1. Introduction

Managing operations requires careful consideration and execution of a company's production system [1]. Efficiently managing resources such as raw materials, equipment, and human resources is crucial for the smooth functioning of the production system. The main goals of operations management involve enhancing efficiency, optimizing effectiveness, and strategically aligning the activities of the organization [1]. Fast fashion is a speedy and budget-friendly method of creating and manufacturing clothing, which has significant implications for the field of operations management.

Next plc, a well-known retail company, is based in Brighton, England. As an operations manager, it is crucial to strategically position a well-known company known for its wide range of clothing and home products in Brighton. The goal is to create a fashion-forward establishment that appeals to customers who are highly attuned to the latest trends. Next plc is well-known for its extensive range of shoes, clothing, and household items. Additionally, it employs a forward-thinking approach to stay competitive in the retail industry, curating a diverse selection of fashionable clothing and accessories. The company has strategically positioned itself to attract a wide range of clients by seamlessly blending complexity and user-friendliness. Next is dedicated to enhancing customer experience through its omnichannel strategy, which seamlessly integrates its physical stores and robust online presence [2]. The brand is a go-to for fashion-forward individuals in Brighton and beyond, who are always on the lookout for the latest styles. Ensuring the company remains up-to-date with fashion trends and consistently producing high-quality items helps to solidify the brand's position in the fiercely competitive retail industry.

In regards to the recent progress in research within this field, there is a journal article titled "Operations and Project Management Fast-Fashion Zara" that offers a comprehensive discussion on the decision areas of operational management in Zara [3]. The writers thoroughly evaluate the three primary aspects of design, sourcing, and distribution. According to certain arguments, Zara, H&M, and Topshop have successfully optimized their operations in the clothes retail industry. The authors employ game theory models to analyze the strategic interactions among merchants. They caution that frequent changes in product collections could potentially trigger competition and even product wars, resulting in increased costs for all parties involved without necessarily boosting their market share [3]. The journal article titled "It's Time for a New Model for Operations Management" delves into the importance of embracing a new perspective on operations management in response to the ever-changing supply and demand dynamics of the post-pandemic era [4]. The traditional approach to operations management is no longer sufficient in today's fast-paced and unpredictable business environment. The article proposes a new framework based on four key principles: trust, talent, transparency, and technology. Through the delegation of decision-making authority to the most suitable sources, this model allows for faster and more accurate responses to changing circumstances [4].

This study focuses on analyzing and reviewing the operational management of Next plc, with a particular emphasis on the fashion brand. This study examines the management of a fashion brand in the business sector, along with exploring innovative strategies for achieving long-term growth. These strategies could provide valuable insights for companies and brands in today's digital age. One example of this approach utilizes RFID (Radio-Frequency Identification) technology. RFID technology offers a range of advantages for a brand's operational management, such as improved inventory control, personalized marketing, and heightened consumer satisfaction.

2. Analysis of the various processes of the Next

2.1. Overview of Processes

Key components of Next's retail systems include product selection, inventory management, customer service, and transaction processing. Ensuring a seamless and delightful experience for customers is the top priority of the company. The enhanced operational efficiency of Next's website optimizes order processing and delivery processes. Our top priority is ensuring that every customer has a smooth and delightful shopping experience, regardless of whether they choose to shop in-store or online. Utilizing integrated techniques can help achieve this objective. The decision made by Next to integrate its online and retail operations demonstrates the company's commitment to catering to diverse customer preferences in a streamlined and efficient manner, ultimately enhancing operational effectiveness.

2.2. 4Vs Analysis

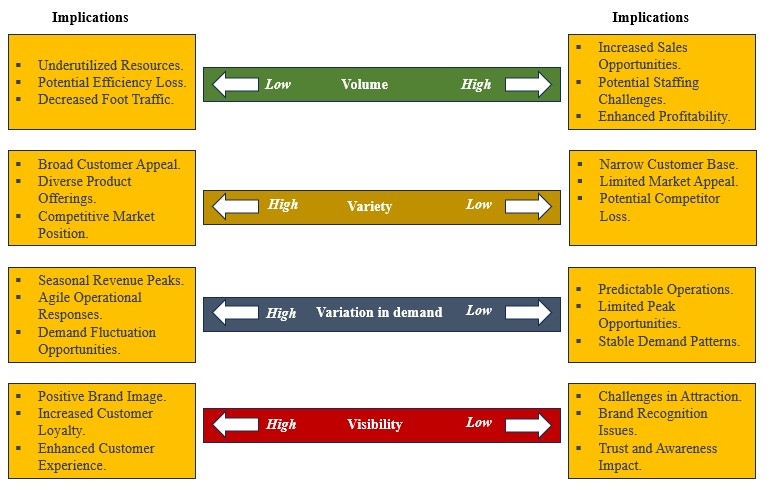

Variation, visibility, volume, and variety are evaluated using the 4Vs model [5]. As depicted in the figure 1 below, the retail operations of Next illustrate these dimensions.

Figure 1: 4Vs Strategy [6]

First in terms of Volume, Next attracts significant physical and virtual customer traffic, especially during heightened demand for products or services, such as the holiday season and promotional sales events [7]. This is particularly the case during periods of peak demand for purchases. Creating effective strategies to handle crowds and provide a pleasant shopping experience for clients is crucial in physical retail settings. Physical stores receive a large amount of foot traffic, which makes it crucial to establish effective procedures. The company's ability to effectively handle a large number of online orders demonstrates its strong market position and continued dedication to engaging with clients.

As for Variety, consisting of apparel, footwear, and domestic goods for men, women, and children, Next offers an extensive range of products. Additionally, Next provides merchandise for the domestic sphere. Dynamic and perpetually shifting inventory is ensured due to the organization's rapid adaptation to shifting fashion patterns. The compilation comprises a variety of tangible and digital assets, thereby augmenting the customer's overall sense of contentment [8]. The wide range of products is designed to cater to a diverse range of client preferences, aligning with the brand's image and Next's reputation for being fashion-forward. Proficient inventory management, merchandising tactics, and an efficient supply chain are essential for managing the vast range of products in the fashion sector.

With respect to variation, significant correlations exist among promotional activity, seasonal fluctuations, events, and Next's product demand. The company encounters fluctuations in consumer footfall and buying behaviors. Fluctuations are influenced by both seasonal elements and the efficiency of marketing strategies. For example, there is a noticeable increase in the desire for winter apparel when the temperature lowers, and sales occasions appeal to a specific group of consumers inclined to engage in transactions [8].

When it comes to visibility, it prioritizes customer-centricity and maintains a strong presence both in-store and worldwide [9]. Through effective strategies, eye-catching displays, and attentive staff, it is possible to create a positive and memorable customer experience at physical retail stores. Next is committed to providing its customers with a seamless and enjoyable experience. Due to a strong commitment, the company has prioritized visibility to ensure a positive experience. By implementing transparent and customer-focused business processes, the company can establish trust and confidence among its diverse clients.

2.3. Operations Hierarchy

Next store operations include sales and customer service. These operations strive to ensure customers have a positive in-store shopping experience by promoting active customer participation. These responsibilities include overseeing store-specific tasks like customer service, inventory management, and transaction facilitation. Administrative duties at the headquarters involve maintaining facilities, monitoring stock, and controlling online operations. Emphasis is placed on strategic decision-making in order to ensure the coordination and efficiency of the supply chain, timely acquisition of inventories, and effective management of digital platforms. The interconnected hierarchical procedures improve the efficiency and effectiveness of Next's retail operations.

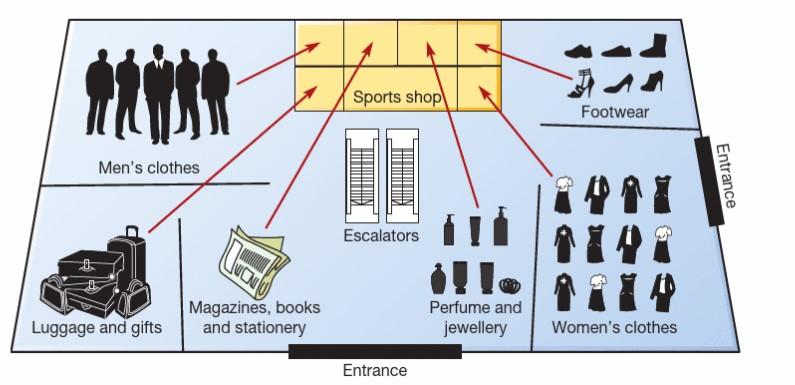

3. Description of layout

Following attractive clothing sections allow customers to browse different fashion categories in an organized manner. The organization uses a cell pattern to organize related products and improve the purchase experience for accessories. The purchase section intentionally uses a line layout to streamline the payment procedure for clients. The design indicated above improves the effectiveness and movement of the in-store experience by optimizing flow (Refer to Figure 2 for details).

Figure 2: Cell Layout at Next [6]

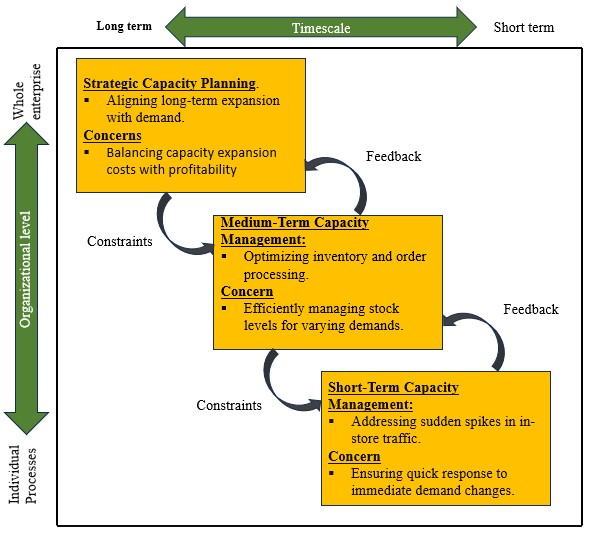

4. Description of capacity management

Capacity management, intermediate-term strategic planning, instant reactivity, and long-term strategic planning are all crucial components of this dynamic process. The store ensures consistency in its online and offline operations through a hybrid approach that combines pursuit and level capacity strategies. Efficiently gauging demand levels and effectively managing inventories to account for seasonal fluctuations are key priorities. Staff with the ability to quickly adapt and monitor situations in real-time are crucial for effectively addressing immediate needs and making necessary short-term adjustments. Figure 3 demonstrates the significance of the relationship in ensuring customer satisfaction and optimizing resource allocation. By adopting a comprehensive approach, we can navigate challenges and ensure optimal performance in various retail environments.

Figure 3: Capacity Management Integrated across levels [6]

First, Capacity Forms Used; Next seems to be implementing both the level and chase capacity plans. Next uses capacity management at its stores to supervise its personnel [10]. Next can guarantee effective customer service and operational competence at all times due to its efficient people. Next seems to employ a chasing capacity strategy on their internet platform to handle online order fulfillment. Second, Variation in Demand; Next uses capacity in tandem with fluctuations in demand. Promotional events throughout weekends often lead to more demand during that time. These activities enhance consumer engagement. Next experiences a notable surge in product demand when advertising campaigns are launched, resulting in an influx of customers to the store [10].

Third, Resource Availability; It was evident that Next adjusts its resources to align with swings in demand. For instance, Next augmented the staff on the floor in response to a substantial surge in demand to enhance customer service. Fourth, Cost Implications; Demand affects financial capacity management. Labor expenses have risen due to brick-and-mortar merchants expanding their workforce to meet client needs [11]. Despite being practical and effective, this investment poses financial difficulties. Profitability requires effectively managing labor expenses and utilizing resources efficiently. Workload estimate and scheduling are optimized to reduce costs, improve customer happiness, and better resource allocation. All benefits can be acquired at the same time.

5. Description of continuous and radical improvement

Next's retail branch offers clients a diverse selection of alternatives to make both substantial and gradual modifications to their products. The potential for increased customer satisfaction exists due to the implementation of enhanced transaction procedures designed to reduce waiting times and its contribution to the growth and development of the organization. Many prospective approaches could be adopted to streamline the processes entailed in the payment transaction. Some of these strategies include introducing self-service transaction choices, strategically deploying staff at peak times, and using efficient point-of-sale systems.

Then, it could investigate the possibility of integrating state-of-the-art technology into its inventory management system to effect significant change. This would constitute a strategy for implementing substantial modifications. Implementing RFID (Radio-Frequency Identification) technology to monitor inventory in real time can significantly influence the transformation of the supply chain [12]. This effect could potentially result from the implementation of RFID technologies. This technological development effectively mitigates the frequency of stockouts and surpluses by providing the capability for precise and delayed inventory monitoring [12]. This is achievable due to its capability for precise and postponed inventory surveillance. Potentially, the subsequent course of action would involve integrating state-of-the-art technologies into the inventory management system, aiming to enhance the company's operational efficiency.

Through the application of lean management principles, the organization can identify and eradicate inefficiencies within the various processes comprising its supply chain [13]. The organization's refuse detection system facilitates this capability. One potential focus for waste reduction actions is enhancing communication systems inside the supply chain network. Additional potential domains of emphasis encompass the streamlining of transportation routes and the eradication of surplus inventory. Following the implementation of lean principles, Next can enhance its operational efficiency, reduce the expenses linked to superfluous procedures, and improve its ability to adapt to changing market demands.

The objective is to enhance client contentment while concurrently streamlining business operations after implementing the suggested enhancements at Next. The organization intends to implement lean management principles whenever possible, reduce the number of transaction procedures, and utilize cutting-edge technologies for inventory management to enhance its supply chain's responsiveness and efficiency. The aim of continuous development is expanded to encompass the ongoing enhancement of processes. These initiatives are consistent with the overarching goal as they demonstrate a dedication to enhancing processes to maintain operational excellence. The main objective of these alterations is to create a procuring environment that guarantees a flawless and satisfying customer experience, the most effective utilization of the organization's resources, and the most significant cost benefit.

6. Conclusion

The generated models offer valuable insights into various aspects and are in line with Next's retail operations. Dealing with demanding situations can be tricky, as we strive to find the right balance between managing costs and providing exceptional customer service. Exploring the trade-offs between customer satisfaction and operational efficiency uncovers the intricate connection between these two factors. Although the observational method provides valuable insights into front-end activity, it has its limitations when it comes to revealing specific details about back-end procedures. Employee interviews and interactions were restricted due to ethical considerations to prevent any tampering with components. While the observations are limited, they provide a solid basis for future research. Implementing real-time inventory monitoring could greatly enhance operations by significantly improving velocity and accuracy. Efficient resource allocation can be enhanced through the use of technology to optimize scheduling in order to adapt to fluctuating demand. These suggestions tackle the mentioned challenges and help in developing a streamlined and successful operating strategy.

Maintaining a balance between customer service and profits requires ongoing monitoring. Before implementing new technology, it is crucial to evaluate its limitations and impact on the organization. A comprehensive evaluation necessitates a deep understanding of the retail industry, future forecasts, and customer preferences. To achieve success, it is crucial to have a flexible operational plan that can effectively adapt to market fluctuations and ensure a positive experience for clients.

References

[1]. Ivanov, D., Tsipoulanidis, A. & Schönberger, J. (2017). Basics of supply chain and operations management. In Global Supply Chain and Operations Management (pp.1-14). Springer Cham.

[2]. Cabigiosu, A. (2020). The ominichannel strategy in the fashion industry. In Digitalization in the Luxury Fashion Industry (pp.71-101).

[3]. Ajmi, N. M. A. (2020). Operations and project management fast-fashion Zara. Economic Geography, 17(2), 187-201.

[4]. Batato, M., Mesnard, X. & Gandhi, S. (2023). It’s time for a new model for operations management. Harvard Business Review.

[5]. Jia, Y. (2013). Manufacturing excellence: Operations management. Management Science and Engineering, 7(3), 111-117.

[6]. Slack, N. and Brandon-Jones, A. (2019) Operations Management. Pearson Education, Limited.

[7]. McKinsey & Company (2021). The state of fashion 2022. [Online]. Available at: https://www.mckinsey.com/~/media/mckinsey/industries/retail/our%20insights/state%20of%20fashion/2022/the-state-of-fashion-2022.pdf

[8]. Lemon, K. N. & Verhoef, P. C. (2016). Understating customer experience throughout the customer journey. Sage Journals, 80(6).

[9]. Hinsliff, G. (August 17, 2021). Whatever Next? How a middle-of-the-road high-street chain became a retail powerhouse. The Guardian.

[10]. Wright, G. (September, 2021). How Next, which was founded in Leeds, became one of the most reliable forces in retail. The Yorkshire Post.

[11]. Fisher, M., Gallino, S. & Netessine, S. (2019). Retailers are squandering their most potent weapons. Harvard Business Review.

[12]. Lee, Y. M., Cheng, F. & Leung, Y. T. (2005). Exploring the impact of RFID on supply chain dynamics. Proceedings – Winter Simulation Conference, 2, 1145-1152.

[13]. Solaimani, S., der Veen, J. A. A. V., Sobek II, D. K. & Gulyaz, E. (2019). On the application of lean principles and practices to innovation management: A systematic review. The TQM Journal.

Cite this article

Wang,J. (2024). Portfolio of Four Pieces of Analysis Using Operations Management Concepts—Taking Next as an Example. Advances in Economics, Management and Political Sciences,84,126-132.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Management Research and Economic Development

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ivanov, D., Tsipoulanidis, A. & Schönberger, J. (2017). Basics of supply chain and operations management. In Global Supply Chain and Operations Management (pp.1-14). Springer Cham.

[2]. Cabigiosu, A. (2020). The ominichannel strategy in the fashion industry. In Digitalization in the Luxury Fashion Industry (pp.71-101).

[3]. Ajmi, N. M. A. (2020). Operations and project management fast-fashion Zara. Economic Geography, 17(2), 187-201.

[4]. Batato, M., Mesnard, X. & Gandhi, S. (2023). It’s time for a new model for operations management. Harvard Business Review.

[5]. Jia, Y. (2013). Manufacturing excellence: Operations management. Management Science and Engineering, 7(3), 111-117.

[6]. Slack, N. and Brandon-Jones, A. (2019) Operations Management. Pearson Education, Limited.

[7]. McKinsey & Company (2021). The state of fashion 2022. [Online]. Available at: https://www.mckinsey.com/~/media/mckinsey/industries/retail/our%20insights/state%20of%20fashion/2022/the-state-of-fashion-2022.pdf

[8]. Lemon, K. N. & Verhoef, P. C. (2016). Understating customer experience throughout the customer journey. Sage Journals, 80(6).

[9]. Hinsliff, G. (August 17, 2021). Whatever Next? How a middle-of-the-road high-street chain became a retail powerhouse. The Guardian.

[10]. Wright, G. (September, 2021). How Next, which was founded in Leeds, became one of the most reliable forces in retail. The Yorkshire Post.

[11]. Fisher, M., Gallino, S. & Netessine, S. (2019). Retailers are squandering their most potent weapons. Harvard Business Review.

[12]. Lee, Y. M., Cheng, F. & Leung, Y. T. (2005). Exploring the impact of RFID on supply chain dynamics. Proceedings – Winter Simulation Conference, 2, 1145-1152.

[13]. Solaimani, S., der Veen, J. A. A. V., Sobek II, D. K. & Gulyaz, E. (2019). On the application of lean principles and practices to innovation management: A systematic review. The TQM Journal.