuclear power can provide long-term stable endurance, it can also provide convenience for other aspects of spacecraft.

With the development of rocket science and technology and the improvement of performance, the technical requirements for rocket propellant are becoming higher and higher. From the above discussion, it can be concluded that the future propellant should mainly focus on nuclear power, high energy, so as to provide a long-term stable endurance for the rocket to provide reliable power guarantee.

References

[1]. Mohammed Alazeezi, Two Component Propellent Grain For Rocket Motor Combustion Analysis and Geometric Optimization [J] Thermal Science, vol.26, no.2B, 2022, pp. 1567-1578.

[2]. He Fang, Research progress on improving heat sink of hydrocarbon fuels [J] Progress in Chemistry, vol 18, no.7/8, 2006, pp. 1041-1043.

[3]. Zhu D. Y. Master Thesis of School of Chemical Engineering and Technology, Tianjin University, 2004.

[4]. Mahjub, A., et al., Design Optimization of Solid Rocket Propulsion: A Survey of Recent Advancements, Journal of Spacecraft and Rockets, vol.57, no.1, 2020, pp. 3-11.

[5]. Zhan Y. Maneuverable missile [J] Winged Missiles Journal, 3, 2003, pp. 43-49.

[6]. Sutton, G., Biblarz, O., Solid Propellant Rocket Motor Fundamentals, in: Rocket Propulsion Elements John Wiley and Sons Inc., New Jersey, USA, 2016, pp. 434-490.

[7]. R. Basso, S. Carbonin, and A. D. Giusta, J. Z. Kristallogr, vol.194, 1991, pp.111-119.

[8]. C. Griego, N. Yilmaz, and A. Atmanli, Analysis of aluminum particle combustion in a downward burning solid rocket propellant, Fuel, vol. 237, pp. 405–412, 2019.

[9]. E. Cohen. Combustion Characteristics of Advanced Netramine-Based Propellants, 18th Symposium (Int) on Combustion, 1981.

[10]. Li L, Preliminary study on Catalyst action Mode in High Energy propellant [D] Propulsion Technology, 1996.

Cite this article

Ma,J. (2023). Analysis of the characteristics of rocket propellant. Theoretical and Natural Science,5,490-495.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Computing Innovation and Applied Physics (CONF-CIAP 2023)

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Mohammed Alazeezi, Two Component Propellent Grain For Rocket Motor Combustion Analysis and Geometric Optimization [J] Thermal Science, vol.26, no.2B, 2022, pp. 1567-1578.

[2]. He Fang, Research progress on improving heat sink of hydrocarbon fuels [J] Progress in Chemistry, vol 18, no.7/8, 2006, pp. 1041-1043.

[3]. Zhu D. Y. Master Thesis of School of Chemical Engineering and Technology, Tianjin University, 2004.

[4]. Mahjub, A., et al., Design Optimization of Solid Rocket Propulsion: A Survey of Recent Advancements, Journal of Spacecraft and Rockets, vol.57, no.1, 2020, pp. 3-11.

[5]. Zhan Y. Maneuverable missile [J] Winged Missiles Journal, 3, 2003, pp. 43-49.

[6]. Sutton, G., Biblarz, O., Solid Propellant Rocket Motor Fundamentals, in: Rocket Propulsion Elements John Wiley and Sons Inc., New Jersey, USA, 2016, pp. 434-490.

[7]. R. Basso, S. Carbonin, and A. D. Giusta, J. Z. Kristallogr, vol.194, 1991, pp.111-119.

[8]. C. Griego, N. Yilmaz, and A. Atmanli, Analysis of aluminum particle combustion in a downward burning solid rocket propellant, Fuel, vol. 237, pp. 405–412, 2019.

[9]. E. Cohen. Combustion Characteristics of Advanced Netramine-Based Propellants, 18th Symposium (Int) on Combustion, 1981.

[10]. Li L, Preliminary study on Catalyst action Mode in High Energy propellant [D] Propulsion Technology, 1996.