1 Introduction

Fluid mechanics is one of the important branches of basic mechanical education in science and engineering disciplines at higher education institutions, and related teaching experiments play a crucial role in the instruction of fluid mechanics, representing a key component of the mechanics curriculum. Classical experiments in fluid mechanics education include the incompressible fluid steady flow energy experiment (i.e., Bernoulli experiment), Venturi experiment, Reynolds experiment, and Karman vortex street experiment. To reduce costs associated with the purchase, assembly, maintenance, and storage of such experimental devices, researchers have developed a series of comprehensive fluid experimental devices, such as those assembled from discarded materials into a space-saving foldable fluid mechanics demonstration experimental device [1], and a multifunctional fluid mechanics experimental platform created by parallel connection around a water storage tank [2]. There are also some more mature large-scale comprehensive experimental devices. Researchers have improved existing Reynolds experimental setups by conducting lateral multi-tube parallel connections or diversified layered modifications of pipelines to meet comprehensive experimental needs [3-5]. Some researchers have also used vertical height differences in water tanks, adjusting water head energy and comparing flow stabilization effects to perform layered experiments in water tanks to achieve comprehensive experimental purposes [6].

From the perspective of development history and usage, current comprehensive fluid mechanics experimental devices are relatively mature. However, deficiencies remain in aspects such as space usage, parts integration, utilization rate, lifespan, and precision, such as: fluid mechanics experimental devices capable of visualizing flow fields, where the density and dissolution speed of tracing agents like red ink or potassium permanganate solution significantly affect experimental precision, and the device interfaces have discontinuities in tube diameter (e.g., necked flat welding flanges) [7-9]. Additionally, some comprehensive experimental devices with viewing windows use corrosion-resistant stainless steel materials as the main components of the experiment, which makes the overall device expensive and unsuitable for mass purchase by universities [10]. These deficiencies are the main reasons limiting the widespread application of high-performance, low-cost fluid mechanics experimental devices. Therefore, this study proposes a new type of modular fluid mechanics comprehensive experimental device, which boasts comprehensive experimental functions, good flow stabilization effects, strong expandability, low cost, and a long service life. The development of this device can greatly promote universities to establish well-equipped, fully functional basic fluid mechanics laboratories, thus improving the related disciplinary training system [11-14].

2 Experimental Device

The modular fluid mechanics comprehensive experimental device can be used to perform Reynolds experiments, Karman vortex street experiments, and nozzle outflow experiments. The device overall is divided into common components and specific components. Common components mainly include the flow stabilization water tank, water storage tank, and fluid circulation components; specific components mainly include the Reynolds outflow component, Karman vortex street open channel component, and nozzle and orifice outflow component.

2.1 Common Components

2.1.1 Water Storage Tank and Fluid Circulation Components

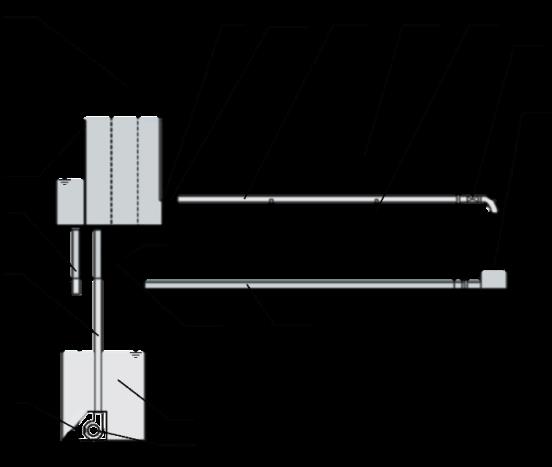

As shown in Figure 1, the water storage tank used in this modular fluid mechanics comprehensive experimental setup measures 700mm×500mm×1000mm. To ensure effective fluid circulation during experiments, the water storage should be at least 80% of the tank’s volume. Based on ergonomic needs, the operating height is approximately 1.3m; hence, a water pump with a maximum lift of 2m is selected. The water pump, inlet pipe, return water filtration trough, and return water pipeline together constitute the fluid circulation components.

Figure 1. Assembled hydrodynamics comprehensive experimental device.

2.1.2 Stabilization Water Tank

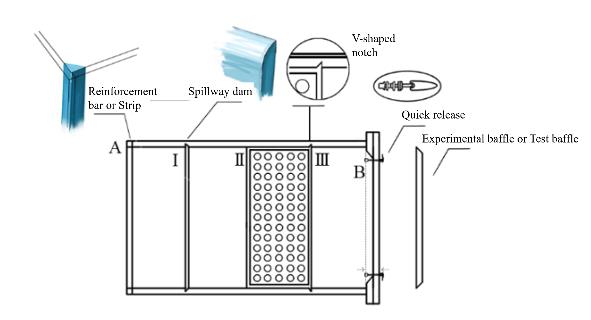

The stabilization water tank, part of the common components, is constructed from PMMA transparent plates and measures 500mm×410mm×250mm. It features an innovatively designed silica gel particle stabilization drawer, creating a removable core structure that is straightforward to disassemble, clean, and maintain. The drawer is filled with silica gel particles of varying diameters (S∅4, S∅6, S∅8) and sealed with multiple plates and baffles. The drawer’s design includes a perforated bottom for quick drainage and a specially designed overflow dam to prevent liquid splashing. The drawer and tank are equipped with V-shaped protrusions and grooves, facilitating easy assembly and providing enhanced sealing and stability, while also preventing damage during maintenance.

|

|

(a) Top view of steady flow tank. |

(b) Steady current drawer |

Figure 2. Water tank for regulating flow.

2.2 Specific Components

The modular fluid mechanics experimental device offers excellent expandability through interchangeable components tailored for various experiments such as Reynolds outflow, Karman vortex street, and nozzle or orifice outflow. It incorporates standardized removable interfaces and self-locking systems to allow quick and efficient component swaps, enhancing the device’s versatility for different experimental setups.

2.2.1 Removable Interface and Corresponding Self-locking System

The newly designed standardized removable interface significantly reduces interface wear from frequent assembly and disassembly, enhancing the feasibility for adding experimental variations. The innovative quick-install self-locking sealing system replaces traditional glued methods, providing initial sealant protection against seepage and strengthening the seal as internal water pressure increases. This system allows for quick changes between experimental setups by simply releasing and swapping baffles and their specific components, streamlining the process for experiment personnel.

2.2.2 Reynolds Outflow Component

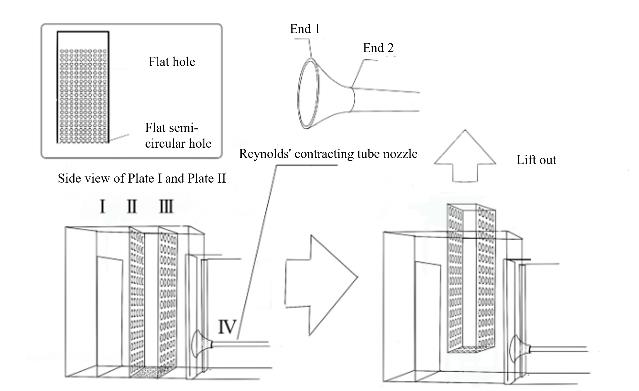

The Reynolds outflow component, which includes a removable baffle compatible with the device’s standardized interface, a tracer dye guide aligned with fluid outflow direction, and an outflow pipe made of PMMA hollow tube material sized ∅20×4. This setup also features an infinite flow valve at the pipe’s rear to adjust fluid flow speed. The component contains a Reynolds tapered nozzle designed with a complex, derivable curve for diameter changes from ∅100×6 to ∅26×6, and is supported by an anti-roll frame to stabilize the outflow pipe.

2.2.3 Karman Vortex Street Open Channel Component

The Karman vortex street open channel component, which features an open section at location A and an overflow dam at location B to manage water levels and prevent splashing. The side baffles are constructed from PMMA transparent plates, measuring 1110mm×400mm×10mm, allowing clear observation of the Karman vortex street phenomenon. Both the overflow dam at location B and the one in the stabilization water tank share an arc-shaped design, with dimensions of 150mm×300mm×10mm, enhancing fluid control and minimizing splashing.

2.2.4 Nozzle and Orifice Outflow Component

The different nozzles and orifices used in this experiment are adjusted using a switching wheel, which is bolted to the stabilization water tank baffle. The nozzle interface diameter is ∅20mm, and nozzles of different shapes can be custom-made according to experimental needs and fixed at positions A, B, C with UV glue.

3 Experimental Methods and Results

3.1 Reynolds Experiment

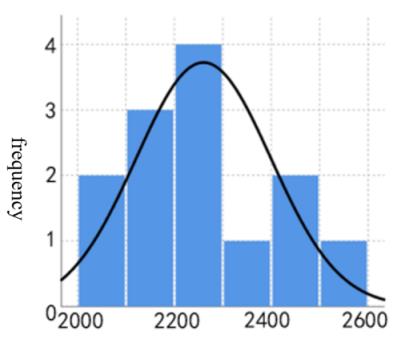

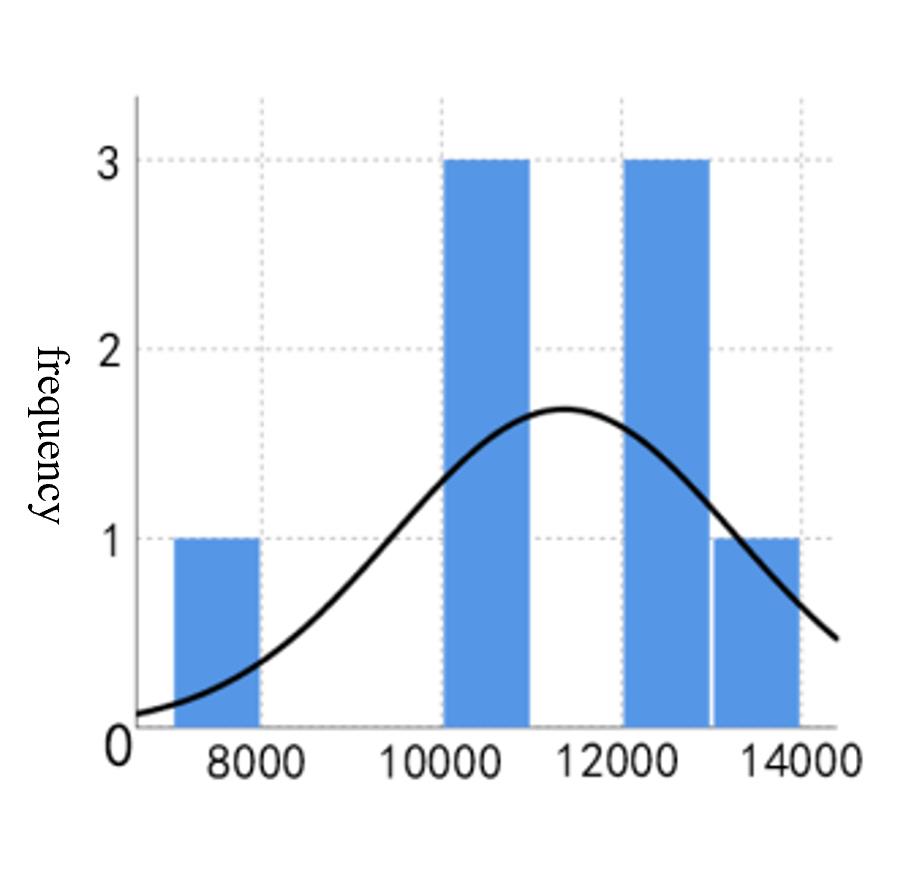

The Reynolds number, a dimensionless value, gauges the influence of fluid viscosity by reflecting the ratio between inertial and viscous forces. It helps identify flow state transitions through critical Reynolds numbers, split into upper and lower thresholds. The upper threshold indicates the shift from laminar to turbulent flow and varies between 5,000 and 40,000, noted for its instability. In contrast, the lower critical Reynolds number, more stable at a value of 2,320, indicates the transition from turbulent back to laminar flow and is widely used in practical settings to determine the flow state [8, 16-18]. In the Reynolds outflow experiments conducted with the designed setup, critical Reynolds numbers were systematically analyzed. As shown in Figure 3, the findings include a single-sample K-S normal test confirming the normal distribution of the lower critical Reynolds numbers with a mean of 2260.7 and a standard deviation of 139.3. The upper critical numbers also normally distribute around a mean of 11362.4 with a standard deviation of 1897. These results align with established research on Reynolds numbers, underscoring the experimental setup’s accuracy and practical utility for studying flow dynamics.

|

|

(a) Lower critical Reynolds number |

(b) Upper critical Reynolds number |

Figure 3. Single sample K-S normal test for upper and lower critical Reynolds number single.

3.2 Nozzle and Orifice Outflow Experiment

The experimental device uses a water head type instantaneous digital flowmeter, monitoring the flow through different nozzles and orifices in real-time. The flow rate qV under the influence of water head H0 for thin-walled nozzles or orifices in free outflow can be calculated using the following equation:

\( q_{V}=φεA\sqrt[]{2gH_{0}}=νA\sqrt[]{2gH_{0}}\ \ \ (1) \)

where φ=1/(1+ζ)1/2 is the velocity factor, ζ is the resistance factor; ε=Ac/A is the contraction factor, Ac and A are the contracted and cross-sectional areas, respectively; ν=εφ is the flow factor; g is the acceleration due to gravity; \( H_{0}=H+\frac{αv_{0}^{2}}{(2g)} \) , since the water head \( \frac{αv_{0}^{2}}{(2g)} \) due to the velocity of nozzle and orifice outflow is minor, this term can be neglected.

The experiments depicted in Figure 6, showcasing various outflow projects from left to right—namely orifice, right-angle nozzle A, conical nozzle, and right-angle nozzle B—reveal significant variations in fluid flow rates despite minor differences in water levels. As summarized in Table 2, these variations suggest that the nozzle and orifice shapes, alongside changes in the contraction area, substantially influence fluid outflow velocity. Further comparative analysis confirms that the experimental data aligns well within acceptable error margins with empirical values from Professor Mao Genhai’s “Engineering Fluid Mechanics Experiment Guidebook” [16,17]. This alignment attests to the high accuracy and practical utility of this device for conducting detailed studies on nozzle and orifice outflow dynamics.

Table 2. Data of nozzle and orifice outflow experiment

Item |

orifice |

Right Angle nozzle A |

Conical nozzle |

Right Angle nozzle B |

Flow qv(10-6m3/s) |

432.93 |

396.83 |

91.00 |

110.99 |

Working head H0(10-2m) |

7.18 |

7.95 |

7.95 |

13.65 |

Outflow area A(10-4m2) |

5.31 |

3.80 |

3.80 |

0.79 |

Flow factor ν |

0.69 |

0.84 |

0.191 |

0.87 |

Shrink section Ac(10-4m2) |

3.80 |

3.80 |

0.79 |

0.79 |

Shrinkage factor ε |

0.72 |

1 |

0.21 |

1 |

Flow factor φ |

0.96 |

0.84 |

0.93 |

0.87 |

Drag factor ζ |

0.08 |

0.42 |

0.16 |

0.33 |

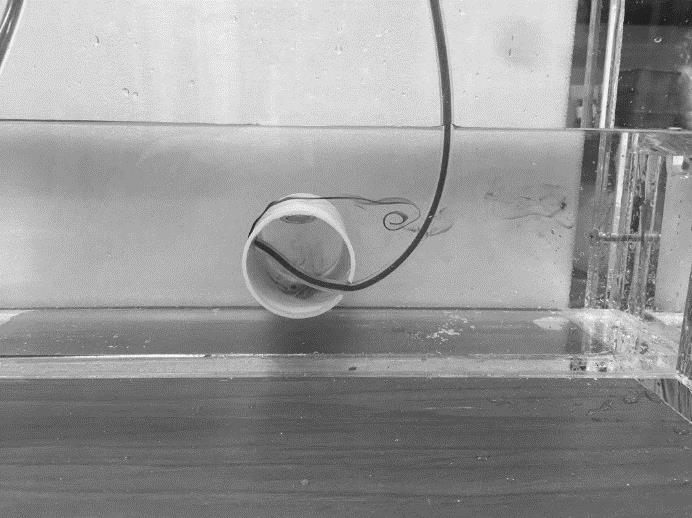

3.3 Karman Vortex Street Experiment

This modular fluid mechanics experimental device offers an outstanding platform for observing the Karman vortex street phenomenon. Experiment personnel can finely adjust the tracer agent’s flow rate with a high-precision syringe pump (SPLab02) to meet specific experimental needs. When the flow rate is set correctly, the Karman vortex street phenomenon manifests. Observers can then directly view or capture this phenomenon through the device’s transparent PMMA baffle, as shown in Figure 4, providing a clear and direct visualization of the fluid dynamics involved.

Figure 4. Picture of Karman vortex street.

4 Conclusion

In summary, this new modular fluid mechanics experimental device offers several advantages over traditional and similar devices: (1) It uses innovative removable stabilization components that improve both maintainability and stability; (2) Its design includes standardized removable interfaces that enhance expandability and reduce wear from frequent disassembly and reassembly; (3) The operation and observation platform, made from transparent PMMA, provides excellent sealing, ease of operation, and cost-effectiveness. Additionally, destructive testing has shown that the inclusion of reinforced bars significantly enhances the device’s heat and corrosion resistance. During the educational phase, this device affords students substantial freedom to expand experiments, fostering engagement and cultivating their innovation and independence. Overall, this device is instrumental in developing well-equipped, fully functional basic fluid mechanics labs in universities, enhancing the educational framework within the discipline.

Acknowledgement

Zhao Runchen, Shen Wenhao are co-first authors and contributed equally to this work.

References

[1]. Zhang Yun. Simple Fluid Mechanics Experimental Device [P]. CN108932888A, 2018-12-04.

[2]. Han Qi, Zhang Tao, Lü Dongli, Wen Songqing, Zhang Qichao. A Multipurpose Fluid Mechanics Experimental Device Platform [P]. CN208706109U, 2019-04-05.

[3]. Ma Li. A Comprehensive Experimental Device for Fluid Mechanics [P]. CN206480255U, 2017-09-08.

[4]. Liu Huabin, Tang Lei, Mu Guochao, Yu Rui, Huang Xiaoling, Xie Xuming. A Comprehensive Experimental Device for Fluid Mechanics [P]. CN108877429A, 2018-11-23.

[5]. Zou Lan, Wei Zhenshu, Zhang Jianping, Shi Chongyu, Cui Runhe. Design and Research on Comprehensive Fluid Mechanics Experimental Device [J]. Journal of Henan Normal University (Natural Science Edition), 1998(03): 100-102+107.

[6]. Yue Lifang. Comprehensive Experimental Device for Fluid Mechanics [P]. CN208507043U, 2019-02-15.

[7]. Wei Yuxuan, Li Zecheng, Wu Yefeng. Improvements to Fluid Mechanics Experimental Instruments at North China University of Science and Technology [J]. Housing, 2020(03):181.

[8]. Wang Naizhi. Development of a Small-Scale Visual Fluid Mechanics Experimental Device [J]. Hydraulics and Pneumatics, 1983(02): 39-42.

[9]. Li Xinhong, Li Yongnian, Lei Renchao, Cai Xiaoyin. Comprehensive Experimental Device for Fluid Mechanics [P]. CN203311698U, 2013-11-27.

[10]. Zhang Xiutao, Chen Yuanyuan, Zhao Lijing, Feng Chaohui, Sun Mingzhou, Xu Taotao. Comprehensive Fluid Mechanics Experimental Device [P]. CN305126446S, 2019-04-23.

[11]. Yang Song, Zhu Xianyong, Yu Ping, Wang Hui, Wang Jili. Exploring and Building the Experiment Teaching of Fluid Momentum Equation under the New Engineering Background [J]. Laboratory Research and Exploration, 2019, 38(06): 206-209+268.

[12]. Xu Ning, Mou Jianming, Wang Mei, Zheng Xuelun. Practice and Thought on the Connotation Design of Boutique Experimental Projects in Chemical Engineering [J]. Experimental Technology and Management, 2009, 26(03): 25-26+30.

[13]. Luo Jie. Cultivating Students’ Innovative Thinking Abilities in Fine Chemical Experiments [J]. Laboratory Research and Exploration, 2008(02): 5-7.

[14]. Chen Qin, Shen Yuping. Experimental Teaching and Cultivation of Innovative Talents [J]. Higher Education Forum, 2002(05): 74-76.

[15]. Du Dongyun, Fang Yunjin, Xiao Wende. An Improved New Vertical Screen I. Fluid Mechanics [J]. Journal of East China University of Science and Technology, 2000(03): 251-255.

[16]. Chen Jide. On Critical Reynolds Numbers [J]. Textbook Communications, 1986(04): 28.

[17]. Zhang Zhuxin, Yu Lei, Qi Zhonghua. Discussion on the Use of Critical Reynolds Numbers in Engineering Fluid Mechanics [J]. Lubrication and Sealing, 2001(01): 71-65.

[18]. Li Qingxiang. Modern Precision Instrument Design [M]. Tsinghua University Press, 2004: 507-510.

[19]. Mao Genhai. Guidebook for Engineering Fluid Mechanics Experiments [Z]. Hangzhou Yuanliu Science and Technology, 2008: 33-37

[20]. Zhang Guiping, Ding Li, Peng Yong. Design of Comprehensive Experiments in Chemical Process [J]. Experimental Technology and Management, 2008(10): 42-44.

Cite this article

Zhao,R.;Shen,W.;Bu,T.;Song,L.;Sun,G.;Jiao,Y. (2024). A new assembled experimental device for fluid mechanics. Theoretical and Natural Science,36,205-210.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Mathematical Physics and Computational Simulation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhang Yun. Simple Fluid Mechanics Experimental Device [P]. CN108932888A, 2018-12-04.

[2]. Han Qi, Zhang Tao, Lü Dongli, Wen Songqing, Zhang Qichao. A Multipurpose Fluid Mechanics Experimental Device Platform [P]. CN208706109U, 2019-04-05.

[3]. Ma Li. A Comprehensive Experimental Device for Fluid Mechanics [P]. CN206480255U, 2017-09-08.

[4]. Liu Huabin, Tang Lei, Mu Guochao, Yu Rui, Huang Xiaoling, Xie Xuming. A Comprehensive Experimental Device for Fluid Mechanics [P]. CN108877429A, 2018-11-23.

[5]. Zou Lan, Wei Zhenshu, Zhang Jianping, Shi Chongyu, Cui Runhe. Design and Research on Comprehensive Fluid Mechanics Experimental Device [J]. Journal of Henan Normal University (Natural Science Edition), 1998(03): 100-102+107.

[6]. Yue Lifang. Comprehensive Experimental Device for Fluid Mechanics [P]. CN208507043U, 2019-02-15.

[7]. Wei Yuxuan, Li Zecheng, Wu Yefeng. Improvements to Fluid Mechanics Experimental Instruments at North China University of Science and Technology [J]. Housing, 2020(03):181.

[8]. Wang Naizhi. Development of a Small-Scale Visual Fluid Mechanics Experimental Device [J]. Hydraulics and Pneumatics, 1983(02): 39-42.

[9]. Li Xinhong, Li Yongnian, Lei Renchao, Cai Xiaoyin. Comprehensive Experimental Device for Fluid Mechanics [P]. CN203311698U, 2013-11-27.

[10]. Zhang Xiutao, Chen Yuanyuan, Zhao Lijing, Feng Chaohui, Sun Mingzhou, Xu Taotao. Comprehensive Fluid Mechanics Experimental Device [P]. CN305126446S, 2019-04-23.

[11]. Yang Song, Zhu Xianyong, Yu Ping, Wang Hui, Wang Jili. Exploring and Building the Experiment Teaching of Fluid Momentum Equation under the New Engineering Background [J]. Laboratory Research and Exploration, 2019, 38(06): 206-209+268.

[12]. Xu Ning, Mou Jianming, Wang Mei, Zheng Xuelun. Practice and Thought on the Connotation Design of Boutique Experimental Projects in Chemical Engineering [J]. Experimental Technology and Management, 2009, 26(03): 25-26+30.

[13]. Luo Jie. Cultivating Students’ Innovative Thinking Abilities in Fine Chemical Experiments [J]. Laboratory Research and Exploration, 2008(02): 5-7.

[14]. Chen Qin, Shen Yuping. Experimental Teaching and Cultivation of Innovative Talents [J]. Higher Education Forum, 2002(05): 74-76.

[15]. Du Dongyun, Fang Yunjin, Xiao Wende. An Improved New Vertical Screen I. Fluid Mechanics [J]. Journal of East China University of Science and Technology, 2000(03): 251-255.

[16]. Chen Jide. On Critical Reynolds Numbers [J]. Textbook Communications, 1986(04): 28.

[17]. Zhang Zhuxin, Yu Lei, Qi Zhonghua. Discussion on the Use of Critical Reynolds Numbers in Engineering Fluid Mechanics [J]. Lubrication and Sealing, 2001(01): 71-65.

[18]. Li Qingxiang. Modern Precision Instrument Design [M]. Tsinghua University Press, 2004: 507-510.

[19]. Mao Genhai. Guidebook for Engineering Fluid Mechanics Experiments [Z]. Hangzhou Yuanliu Science and Technology, 2008: 33-37

[20]. Zhang Guiping, Ding Li, Peng Yong. Design of Comprehensive Experiments in Chemical Process [J]. Experimental Technology and Management, 2008(10): 42-44.