1. Introduction

New energy automobiles are the development hotspot in China, as well as the electric hub automobiles. The characteristic of hub drive is that the power system is quite different from that of traditional electric automobiles, and the tram is driven by hub motors instead of the traditional power system. The replacement of the motor causes the unsprung mass of the suspension system to increase, which brings the problem of an extra high-frequency excitation source. Therefore, the hub motor may cause problems of aggravated vibration, poor automobile stability, and deteriorated handling stability. It is one of the methods to solve this problem of replacing traditional suspension systems with air suspension. Air suspension can adjust the height of the body with the change of road conditions, keep the best driving state, and adjust the height of the body according to the load situation, so as to provide better stability and smoothness. The advantages and disadvantages of air suspension compared with traditional mechanical suspension are analyzed, and the semi-active control of air suspension is discussed, which is of great significance to the application of air suspension.

2. Air suspension working scheme

Air suspension is located at the joint of the chassis and wheels, which can support, buffer, and attenuate vibration. The main difference between air suspension and traditional suspension is that the mechanical spring is replaced by an air spring, and the corresponding function is realized by the reaction force brought by the compression of air inside the air spring. Air suspension structure is generally by the use of airbags filled with air to play the role of rigid spring in the traditional suspension, and its elastic force is the reaction force generated when the internal air is compressed [1]. As a suspension system of automobiles, air suspension can transmit the force and moment between wheels and frame, buffer the impact force provided by road surface during driving, and attenuate vibration. When the force is applied between the wheels and body, the damping force or stiffness of the suspension system is adjusted accordingly, and it is controlled to effectively restrain the vibration of the body and reduce the vibration amplitude of the wheels. Nowadays, many high-end automobiles use air suspension as their system because it can freely change the chassis height, freely adjust the softness and hardness of shock absorption, and attenuate vibration, which makes run more smoothly and has excellent mechanical performance [2].

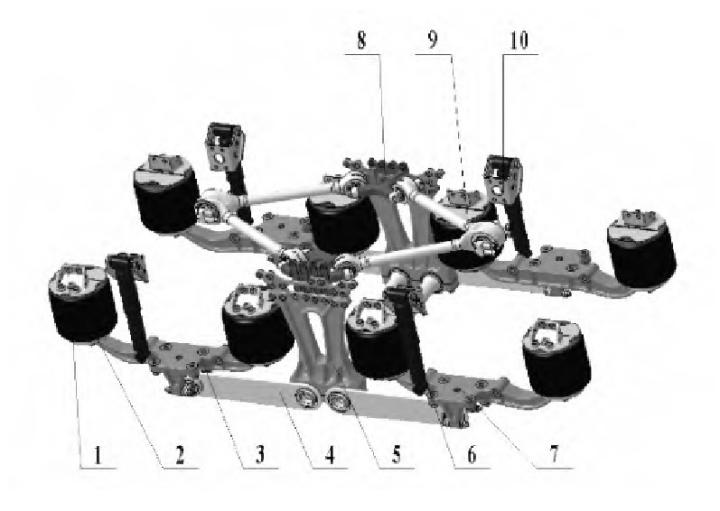

Figure 1. Air suspension structure scheme [3].

1—Airbag bracket; —Airbag; 3—left airbag lower bracket; 4—leaf spring assembly; 5—Coil spring bracket; 6—Vibration damper; 7—Right airbag lower support bracket; 8—V-shaped thrust rod bracket; 9—V-shaped thrust rod; 10—bracket

As shown in Figure. 1, the parts of the air suspension system are composed of brackets, adjusting bolts, valves, main air chambers, airbags, adjusting rods, adjusting valve spools, pistons, throttles and other devices [4]. As a suspension system, air spring is the core of air suspension system, which plays the role of spring through the compression of gas in suspension system. The compressor and air storage tank provide the possibility of changing the height and softness of shock absorption for the air suspension system. Generally, the height of the suspension system and the softness and hardness of shock absorption are input with relevant signals, and the actuator receives the relevant signals and then adjusts them accordingly, so as to realize the functions of changing the height and softness, and hardness of shock absorption. The air suspension system also includes sensors, valves, and other components. The existence of sensors ensures the full closed loop of the air suspension system and its precision.

Finally, this paper also makes a comparative analysis of the drive system layout of pure electric vehicles and traditional fuel vehicles, discusses the differences between the drive system of pure electric vehicles and traditional fuel vehicles, and finds that the optimized pure electric vehicle drive system has obvious advantages in lightweight and riding comfort. The optimal layout of the drive system and the optimization of the material and structure of the drive axle body will become two important directions in the optimization research of the drive axle of new energy vehicles.

3. The advantages and the disadvantage of air suspension compared to traditional suspension systems

3.1. The advantages of air suspension compared to traditional suspension systems

The air suspension system has the advantage of low vibration frequency and slow load variation, and the suspension stiffness can also be adjusted according to the gas quality of the air spring and the control system to adapt to different road surfaces. The non-linear stiffness characteristic of the air spring can be ideally designed according to actual needs, so that it has a lower stiffness value near the rated load, ensuring good driving smoothness of the vehicle [5]. One of the reasons why air suspension has research value is that it has good vibration damping compared to traditional suspension, which is determined by the physical properties of the gas in the air tank [6]. Therefore, to a certain extent, it avoids the fatigue fracture of mechanical spring suspension components; however, in reality, air springs also face problems such as bag deflation, wear, decreased elasticity, and damage to the upper cover plate or lower seat retaining ring, causing air leakage. Therefore, on the issue of a mechanical spring failure, air suspension only changes the problem rather than solves it. Due to the components of the electronic air pump, air distributor valve, inflation tube, height sensor, controller, and so on, the air suspension can have strong control. For example, air suspension can achieve chassis lifting function through a control system output signal, and air suspension can achieve active control through sensor detection of various indicators, which traditional mechanical spring suspension cannot achieve.

Firstly, the air suspension can adjust the height of the vehicle body and maintain a suitable height under heavy and light loads, ensuring the stability and safety of the vehicle. Mechanical spring suspension does not have the characteristics of adjusting the height of the vehicle body, and it cannot simultaneously adapt to heavy and light loads because it cannot change the total damping force or stiffness. In addition, air suspension can adjust shock absorption in real-time according to the road surface, providing a smoother driving experience and avoiding damage to the vehicle and passengers caused by vibration. Secondly, the air suspension can effectively protect the road surface and reduce road damage. For example, if a heavy truck equipped with mechanical spring suspension passes through a potholed road surface, the spring will rebound the vehicle body, producing a large force and impact on the road surface, causing damage; however, if air suspension is used, it can automatically adjust shock absorption according to the road surface condition, reducing the impact of force on the road surface and protecting the integrity of the road surface. In addition, because air suspension can be used to achieve load balancing, it can also reduce the pressure on the vehicle in heavy-duty vehicles, avoiding excessive damage to the road surface. Finally, air suspension can improve the riding experience and reduce the damage to the vehicle and passengers during driving. For example, using air suspension in heavy vehicles such as sightseeing buses and luxury coaches can provide a more comfortable riding experience, and prevent strong vibration and bumps during driving.

The air suspension is lightweight, has low spring stiffness, can improve tire adhesion and starting ability on low adhesion coefficient road surfaces at high speeds, and shorten braking distance [7]; during steering, the tendency of excessive or insufficient steering is reduced, steering stability is strong, and the handling stability of the entire vehicle is improved. Based on the working mode of air suspension, it has high precision, but it also means that the suspension is composed of a large number of necessary high-precision parts such as an electronic air pump, air distributor valve, various sensors, controllers, etc., which also means that its manufacturing complexity and requirements of manufacturing cost and maintenance cost are relatively high, resulting in the overall cost of air suspension which is far higher than that of mechanical spring suspension. This is one of the main reasons why air springs have not been popularized on ordinary cars. The current situation of air suspension parts manufacturing and research and development in China is inferior to that in foreign countries.

In terms of research, design, and manufacturing, overseas countries have established standards for design matching methods, calculation tools, prototype manufacturing, and testing in the field of air suspension. Components and systems have also formed product series and undergone years of optimization. However, there is still a gap in design, testing and validation conditions, and system reliability in domestic air suspension development [8]. In China, the development of electronic control air suspension systems (ECAS) is gradually being improved. A complete pneumatic control system mainly includes air supply devices, control components, actuating components, sensors, and the electronic control unit (ECU). In foreign countries, ECAS technology for passenger cars is already mature, while component technology is still being continuously improved. The integration of vehicle electronics control through system technology is also being constantly enhanced. Additionally, the commercial vehicle ECAS technology and market are also being explored. In mainland China, both components and system integration for automotive ECAS technology are still in the initial stages. Although technological progress will take time, the market prospects are still promising [8].

3.2. The disadvantage of air suspension compared to traditional suspension systems

The air spring has a complex structure and a high manufacturing cost of [5]. Compared to traditional springs, air springs offer higher flexibility, making them widely used in modern automobiles. However, due to their complex structure, manufacturing air springs can be relatively expensive. Air springs require additional airbags and compressors to provide the appropriate air pressure, increasing both manufacturing and maintenance costs. Moreover, air springs are typically made from special materials with high strength and lightweight properties, such as rubber and polyurethane, further adding to the manufacturing costs. In practical use, air springs require frequent maintenance and replacement, resulting in higher initial installation, maintenance, and repair expenses for users. Therefore, comprehensive cost analysis is necessary for the design and manufacturing of air springs. To achieve the advantages of air springs while reducing manufacturing costs, designers must select suitable materials and structures based on actual conditions. Additionally, other techniques such as mechatronics integration, manufacturing process automation, and virtual manufacturing can be combined to reduce manufacturing costs and enhance the quality and efficiency of air springs.

The air suspension systems tend to have sealing difficulties. Air suspension systems have multiple sealing components, and poor sealing can directly affect the performance of the suspension [7]. The presence of numerous sealing components in air suspension systems means that even minor sealing issues can result in gas leakage, thereby affecting the performance of the suspension. The reasons for poor sealing can include aging of sealing materials, frictional wear, improper installation, and insufficient precision. Several practical examples have shown that sealing issues have significantly impacted the effectiveness of air suspensions. For instance, certain low-quality air springs can experience deformation and aging of the sealing rings over prolonged use, leading to air leakage and a decrease in suspension performance. Similarly, some vehicle owners may damage the sealing components due to rough handling during disassembly or incorrect installation sequence and precision, resulting in air leaks. Therefore, during the use of air suspensions, particularly when a decline in suspension performance is observed, it is important to promptly inspect the sealing components for timely repairs or replacements. Additionally, in terms of suspension sealing, accurate knowledge of sealing materials and manufacturing processes is essential, along with the application of new technologies to enhance sealing performance and reduce the deformation and aging rate of components. Overall, in the design and manufacturing process of air suspensions, it is crucial to prioritize sealing issues and ensure the sealing effectiveness and lifespan of the suspension, thereby enhancing reliability, stability, and driving experience.

4. Application of the air suspension

4.1. Air suspension applications in small cars

Air suspension is often used in the modified market in small cars to improve the off-road performance, improve the road adaptability and other effects. Specifically, the air suspension can be applied in the following models:

1. Audi A7: Audi A7 is a high-end model with factory air suspension. The modification of the air suspension can provide the owners with a smoother driving experience and higher travel stability and other advantages.

2.Mercedes-Benz C-Class: Mercedes C-Class C-Class are also high-end models. The application of air suspension can make the suspension system softer and make up for the uneven road surface.

3.The BMW 320i: The BMW 320i is a very cost-effective model. For such models, through the application of air suspension, the vehicle can walk more smoothly, reduce the impact of road vibration on the passengers in the car, but also to improve the vehicle's handling performance and road sense.

4.Tesla Model: Both Tesla Model S and Model X use air suspension system, with adjustable height air spring and pressure sensor on the suspension, which can adjust the height and hardness of the body in real time according to road conditions and driving mode, improving the vehicle's handling performance and ride comfort. Specifically, the system can be controlled by the LCD screen in the car or the mobile phone APP, and users can choose different height modes, including standard mode, low speed mode, lift mode, etc. Under different road conditions, if the user needs higher ground clearance (such as traffic obstacles by leveling the road surface), the user can raise the car body in "lift mode", while at high speeds, "low speed mode" can be selected to reduce wind resistance and improve stability. Overall, the air suspension system provides the Tesla Model S and Model X with more flexible and diverse suspension Settings, helping drivers maintain comfort and safety in a wide variety of road conditions.

4.2. Air suspension in large passenger cars, heavy vehicles, as well as agricultural vehicles applications

Air suspension has been widely used in large vehicles abroad [9], examples of air suspension applications in large buses as demonstrated as below:

Tourist buses: Due to their varied routes, which often involve rugged mountain roads or steep slopes, air suspension can provide passengers with a higher level of comfort during long journeys and reduce discomfort caused by bumps. Additionally, the complex road conditions encountered during bus travel can be better managed with air suspension, allowing the vehicle to adapt to various road surfaces. City buses: In dense urban traffic with complex road conditions, the use of air suspension can reduce vibrations and provide a smoother ride for passengers, enhancing both safety and comfort. Examples of air suspension applications in heavy-duty vehicles: 1. Trucks: Trucks encounter different cargo weights and driving conditions, often with severe longitudinal vibrations. Air suspension can adjust the vehicle's height, stabilize the body, increase load-carrying capacity, and reduce wear on the road, particularly when carrying heavy loads. 2. Trailers: Trailers transport a variety of goods, and air suspension can help adjust the lateral forces to prevent cargo slippage during transportation. With an adjustable suspension system, it can also recover bending forces generated during prolonged cornering, ensuring vehicle stability. Agricultural vehicles: 1. Tractors: Agricultural vehicles, during fieldwork and driving on uneven terrain or slopes, benefit from air suspension by enhancing adaptability to irregular road surfaces and improving stability and comfort. 2. Transport vehicles: Rural transport vehicles often navigate poor road conditions. The use of air suspension increases the vehicle's ability to adapt to irregular road surfaces, maintaining stable driving even under increased pressure. This improves safety, reduces maintenance costs, and minimizes the risk of damage. Please note that the translations provided are a human-generated approximation, and there may be slight variations in sentence structure and wording to ensure natural flow in English.

5. Development and prospect of the air suspension system

5.1. Development and prospect of air suspension system

Currently, in the field of automotive suspension systems in China, apart from the well-developed design and application of steel plate spring suspensions, the application of other suspension technologies mostly remains at the stage of vehicle introduction, imitation, or direct purchase of products. In July 2002, the Ministry of Transport's "Classification and Grading Evaluation of Operation Type Passenger Vehicles" stipulated that high-end medium, and large-sized passenger vehicles must adopt air suspensions [5]. This indicates the increasingly widespread use of air suspensions. In the domestic market, with the continuous expansion of the mid-to-high-end car market, the application of air suspensions will become more and more extensive. For example, imported vehicles such as Mercedes-Benz and BMW widely utilize air suspension technology in the domestic market, and domestic automobile companies have also started to introduce models equipped with air suspensions. For instance, the Geely Icon launched in 2021 uses a newly developed intelligent air suspension by Zotye, which enhances its ride comfort and driving stability. In the global market, more car manufacturers will introduce models equipped with air suspension technology. For example, Tesla, the American company, launched the all-new Model S and Model X models in 2022, which provide a smoother driving experience through air suspension technology and can automatically adjust the vehicle's height under different road conditions. Additionally, car manufacturers like Land Rover from the UK and Audi from Germany are actively promoting the application of air suspension technology in their models. In conclusion, air suspension technology will be widely applied in China and globally, becoming an important development direction in the automotive manufacturing industry.

5.2. Outlook for the air suspension system

In terms of development, design, and manufacturing, foreign countries have established standards in design matching methods, computational tools, prototype manufacturing, and testing. They have also optimized components and systems over the years, forming product series. However, there is still a gap in design, testing and verification conditions, and system reliability in the domestic air suspension development [8]. In the development of electronic controlled air suspension systems (ECAS), progress is gradually being made domestically. A complete pneumatic control system mainly includes an air source device, control components, actuation components, sensors, and an electronic control unit (ECU). In foreign countries, ECAS technology for passenger vehicles is already mature, while component technology continues to improve, and the integration of vehicle electronic control into the system is also being enhanced. The ECAS technology and market for commercial vehicles are also being explored. On the other hand, ECAS technology in mainland China, whether in terms of components or system integration, is still in its early stages. While technological advancements will require time, the market prospects for ECAS in mainland China are promising [8]. The air suspension system for trains can be mainly categorized into passive and active suspensions, with the active suspension further divided into semi-active and fully active suspension. Passive air suspension systems, due to their passive adjustment nature, cannot timely and appropriately respond to large-scale variations in vehicle speed and road conditions. They lack the ability to adaptive adjust the suspension's stiffness and damping, thus failing to achieve ideal performance. On the other hand, although fully active electronically controlled air suspension systems can provide timely and appropriate feedback to corresponding changes, they consume more energy and have complex system compositions, leading to energy wastage and susceptibility to signal interference, thereby increasing the instability factors in the system [10]. Therefore, this paper mainly focuses on semi-active air suspension. Semi-active air suspension, also known as semi-active or semi-passive suspension, can adjust in real-time according to different road conditions, altering the stiffness characteristics and damping of the suspension to adapt to various conditions [11]. Furthermore, air suspension can intelligently improve its characteristics by analyzing the vehicle's operating state, vibration characteristics, external excitation, etc., to achieve changes in vehicle performance and enhance driving comfort [12]. Therefore, semi-active air suspension exhibits strong adaptability to different driving environments and relatively lower costs. If the cost and maintenance issues can be addressed, popularizing semi-active air suspension in regular trains could be one of the solutions to mitigate the discomfort caused by train vibrations. Future trends and potential challenges: Artificial intelligence (AI) is a current development trend, and introducing advanced AI into various automated systems will make them more intelligent and enhance their performance accordingly. The continuous improvement of technology in the future will bring about significant changes to the automotive industry [12]. As a developing trend, AI technology has attracted considerable attention and has been widely applied in various fields such as construction, transportation, and daily life. Applying AI technology in the automotive driving domain can bring convenience, increase travel comfort, and effectively reduce the occurrence of traffic accidents [13]. In the case of the semi-active air suspension system discussed in this paper, incorporating AI control can achieve more intelligent and precise adjustments. For example, determining favorable solutions for driving comfort in special situations, bringing the performance of the air suspension system closer to the ideal. As air spring suspension becomes widely used in automobiles and the level of intelligence in automotive control systems continues to rise, the future development trend of air spring suspension lies in electronic controlled air spring suspension.

6. Conclusion

Air suspension is a suspension system that replaces traditional steel springs with gas springs. It offers excellent ride comfort and stability, allowing for adjustable vehicle height by controlling air pressure. This system enhances vehicle performance in terms of maneuverability, fuel efficiency, and off-road capability. However, air suspension entails higher maintenance and repair costs, requiring specialized technical expertise and equipment. Additionally, the utilization of electronic components such as sensors and electronic control units adds complexity and potential failure points to the suspension system. Air suspension surpasses traditional mechanical spring suspension in various aspects, including damping ability and adaptability to different environments. Its irreplaceable advantages lie in its active control and the ability to adjust suspension behavior through algorithmic control.

Authors contribution

All the authors contributed equally and their names were listed in alphabetical order.

References

[1]. Yu Z S. 2015 Automobile Theory. 5th Edition. Translated by Machinery Industry Press.

[2]. Xie Z C, Wang H, Wang B J, et al. 2023 Machinery Design and Manufacture, No.386(04):26-33.

[3]. Shen G W, Chen L Q, An K, et al. 2022 Automotive Practical, Technology, 47(21):91-96.

[4]. Fu S, Xu Y H, Sun Z B. 2023 Hydraulics & Pneumatics, 47(04): 107-114.

[5]. Tao J Z. 2005 Journal of Nantong Maritime College (04): 43-46.

[6]. Yu F, Yan Y, Wu X J. 2017 Bus Technology, (06): 46-47+50.

[7]. Wang W, Zhong Y M 2913 Automotive Practical Technology, (11): 97-101.

[8]. Wang W L, Hou Z C, Zou J. 2018 Journal of Automotive Safety and Energy, 9(01): 11-24

[9]. Cao X C, Zhao J G, Wang W Q. 2022 Construction Machinery Technology and Management, 35(06): 77-79.

[10]. Zhang D 2012 Development and Simulation Research of Automotive Air Suspension Electronic Control System. Northeast University, 2012

[11]. Lü Z P, Bi F G, Xu W, et al. 2021 Journal of Vibration and Shock, 40(2): 265-271.

[12]. Xu M, Huang Q S, Li G. 2021 Machine Tool & Hydraulics, 49(1): 169-174.

[13]. Li C B. 2023 Agricultural Development and Equipment, (01): 125-127.

Cite this article

Cheng,L.;Kang,Z.;Zeng,J. (2023). Analysis of the application of the air suspension system of pure electric vehicle. Theoretical and Natural Science,12,18-24.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mathematical Physics and Computational Simulation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yu Z S. 2015 Automobile Theory. 5th Edition. Translated by Machinery Industry Press.

[2]. Xie Z C, Wang H, Wang B J, et al. 2023 Machinery Design and Manufacture, No.386(04):26-33.

[3]. Shen G W, Chen L Q, An K, et al. 2022 Automotive Practical, Technology, 47(21):91-96.

[4]. Fu S, Xu Y H, Sun Z B. 2023 Hydraulics & Pneumatics, 47(04): 107-114.

[5]. Tao J Z. 2005 Journal of Nantong Maritime College (04): 43-46.

[6]. Yu F, Yan Y, Wu X J. 2017 Bus Technology, (06): 46-47+50.

[7]. Wang W, Zhong Y M 2913 Automotive Practical Technology, (11): 97-101.

[8]. Wang W L, Hou Z C, Zou J. 2018 Journal of Automotive Safety and Energy, 9(01): 11-24

[9]. Cao X C, Zhao J G, Wang W Q. 2022 Construction Machinery Technology and Management, 35(06): 77-79.

[10]. Zhang D 2012 Development and Simulation Research of Automotive Air Suspension Electronic Control System. Northeast University, 2012

[11]. Lü Z P, Bi F G, Xu W, et al. 2021 Journal of Vibration and Shock, 40(2): 265-271.

[12]. Xu M, Huang Q S, Li G. 2021 Machine Tool & Hydraulics, 49(1): 169-174.

[13]. Li C B. 2023 Agricultural Development and Equipment, (01): 125-127.