1. Introduction

Building on the findings, the integration of technology into healthcare and rehabilitation has witnessed significant advancements in recent years, with a particular focus on automated wearable devices and low-pressure fluid actuators. These innovations hold tremendous promise in enhancing the efficiency of rehabilitation therapies, catering to the diverse needs of individuals with varying degrees of physical limitations. Fluid-driven actuators are the most widely used artificial muscles due to their simplicity, large actuation stress and deformation, high energy efficiency, and low cost [1].

Complementing this trend, low-pressure fluid actuators have garnered attention for their potential to revolutionize rehabilitation interventions, particularly in cases where traditional methods may be limiting. These actuators operate at lower pressures, providing a gentler and more controlled approach to movement assistance. This feature is particularly advantageous in scenarios involving patients with compromised mobility, where precision and safety are paramount.

The existing actuator comprises two components: a pouch made of TPE and a foldable mesh tube after heating by heat gun. The mesh tube is designed to enable pressurization without expanding, effectively retaining air and allowing for increases in pressure without a corresponding increase in volume. Importantly, its easy integration into clothing, rather than mimic the skin, presents a distinct advantage. At the end of the actuator, a strip functions as an end-effector, facilitating pulling forces.

To enhance the contraction performance, the mesh inside the pouch was replaced with a zigzag pattern, and contraction tests were conducted to determine the optimal dimensions. Initially, materials for the pouch were selected by observing the contraction effects of pouches made from different materials, aiming to identify the most suitable one. Subsequently, the dimensions of the zigzag pattern and the shape of the pouch were redesigned for improved testing accuracy. This research seeks to refine and optimize the actuator design, contributing to advancements in actuation technology for various applications.

2. Low-Pressure Fluid Actuators

2.1. Working Principle of the Actuator

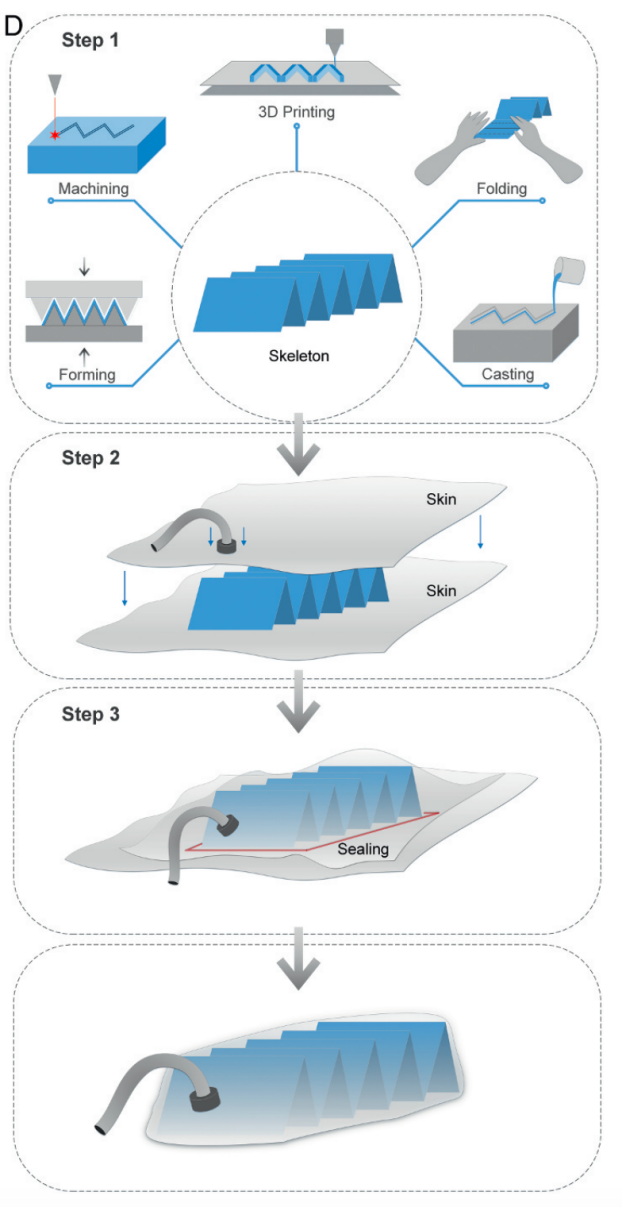

Initially, a zigzag pattern shape was established for a sample test to evaluate the contraction characteristics of the actuator. Pouches were made by using various materials to be tested under the comprehensive examination of how each material influenced the actuator's contraction behavior, as shown in Fig. 1. During this process, there were no specific designs for the dimensions of the zigzag or the shape of the pouch, as the primary goal was to conduct a preliminary sample test. The assessment of the contraction performance across different materials provided valuable insights for subsequent design modifications. This process allowed for continuous improvement and adaptation. The methodology of refining the zigzag pattern and pouch shape based on empirical observations forms a crucial part of the research. This approach contributes significantly to the development of an actuator with improved contraction capabilities. As a result, the detailed exploration of various materials and shapes during the sample test phase laid the foundation for informed decision-making in subsequent design iterations.

2.2. Actuator Research Work

Figure 1. Fabrication Process: A standard actuator can be quickly fabricated in three steps: (1) skeleton construction, (2) skin preparation, and (3) fluid-tight sealing [1].

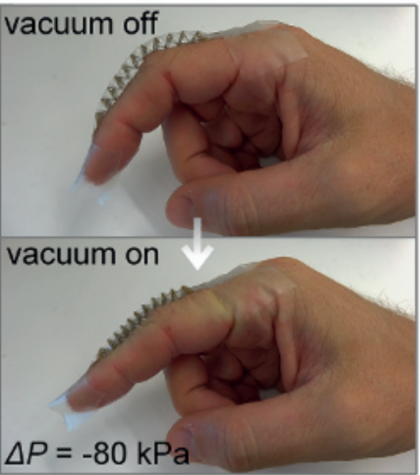

Building on the initial findings, the research encompassed two experimental aspects aimed at enhancing the observability of the entire actuator's contraction effects. One side is to make sure which kind of material is most appropriate for the pouch and the other side is about the insert zigzag, as shown in Fig. 2. There are three main types of materials work well for pouches in the contraction process: TPE, TPU, and textile. To provide a clearer view of the actuator's movement, one side was replaced with transparent materials—Thermoplastic Elastomer (TPE) and Thermoplastic Polyurethane (TPU). TPE is a kind of soft plastic with high flexibility, was initially chosen but presented challenges due to its softness obstructing the air inlet upon opening the vacuum valve. Then, TPU combines the elasticity of plastic with the processability of thermoplastics, was selected for its enhanced thickness and durability. The incorporation of a valve at the air inlet ensured unobstructed airflow and efficient operation of the actuator during the vacuum and pressurization cycles. This process solve the limitations encountered with TPE and introduced a more robust material with thick TPU, optimizing the actuator's functionality and reliability.

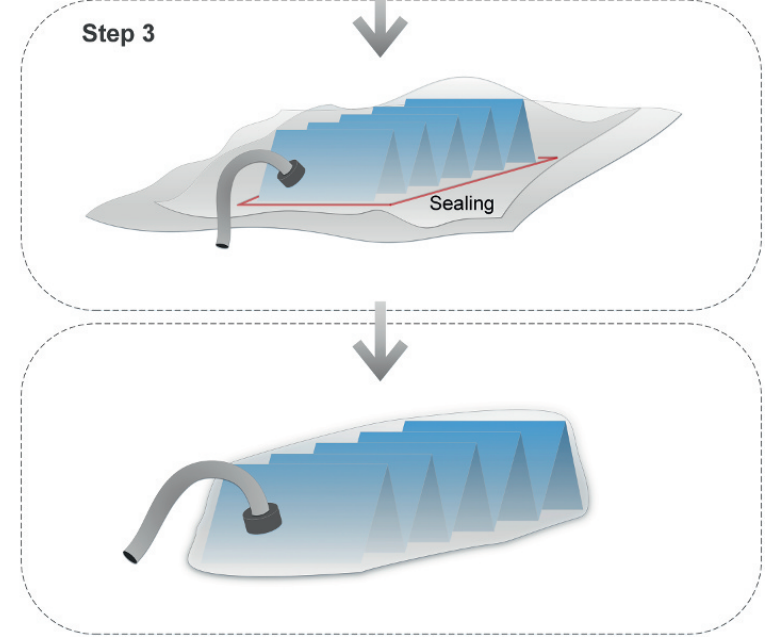

Figure 2. Photograph of a typical expanded metal tube and the definition of parameters for a single cell [2].

The previous design for insert is the retractable mesh tube. The structure of mesh tube is pretty similary to metal tube, which makes the whole tube can flexible expansion and contraction [2]. In the field of medical device design, the substitution of mesh with a zigzag pattern arises from various considerations specific to the application and design requisites. The zigzag configuration exhibits greater flexibility and adaptability, particularly in interfacing with irregular biological tissue shapes, accommodating dynamic changes between the apparatus and the tissue. Furthermore, the zigzag structure enhances strength and stability, critical for devices requiring precision or stability in specific regions. To optimize the properties of the energy absorbers, multicellular structures and lattice structures with various topologies were proposed over the last decade due to their lightweight, superior specific stiffness and strength [2]. Additionally, the zigzag structure often simplifies manufacturing processes and requires fewer materials, contributing to cost reduction and sustainable design practices.

When comparing zigzag to mesh tubes in the design of low-pressure fluid actuators, significant differences in flexibility and performance optimization emerge. Chiral lattice inserts are one of the most interesting examples that have been utilized in vibration attenuation applications. Initial studies on chiral inserts have demonstrated that significant energy absorption properties and low-frequency bandgaps can be achieved by using such inserts [3]. Mesh tubes have fixed parameters that are not easily adjustable. Before being inserted into the pouch, the mesh must be folded and subjected to heat treatment to become retractable. However, this retractability tends to diminish over time, reducing the actuator's effectiveness and reliability. In contrast, the zigzag pattern offers greater versatility. It can be crafted from various materials and allows for adjustments in critical parameters such as width, gap size, and gap distance. These adjustments enable the optimization of the actuator’s retraction capabilities and overall performance. The ability to change these parameters helps in maximizing the actuator's efficiency and adaptability to different applications. This flexibility is particularly advantageous in applications requiring precise and sustained performance over time. Therefore, replacing mesh tubes with zigzag patterns is a superior approach in actuator design, offering enhanced functionality and longevity.

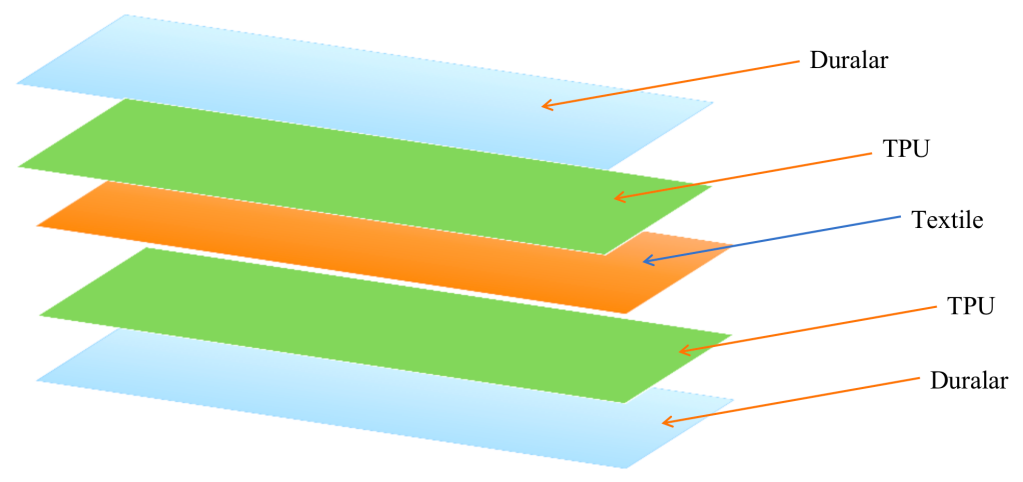

Figure 3. Schematic Diagram (Photo/Picture credit: Original).

To transition to the experimental setup, it is important to note that length was found to have minimal impact on contraction. The designed zigzag pattern included laser-cut duralar at both ends, sandwiching two layers of TPU in the middle, with an innermost layer of textile. To ensure the material's contractility after the thermal pressing process, the zigzag pattern was folded and secured with clips or tape. A new pouch design conforming to the shape of an aluminum plate was devised to address leakage issues caused by small bubbles during heat sealing. This design allowed for a two-step sealing process during experimentation. Initially, both sides of the pouch were sealed by heat press. Subsequently, after securing the zigzag in place, low-temperature heat pressing was applied to the two ends. The process was finalized by affixing the two ends of the zigzag with small clips for testing under conditions ensuring the entire actuator was airtight. The systematic adjustment of crucial parameters—gap size, duralar height, and width—based on test results optimized the actuator's contraction efficiency. The laser-cut duralar at both ends served as stabilizing elements, contributing to the actuator's structural integrity. The middle layers of TPU provided flexibility and responsiveness during contraction, while the innermost layer of textile imparted additional strength to the actuator assembly, as shown in Fig. 3.

3. Practical Applications

The design and manufacturing of low-pressure fluid actuators for self-contained wearable devices have significant applications in people’s daily lives, particularly in enhancing human mobility and convenience. It has been shown that robotic gravity compensation of the affected upper limb can lead to improved motor function as it off-loads and stabilizes the shoulder, allowing stroke survivors to focus instead on the smaller distal muscles of the elbow, wrist, and hand. The robots used in these studies have typically been static rigid framed robots designed for research and clinical purposes [4]. It can be integrated into various wearable technologies to assist individuals with limited mobility, such as the elderly or those with physical disabilities. By mimicking natural muscle movements, this actuator provides additional support and strength, making it easier for users to perform daily activities like walking, lifting objects, or climbing stairs.

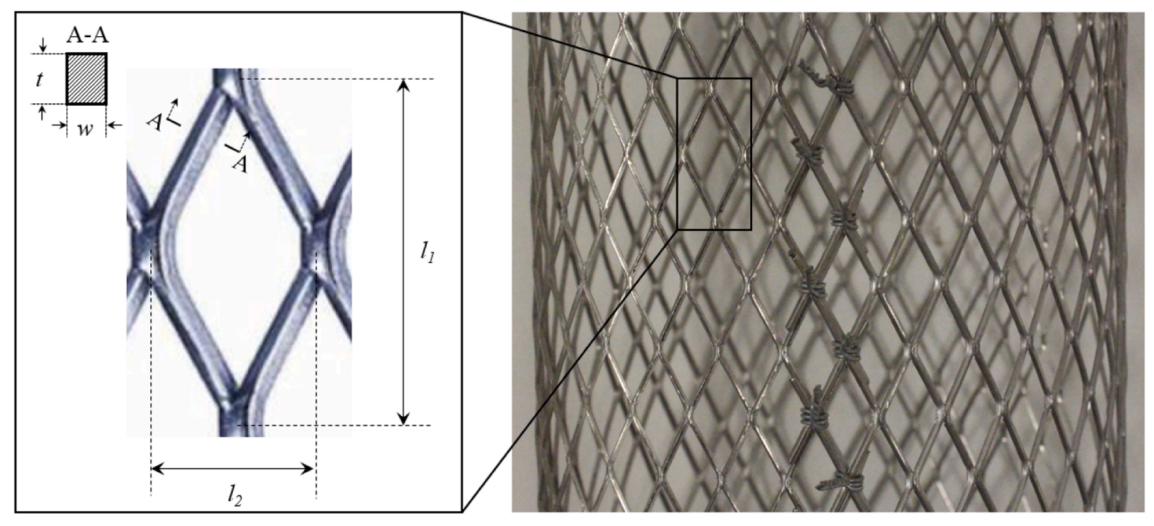

Figure 4. Miniature linear actuators with PEEK zigzag origami skeletons and PVC skins. Biocompatible for medical and wearable applications [1].

There are many specific artificial muscle technologies. Each of these technologies has its own capabilities and application opportunities. However, there are also technical issues that almost all the muscle technologies have in common. These include issues of batch-fabricating micro actuators, electrical interconnection, and packaging, mechanically coupling the micro actuators' outputs to produce macroscopic forces, and preventing the electrical or mechanical failure of one micro actuator from reducing the muscle's overall performance [5]. In addition to daily activities, in sports and fitness, these wearable devices can enhance athletic performance by providing additional force during physical activities, reducing fatigue, and preventing injuries. For example, exoskeletons equipped with low-pressure fluid actuators can help athletes train more effectively by supporting joints and muscles during intense workouts, as shown in Fig. 4.

Moreover, these actuators can be utilized in wearable devices designed for workplace safety and productivity. In industrial settings, workers can wear suits integrated with these actuators to assist in lifting heavy objects, thereby reducing the risk of strain or injury and improving overall efficiency. The use of nonlinear materials, large displacements, and distributed actuation make designing and optimizing soft robots vastly more challenging than rigid robots. Rather than modeling a robot as a set of rigid links with exact displacements and rotations, soft robot designers generally employ one of the analytical or numerical methods previously discussed as the basis for design optimization. The methods broadly trade-off accuracy for generality or speed, hence soft robot design optimizations focus on elementary components. In contrast, evolutionary design generates complex morphologies but the simulations translate poorly into realworld performance. Automating the design of soft robots would enable the rapid generation of application-specific soft robots and accelerate the growth of soft robotics [6].

Overall, the application and adaptability of low-pressure fluid actuators make them valuable components in a wide range of wearable technologies, significantly improving quality of life, enhancing performance, and providing critical support in various aspects of daily life.

4. Conclusion

This research extends beyond the field of actuation technology. The improved actuator design characterized by its optimized contraction efficiency and ability of compression, holds significant promise for integration into healthcare and rehabilitation technologies. For instance, when incorporated into wearable devices, this actuator can provide critical assistance to individuals with mobility impairments, aiding in movements such as walking and lifting. The ability to change the actuator's performance to meet specific needs enhances its applicability in personalized medical treatments and rehabilitation programs. Moreover, this research aligns with broader trends in the integration of advanced technology into various domains, including soft robotics and wearable devices. The findings work for future developments and innovations, fostering progress in areas where precise and efficient actuation is important. As technology continues to evolve, the insights gained from this study will inform the development of more sophisticated and effective actuators, contributing to advancements in robotics, assistive devices, and beyond.

In summary, this research deepened the understanding of low-pressure fluid actuators and demonstrated practical improvements that enhance their functionality and broaden their applicability. The study might be able to influence future innovations, driving progress in both specialized actuation technology and its integration into broader technological and healthcare contexts.

References

[1]. Shuguang Li, Daniel M. Vogt, Daniela Rus, Robert J. Wood. Fluid-driven origami-inspired artificial muscles. Proceedings of the National Academy of Sciences of the United States of America, 2017, 114(50): 13132-13137.

[2]. Wangfan Zhou, Dora Karagiozova, Xudong Ren, Guoxing Lu. Thin-Walled Structures. ScienceDirect, 2024, 200: 111981.

[3]. Osama Abdeljaber, et al. Optimization of linear zigzag insert metastructures for low-frequency vibration attenuation using genetic algorithms. Mechanical Systems and Signal Processing, 2017, 84(Part A): 625-641.

[4]. Ciarán T. O'Neill, et al. Unfolding Textile-Based Pneumatic Actuators for Wearable Applications. Soft Robotics, 2022, 9(1): 14-22.

[5]. Ronald E. Pelrine, et al. Review of Artificial Muscle Approaches. SRI International.

[6]. Matheus Xavier, Ali Zolfagharian. Soft Pneumatic Actuators: A Review of Design, Fabrication, ModelingSensing, Control and Applications. IEEE. June 2022

Cite this article

Zhang,Y. (2024). Design and Fabrication of Low-Pressure Fluid Actuators for Self-Contained Wearable Devices. Theoretical and Natural Science,70,85-90.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Biological Engineering and Medical Science

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Shuguang Li, Daniel M. Vogt, Daniela Rus, Robert J. Wood. Fluid-driven origami-inspired artificial muscles. Proceedings of the National Academy of Sciences of the United States of America, 2017, 114(50): 13132-13137.

[2]. Wangfan Zhou, Dora Karagiozova, Xudong Ren, Guoxing Lu. Thin-Walled Structures. ScienceDirect, 2024, 200: 111981.

[3]. Osama Abdeljaber, et al. Optimization of linear zigzag insert metastructures for low-frequency vibration attenuation using genetic algorithms. Mechanical Systems and Signal Processing, 2017, 84(Part A): 625-641.

[4]. Ciarán T. O'Neill, et al. Unfolding Textile-Based Pneumatic Actuators for Wearable Applications. Soft Robotics, 2022, 9(1): 14-22.

[5]. Ronald E. Pelrine, et al. Review of Artificial Muscle Approaches. SRI International.

[6]. Matheus Xavier, Ali Zolfagharian. Soft Pneumatic Actuators: A Review of Design, Fabrication, ModelingSensing, Control and Applications. IEEE. June 2022