1. Introduction

Specific strength, defined as the ratio of a material's strength to its density, is an important factor in judging whether a material is suitable for use in automotive components. This is because reducing its own weight while ensuring that the material meets safety conditions is an excellent way to improve fuel efficiency. Numerous experiments have been conducted to measure and compare the specific strength of various materials. And people have also carried out some experiments to improve the specific strength. The machining and mechanical behavior of silicon carbide and aluminum nitride (AlON) nanocomposites were studied. Zhao [10] et al. found through experiments that AlON has a high specific strength and is widely used as an automotive material. Xue et al. established a tensile test to measure the specific strength of carbon fiber composites, which showed that these lightweight materials can meet high tensile loads [1]. Similarly, Hirsch et al. [2] combined experimental tensile tests and theoretical models to improve the specific strength of aluminum alloys by adding nano-scale reinforcement materials. Gong et al. [3] also carried out tensile tests on titanium alloys and obtained remarkable strength values.

This paper assumes that when the two properties of specific strength and corrosion resistance are used to evaluate ceramic, aluminum alloy, titanium alloy, and carbon fiber composites, carbon fiber will outperform other materials in comparison due to the combination of its high strength-to-weight ratio and excellent resistance to environmental factors. This predictive analysis aims to explore the potential of carbon fiber as the most viable material for future automotive applications.

2. Ceramic

2.1. Ceramic – specific strength

Ceramic materials, whether natural or synthetic, are inorganic compounds that are processed at high temperatures. These ceramic materials have unique properties of polycrystalline or amorphous solid structures, which can make them valuable in a variety of applications. For example, the high hardness properties of ceramics, which make them effectively resistant to wear and scratching tools, so ceramic materials can be made into tools such as carving knives.

In addition, due to its good biocompatibility and corrosion resistance, ceramics have been widely used in the medical field, such as in the production of artificial joints, ceramics have become an ideal choice. However, one of the fatal drawbacks of ceramic materials is that they are extremely brittle, which means that they tend to break when impacted. The high hardness of ceramics also makes them difficult to process and shape, so ceramics need a new production line, due to the replacement of the original mature production line to prepare special processes and equipment, compared with mature production materials, which greatly increases the cost of production.

Additionally, ceramics exhibit excellent high-temperature resistance, maintaining stable performance in extreme heat, making them ideal for high-temperature components in the aerospace industry. Their exceptional chemical stability further enhances their utility, as they are not easily corroded by acids, alkalis, or other chemicals, making them suitable for chemical pipelines and containers.

Ceramics are super hard, but they can break easily if you drop them, kind of like how a ceramic plate shatters on the floor. They're tough to shape and make, and you need special tools and steps to do it. That means they cost more to produce. Also, getting the right materials and making things the right way usually makes ceramic stuff pricier. Even so, people use ceramics a lot in electronics, flying machines, taking care of our health, and working with chemicals. Ceramics have some special qualities that researchersreally need for these jobs.

Ceramic materials are great at dealing with heat and rust, but they can break easily. This flaw can make cars less safe because the parts can crack under stress or if they get hit. [4]. Experts have been working on making ceramics tougher. They've tried adding different materials and tiny strengtheners. It's worked – ceramics can now better withstand hits and still handle high heat just fine. [4].

Figure 1: Oxide ceramic matrix composites exhaust ground test demonstrator consisting of a 1.60m diameter nozzle (showing underneath the titanium-alloy faring) and 1.14m diameter by 2.34 m conical center body with titanium end cap inspection portal (Courtesy of Wiley, Steyer [7])

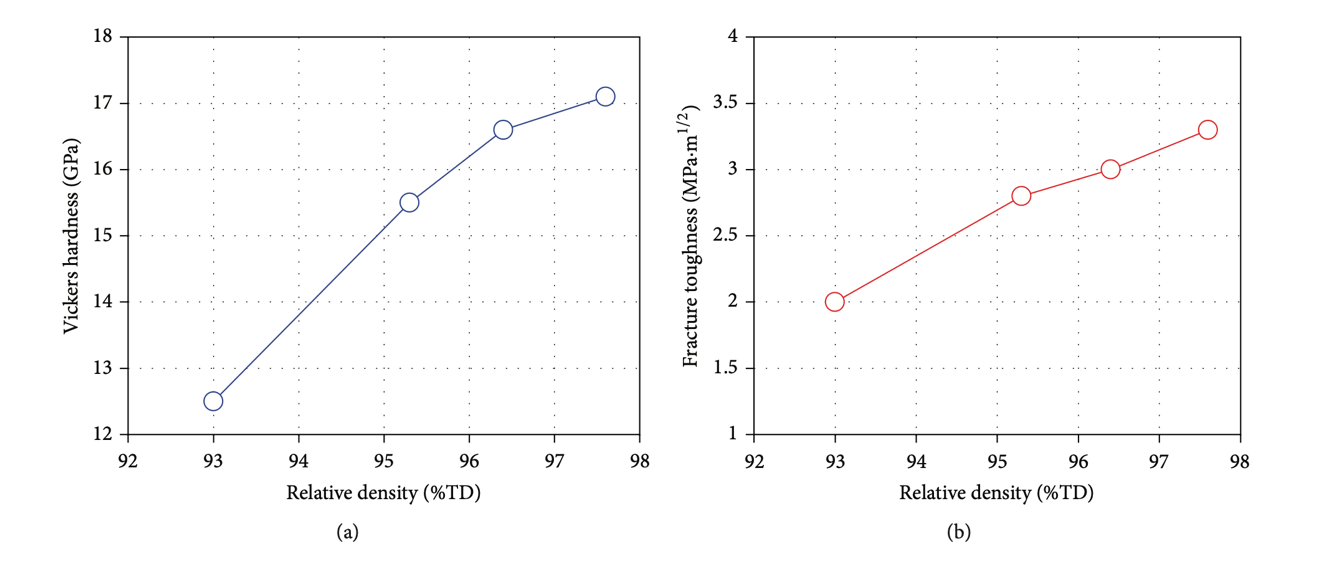

Aguilar-Elgue ́zabal and Bocanegra-Bernal [8,9] studied the fracture behavior of alumina ceramic reinforced with a mixture of 0.05 wt% es + 0.05 wt% SWCNTs. Although small amounts of CNTs added to the alumina matrix, the results showed a general decrease in Vickers hardness and fracture toughness for these samples compared to the monolithic alumina matrix [4]. Also, researchers tested the effects of SWC- NTs on the hardness and flexural strength of alumina matrix composites [5]. Samples of fully dense Al2O3 and SWCNTs composites with 1, 2, 5, and 10 vol% of SWCNTs were fabricated by colloidal processing and tested. The results showed neither increase nor decrease of hardness for samples with 1 vol% SWCNTs with respect to monolithic alumina. In addition, composites with higher SWCNTs content (3, 5, and 10 vol%) showed a 25% reduction in hardness. Not only was there a reduction in hardness, but a similar trend was found in the bending strength, which was significantly reduced (48.7% at 2 vol%) in samples with higher SWCNTs content.

This experiment uses mechanical tests such as bending tests and impact tests to accurately assess the strength and toughness of the material. This research focuses on optimizing the sintering process by controlling temperature and duration, and fine-tuning the amount of reinforcement material added to the ceramic matrix. These variables are carefully adjusted to study their effect on the final mechanical properties [4]

The data show a consistent trend: with the optimization of sintering temperature, the addition of reinforcement material is 5-10%, and the toughness of the ceramics is significantly improved. Specifically, the impact toughness of the ceramics increased by about 20%, with the measured value increasing from 8.5 MPa·m^0.5 to 10.2 MPa·m^0.5[4]. This trend suggests that controlled sintering processes and precise addition of reinforcement materials are key factors in improving the toughness of ceramics.

Due to the observed 20% improvement in toughness, this reflects the effectiveness of optimizing the sintering process and the role of reinforcing materials. According to the modified ceramics have enhanced toughness and make these ceramics more elastic to impact forces, which indicates their potential use in applications where high mechanical strength is required under stress. However, despite these advances, ceramic materials still face limitations compared to carbon fiber composites, especially when handling performance is critical under extreme conditions of specific strength and strength. [1]

Figure 2: Variation of (a) Vickers hardness and (b) fracture toughness with relative density for various nanocomposites [10]

2.2. Ceramics – corrosion resistance

This research is not to improve the corrosion resistance of ceramic materials by changing the internal structure of ceramics, but by leaving oxide coatings and composite coatings on the surface. The study used a series of corrosion tests and thermal cycling tests to evaluate the effectiveness of these materials.

Corrosion tests: These are carried out in a controlled salt spray chamber where both coated and uncoated ceramic samples are exposed to a highly corrosive environment for a specified period of time. The corrosion rate is measured by analyzing the mass loss of the sample over time.

Researchers run a thermal cycle test on coated ceramic pieces. They get hot, then cool down quickly. This shows if they can handle sudden temperature changes without breaking down. To check how fast they rust, researchers measure how much weight they lose after the rust test on a very accurate scale. Researchers write down these numbers to figure out the rust speed in milligrams per square centimeter per hour.

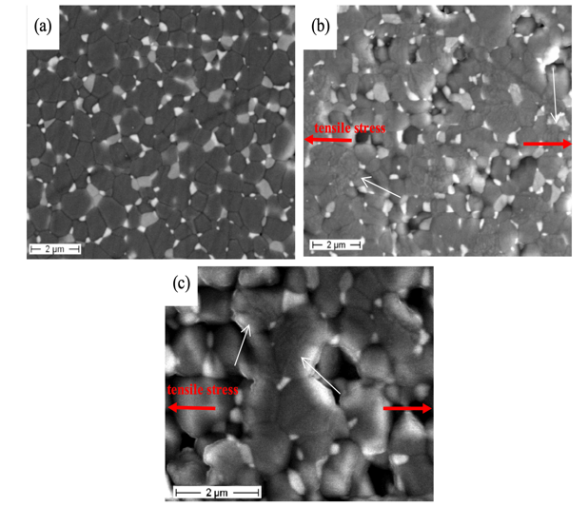

Figure 3: FESEM micrographs of AZY submitted to flexural testing at 1500 ° C. (a) Un-loaded area; (b) lower- and (c) higher-magnification images of the area submitted to tensile stress (loading direction shown by red arrows; microcracks by white arrows) [1]

For seeing how the structure holds up, researchers look at the sample closely and use a special microscope before and after the heat test. We're checking for tiny cracks or any damage on the surface. Our studies find that the special coating on the ceramics makes them way better at not rusting. When researchers put them in a salty mist, the rust speed drops by 40%, from 1.5 mg/cm2/h to just 0.9 mg/cm2/h. Plus, after 50 times of heating and cooling, the coated pieces kept their shape with barely any damage. [9].

The rise in how well the ceramics can resist rust, measured to be around 40%, shows that the special coatings and hot pressing really do their job. This boost means that the coatings help the ceramics last longer and keep their strength. Also, using hot pressing has helped a lot. So, these improvements might mean researchers can use ceramics in places where researchers need them to be strong and not get rusty [8].

Although ceramics have gotten better, they're still not as good as carbon fiber when things get tough, and you need something super strong that's also easy to shape. People often pick carbon fiber for jobs like this because it's strong for its weight and not too hard to work with. But as researchers get smarter about materials, researchers might be able to make ceramics less likely to break and use them more in making cars. This study examines how well ceramic materials with new coatings hold up against rust and keep their shape. Researchers put these materials through tough long-term rust tests and heat tests to see how they do [1].

Researchers tested how well-coated ceramics can stand up to rust by putting them in a salt mist room for a while, like they're in a place that could wear them down. They did really great and even after a bunch of tests, the ceramics outside didn't get messed up or cracked. When researchers measured it all out, researchers found out the rusting slowed down by 40%; it went from 1.5 mg for every square centimeter each hour to just 0.9 [8].

Researchers also put the ceramic coatings through a bunch of heat-ups and cool-downs to see if they could handle sudden temperature changes. Our tests showed they stayed strong and didn't crack or peel off, even after researchers did this a lot of times.[8]

Ceramics face tough times when used in intense conditions. They have some great features, but they're not as strong or tough as carbon fiber composites. These composites are lighter and last longer, which is why cars often use them for parts. They don't rust and can take a lot of hits [1].

3. Aluminum alloys

3.1. Aluminum alloys – specific strength

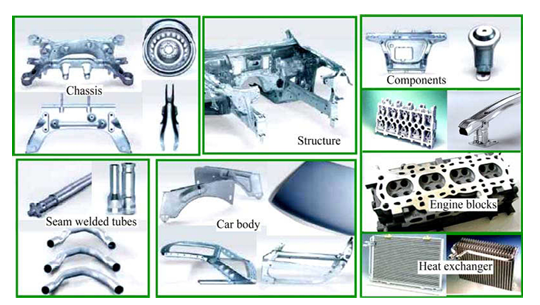

Automotive aluminum alloys are a special class of metallic materials developed to meet the stringent requirements of the modern automotive industry for light weight, high strength and corrosion resistance [11]. By adding elements such as magnesium, silicon, copper and zinc, the tensile strength of these alloys can reach 230-285 MPa, while their elongation is maintained between 19% and 26%, thus significantly improving their mechanical properties and processability, making their application in the automotive industry more and more extensive [Figure 5] [11]. According to different application requirements, automotive aluminum alloys can be divided into two categories: cast and forged, where cast aluminium alloys are mainly used in the manufacture of key components such as engine blocks and wheels, and forged aluminium alloys are mostly used in body structures and interior and exterior panels [Figure 4] [12].

Figure 4: Aluminium products for advanced automotive applications (Hydro) [2]

Aluminum alloys for automotive applications have significant advantages in terms of specific strength and density, but their applications still face some challenges. Aluminum alloys are important materials for lightweight design of automobiles due to their low density (about 2.7 g/cm³) and high specific strength (up to 150 MPa-cm³/g) [13]. However, the brittleness of aluminum alloys increases with increasing specific strength, resulting in insufficient fracture toughness under high stress conditions, a problem that greatly limits the use of aluminum alloys in critical structural components of automobiles [9].SiC and graphite have a great influence on the physical properties of materials, including tribology and mechanics, and therefore, researchers have enhanced the friction properties of their composites by varying their content in aluminum alloys [2].

In the study of aluminium alloys for automotive applications, various modification methods have shown different effects and challenges in the optimisation of specific strength and density. Nanoparticle enhancement techniques have been particularly effective in improving the mechanical properties of aluminium alloys. For example, it was found that by introducing 50 nm Al2O3 nanoparticles, the tensile strength of the material was significantly increased to 515 MPa, which is 47% more than that of conventional aluminium alloys, showing the great potential of nano-strengthening technology [14]. However, this technology also brings with it the issue of increased process complexity, especially in ensuring uniform distribution of nanoparticles and good interfacial bonding, which is a major technical challenge to overcome [14].In contrast, particle reinforcement methods, such as through the addition of silicon carbide (SiC) and alumina (Al2O3) particles, are able to increase the specific strength of aluminium alloys up to 200 MPa-cm³/g, while the density increases only slightly to 2.9 g/cm³ [13]. This approach maintains the relative lightweight advantage of the material while enhancing its specific strength, but there are still limitations in dealing with increased brittleness and improved crack resistance [13]. The use of composites and nanotechnology can increase the mass of aluminum alloys without much change in their density. Therefore, this technology is effective in reducing the weight of the body while improving fuel efficiency and the overall safety of the vehicle [15]. However, the cost and process complexity in practical application are still the key issues restricting its large-scale industrialisation [15].

Figure 5: Difference in surface morphology of different types of textures on aluminium [11]

3.2. Aluminum alloys – corrosion resistance

In recent years, the application of aluminium alloys in the automotive industry has received widespread attention because of its lightweight properties. However, an important problem faced by aluminium alloys in practical applications is their relative lack of corrosion resistance, especially when exposed to corrosive environments such as salt spray, which is prone to corrosion and thus affects their structural integrity and service life [2,16]. Studies have shown that the corrosion resistance of 5xxx and 6xxx series aluminium alloys can be significantly improved by adjusting the alloy composition, especially by controlling the magnesium content. In addition, optimisation of the heat treatment process, such as the use of pre-ageing treatment (preheating to 100°C) during heat treatment, can further refine the microstructure and enhance the corrosion resistance and mechanical properties of the alloy [17]. In the experimental study, by employing various experimental methods such as salt spray testing and fatigue life testing (e.g., measuring the rate of crack extension), the researcher analysed in detail the behaviour of aluminium alloys in corrosive environments.

Figure 6: Stress–strain behaviour of a typical high-strength 6000 series alloy in various ageing conditions [17]

Based on extensive research on aluminium alloys for automotive applications, the results show that the corrosion resistance and fatigue life of aluminium alloys have been significantly improved by optimising the alloy compositions and heat treatment processes. The tests showed that the fatigue life of certain optimised aluminium alloys was increased by more than %30 and the crack extension rate was significantly reduced in a neutral salt spray environment [16]. Meanwhile, the yield strength of 6xxx series aluminium alloys reached over 350 MPa after artificial ageing treatment, while the initial hardness of these alloys increased significantly over a period of weeks during natural ageing [Figure 6] [17]. Furthermore, increasing the magnesium content to 5-6 wt.% can significantly enhance the corrosion resistance of the material while maintaining its high strength [17]. Researchers have found that the right mix of materials, like magnesium and silicon, can make a substance that's both sturdy and doesn't rust easily. If they add a step called "pre-aging" when they heat up aluminum, it becomes more reliable, easier to shape, and lasts longer. The team pointed out that these improvements work well not only in lab tests but also in real-life scenarios. They even discovered how to adjust the heating methods so that the aluminum remains tough and can handle rough treatment, including contact with nasty chemicals. This discovery could be really handy for creating parts for vehicles. All in all, this research supports the idea that tweaking the material mix of aluminum and improving the heating process results in longer-lasting, rust-resistant auto parts. This not only provides a scientific basis for the development of higher performance automotive materials in the future, but also lays a solid foundation for achieving the goals of automotive lightweighting and energy saving and emission reduction [2,17].

4. Titanium alloys

4.1. Titanium alloys – specific strength

Titanium alloys are metal materials formed by combining titanium with other metallic elements such as molybdenum, tantalum, vanadium,manganese, and aluminum [15]. These alloys possess various excellent material properties, including high tensile strength and toughness, lightweight, and great corrosion resistance. 600 MPa to 1,250 MPa is the range of tensile strength of commercially available titanium alloys [18]. Commercially pure titanium exhibits excellent stability at temperatures reaching approximately 300°C, whereas more advanced titanium alloys can retain their exceptional strength even when exposed to temperatures as high as 500°C [Figure 7]. Titanium alloys are widely used in the automotive industry due to their excellent specific strength and resistance to high temperatures. Many motorcycle and car exhaust systems are made of titanium, which can reduce the weight by 3 to 8 kilograms[7]. In terms of improving fuel efficiency, reducing noise emissions, and enhancing power output, the weight reduction effect of engine components is particularly noticeable, especially for engine valves. The use of titanium alloy materials in this field has been quite widespread[7].

In recent years, researchers have challenge of developing a lightweight multi-principal element alloy (LWMPEA) that exhibits both high strength and ductility, while maintaining a low density. The goal is to create an alloy that is suitable for applications in military armor, aerospace and auto application where materials must have high specific strength, good plasticity, and perform well under dynamic, high-strain-rate conditions.

Figure 7: Mechanical properties of titanium alloys [19]

Research show that Ti61Al16Cr10Nb8V5 alloy was created using high-purity raw materials like sponge titanium, aluminum, chromium, niobium, and vanadium [20]. The alloy was melted multiple times in an argon atmosphere to ensure uniformity and was then rolled and annealed to obtain test samples. The dynamic compression experiments with condition of strain rates ranging from 10⁻³/s to 5000/s is conducted on TI61[20]. Precise static tensile and compressive tests were conducted on TI61 to evaluate its performance under both dynamic and static conditions. Electron backscatter diffraction (EBSD), transmission electron microscopy (TEM)and X-ray diffraction (XRD) techniques were used to observe the phase structure and microstructural features of the alloy before and after the tests. [20]. Conventional Ti-BMGs have relatively low glass-forming ability, limiting their application as structural materials and auto application despite their desirable mechanical properties. The researchers alloyed Ti41Zr25Be29Al5 with various percentages of Cu (0%, 2%, 5%, 7%, 9%, 11%) to improve GFA [3]. In the experiment, the strain rate was kept constant at 4×10⁻⁴ s⁻¹ while compressing cylindrical materials with a diameter of 2 mm and a height of 4 mm using a round bar made by arc melting and then cast into a copper mold to form a rod. The structure of the material was analyzed using X-ray diffraction (XRD) and differential scanning calorimetry (DSC), thermal properties, and mechanical behavior [3].

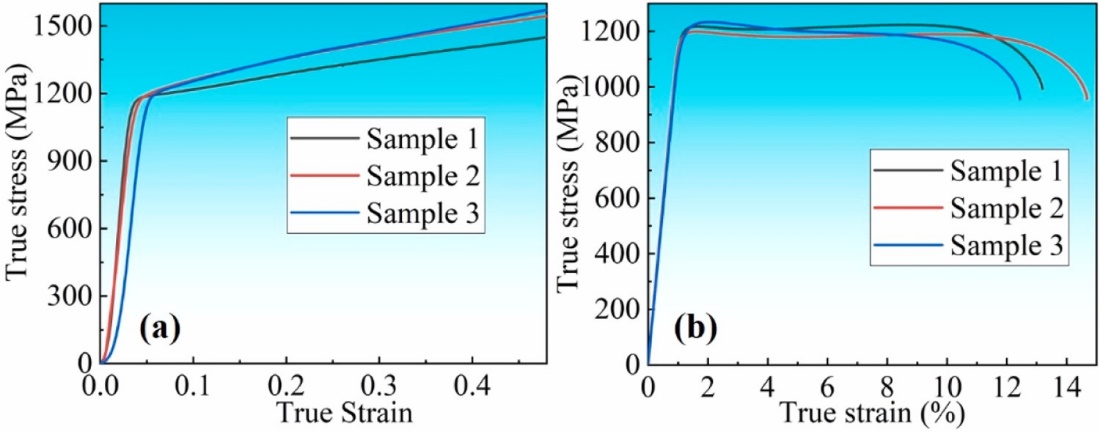

Figure 8: Results of quasi-static tension and compression experiments at room temperature for Ti61Al16Cr10Nb8V5 alloy: (a) compression, (b) tension [20]

Figure 9: Dynamic mechanical properties of Ti61Al16Cr10Nb8V5 alloy: (a) true stress- strain curve of Ti61, (b) SRS of Ti61 [20]

The Ti61 alloy exhibited an ultimate tensile strength of 1223 MPa, a tensile elongation of 13.2%, and an ultra-high specific strength of 253 MPa*cm³/g [Figure 8] [Figure 9]. The dynamic compression test results show that the alloy exhibits a marked strain rate strengthening characteristic. Under low strain rate conditions and high strain rate conditions, its strain rate sensitivity is 0.0087 and 0.0963, respectively. Fracture strains of over 50% were observed, showcasing its excellent ductility under high strain rates [20]. The yield strength of the (Ti41Zr25Be29Al5)91Cu9 alloy was 2092 MPa, and its specific strength was 4.13 × 10⁵ Nm/kg [3]. The addition of Cu not only enhanced GFA but also increased the compressive yield strength and specific strength of the alloy. As the copper content increases, the ductility of the alloy will decrease [3]. Through the research on titanium alloy properties, Ti61Al16Cr10Nb8V5 alloy has superior mechanical properties compared to existing LWMPEAs, this material has significant application prospects in military armor, automotive engineering, and aerospace due to its high specific strength, excellent plasticity, and outstanding performance under dynamic stress conditions.[20]. The observed phase transitions and dynamic recrystallization contribute to its exceptional strain rate strengthening effect, making it highly reliable in high-strain-rate environments such as ballistic impacts and car collision. Due to their low density (5.07 g/cm³) and high strength, Ti-based BMGs offer great advantages in automotive manufacturing [3].

4.2. Titanium alloys – corrosion resistance

Table 1: Densities and mechanical properties of (Ti41Zr25Be29Al5)100xCux (x¼0, 2, 5, 7, 9, 11 at%) BMGs

Composition (at%) | r (g/cm3) | s0.2 (MPa) | smax (MPa) | ep (%) | sp (Nm/kg) |

Ti41Zr25Be29Al5 | 4.8070.01 | 1938 | 2130 | 6.0 | 4.03105 |

(Ti41Zr25Be29Al5)98Cu2 | 4.8670.01 | 2099 | 2154 | 4.1 | 4.32105 |

(Ti41Zr25Be29Al5)95Cu5 | 4.9670.01 | 2093 | 2106 | 1.5 | 4.22105 |

(Ti41Zr25Be29Al5)93Cu7 | 5.0370.01 | 2065 | 2086 | 1.9 | 4.11105 |

(Ti41Zr25Be29Al5)91Cu9 | 5.0770.01 | 2093 | 2209 | 0.6 | 4.13105 |

(Ti41Zr25Be29Al5)89Cu11 | 5.1270.01 | – | 2119 | 0 | 4.14105 |

How Ti-5Al-2V behavior after cold Rotary Swaging (RS) and various annealing processes is not well understood, particularly concerning its corrosion resistance and fatigue performance. The corrosion resistance of Ti-Al-Mo alloys can be compromised due to their microstructure [21]. How to improve corrosion resistance by using rapid solidification to refine the microstructure of alloys? The research focus on corrosion-fatigue strength of Ti-5Al-2V alloy after Rotary Swaging (RS) and annealing and explores the Ti50Al44Mo6 alloy, using rapid solidification via electromagnetic levitation (EML) to control the microstructure through martensitic transformations [22]. The main objective is to impart superior corrosion resistance and mechanical properties to materials through microstructural design [21] [22]. Research indicates that recrystallization annealing can enhance the corrosion resistance of Ti-5Al-2V alloy, while rapid solidification will deepen the intergranular corrosion defects. Ti50Al44Mo6 was rapidly solidified using electromagnetic levitation,which helps in achieving various levels of undercooling. The microstructure and phase transformations were characterized using techniques like EBSD and SEM, and electrochemical corrosion tests were performed in simulated seawater using electrochemical impedance spectroscopy and potential dynamic polarization [21].

The experimental results show an obvious trend that at a low temperature of 233K, the pitting potential of the Ti50Al44Mo6 alloy is raised to 1.034V, indicating that its passivation effect is better, and the corrosion rate is lower [22]. Similarly, the corrosion current density of Ti-5Al-2V alloy was reduced to 0.695 μA/cm² after annealing treatment, indicating a significant improvement in surface stability [21]. The results show that the martensitic phase transition in Ti50Al44Mo6 and the recrystallization process in Ti-5Al-2V enhance the integrity of the passivation layer, indicating that both alloys achieve significant benefits in terms of microstructure refinement, thereby reducing damage due to corrosion. The corrosion resistance of both alloys has been improved, thereby extending the durability of key components such as exhaust systems, engine components, and frames that are often exposed to corrosive environments [21]. The high strength, low-density, corrosion-resistant properties reduce maintenance, extend vehicle life, and improve fuel efficiency, making these materials ideal for the automotive industry, and for automotive applications, these findings offer huge advantages.

5. Carbon fiber

5.1. Carbon fiber – specific strength

Carbon fiber is a high-strength, lightweight fiber material composed of carbon elements, known for its excellent heat resistance, tensile strength, and chemical stability. It is widely used in fields such as aerospace, automotive industry, and sports equipment as a reinforcing material in composite materials.

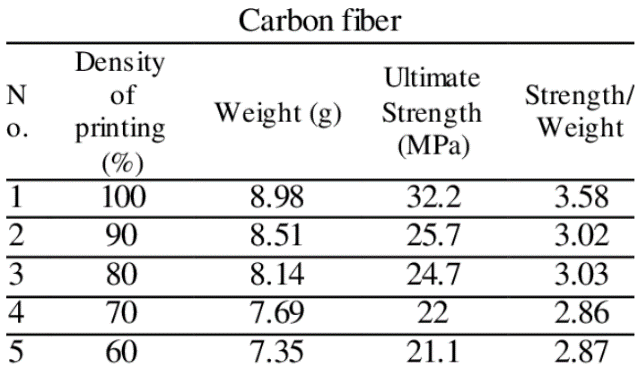

Figure 10: Strength-weight ratio for Carbon fiber specimens [29]

This reduction in mass is concurrent with a proportional decrease in propulsive energy expenditure, indicating that automobiles constructed from carbon fiber materials require less energy input to achieve equivalent performance metrics [24]. The dependent variable, energy consumption, is inextricably linked to the material's density and stiffness, confirming the efficacy of carbon fiber composites [26].

The weight of the vehicle is significantly reduced, with a weight reduction of up to 28% compared to traditional metal structures (Figure 7). The decrease in weight is accompanied by a corresponding decrease in propulsion energy, indicating that vehicles made from carbon fiber require less energy to achieve the same performance level [24]. The dependent variable of energy consumption is closely related to the density and stiffness of the material, confirming the effectiveness of carbon fiber [26].

5.2. Carbon fiber – corrosion resistance

The automotive industry has widely adopted steel and aluminum for their numerous benefits. However, these materials exhibit inadequate performance in high temperatures and corrosive environments, leading to reduced vehicle efficiency and longevity. This also results in increased maintenance costs while compromising fuel economy. [23] To effectively tackle these challenges, carbon fiber composite materials have emerged as a highly promising alternative that offers exceptional resistance against elevated temperatures and corrosion. They ensure structural integrity even in demanding circumstances where metals may face difficulties. Extensive material testing has confirmed the outstanding performance of carbon fiber under such harsh conditions, surpassing the capabilities demonstrated by traditional materials.[25]

Further analysis of the data indicates that carbon fiber composite materials effectively maintain the structural integrity of vehicles, thus preventing any degradation caused by material fatigue or corrosion and ultimately leading to improved fuel efficiency [27]. Long-term monitoring of both fuel efficiency and structural integrity as dependent variables demonstrates that vehicles utilizing carbon fiber composites exhibit significantly better fuel efficiency compared to those constructed with metal, especially in corrosive environments. These observations confirm the exceptional resistance of carbon fiber against degradation, which directly contributes to the long-term performance of vehicles [23].

6. Conclusion

In conclusion, after evaluating the performance of these advanced materials, carbon fiber composites became the best option for automotive engineering due to its excellent performance in all aspects. Other materials such as aluminum alloys, aluminum alloys, titanium alloys and ceramics offer limited advantages, such as high temperature resistance, specific strength, and corrosion resistance, but each face problems including processing complexity, cost and brittleness. Ceramics, despite their resilience to heat and corrosion, are hindered by their brittleness, limiting their use in high-stress automotive components. Aluminum alloys are lightweight and strong but struggle in extreme corrosive environments. Titanium alloys, while offering exceptional strength and corrosion resistance, are prohibitively expensive and challenging to process. On the other hand, carbon fiber composites demonstrate their suitability for automotive engineering due to their high specific strength, excellent corrosion resistance and ability to reduce vehicle weight by up to 28%. Although processing complexities and cost remain concerns, the long-term benefits in fuel efficiency, durability, and performance make carbon fiber composites the most promising material for future automotive applications. Future work should focus on reducing production costs and improving processing techniques to make carbon fiber more accessible for widespread automotive use.

References

[1]. P. Palmero, G. Pulci, F. Marra, T. Valente, and L. Montanaro, "Al2O3/ZrO2/Y3Al5O12 Composites: A High-Temperature Mechanical Characterization," Materials, vol. 8, pp. 611-624, Feb. 2015, doi: 10.3390/ma8020611.

[2]. J. Hirsch, "Recent development in aluminium for automotive applications," Trans. Nonferrous Met. Soc. China, vol. 24, pp. 1995-2002, 2014.

[3]. P. Gong, K.-F. Yao, X. Wang, and Y. Shao, “Centimeter-sized Ti-based bulk metallic glass with high specific strength,” Progress in Natural Science: Materials International, vol. 22, no. 5, pp. 401–406, Oct. 2012, doi: 10.1016/j.pnsc.2012.10.007.

[4]. J. Silvestre, N. Silvestre, and J. de Brito, "An Overview on the Improvement of Mechanical Properties of Ceramics Nanocomposites," Journal of Nanomaterials, vol. 2016, Article ID 106494, 13 pages, 2016, doi: 10.1155/2015/106494.

[5]. W. S. Miller et al., "Recent development in aluminium alloys for the automotive industry," Materials Science and Engineering A, vol. 280, no. 1, pp. 37–49, 2000.

[6]. Q. Sun, G. Zhou, Z. Meng, M. Jain, and X. Su, “An integrated computational materials engineering framework to analyze the failure behaviors of carbon fiber reinforced polymer composites for lightweight vehicle applications,” Composites Science and Techn[ology, vol. 202, p. 108560, Jan. 2021, doi: https://doi.org/10.1016/j.compscitech.2020.108560.

[7]. K. Takahashi, K. Mori, and H. Takebe, “Application of Titanium and its Alloys for Automobile Parts,” MATEC Web Conf., vol. 321, p. 02003, 2020, doi: 10.1051/matecconf/202032102003.

[8]. A. Ayyagari, V. Hasannaeimi, H. S. Grewal, H. Arora, and S. Mukherjee, "Corrosion, Erosion and Wear Behavior of Complex Concentrated Alloys: A Review," Metals, vol. 8, no. 8, Aug. 2018, doi: 10.3390/met8080603.

[9]. F. Hassan, "Aluminum alloys and their classification," J. Mater. Process. Technol., vol. 23, no. 4, pp. 62-73, 1999.

[10]. A. Aguilar-Elguézabal and M. H. Bocanegra-Bernal, “Fracture behaviour of α-Al2O3 ceramics reinforced with a mixture of single-wall and multi-wall carbon nanotubes,” Composites Part B, vol. 42, no. 6, pp. 1282-1289, Aug. 2011, doi: 10.1016/j.compositesb.2011.01.005.

[11]. W. S. Miller, L. Zhuang, J. Bottema, A. J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge, "Recent development in aluminium alloys for the automotive industry," Mater. Sci. Eng. A, vol. 280, no. 1, pp. 37-49, 2000.

[12]. D. V. Ramachandran, "Precipitates in aluminium alloys: their morphology, structural aspects, and significance," J. Mater. Sci., vol. 22, no. 1, pp. 247-251, 2015.

[13]. B. Stojanovic, M. Bukvic, and I. Epler, "Application of aluminum and aluminum alloys in engineering," Applied Engineering Letters, vol. 3, no. 2, pp. 52-62, 2018.

[14]. R. Janjić, M. Bukvić, and B. Stojanović, "Castability and mechanical properties of aluminum alloys," Journal of Materials Engineering, vol. 7, no. 3, pp. 115-123, 2018.

[15]. J. Brown and M. Smith, "Advanced metals for aerospace and automotive use," Materials Science and Engineering, vol. 45, no. 1, pp. 23-37, 2020.

[16]. P. Heuler, "Durability assessment of automotive aluminium parts," Fatigue Fract Eng Mater Struct, vol. 25, pp. 1149-1160, 2002.

[17]. A. Poznak, D. Freiberg, P. Sanders, "Automotive Wrought Aluminium Alloys," in Fundamentals of Aluminium Metallurgy, 2nd ed., Elsevier, 2018, ch. 10, pp. 333-362.

[18]. "Metallurgical Materials Science and Alloy Design - Mechanical Properties of Titanium," Accessed: Aug. 01, 2024. [Online]. Available: http://dx.doi.org/10.1016/j.actamat.2015.06.043

[19]. O. A. Ogunmefun, B. L. Bayode, T. Jamiru, and Peter. A. Olubambi, “A critical review of dispersion strengthened titanium alloy fabricated through spark plasma sintering techniques,” Journal of Alloys and Compounds, vol. 960, p. 170407, Oct. 2023, doi: 10.1016/j.jallcom.2023.170407.

[20]. Y. He et al., “Dynamic mechanical behavior of ultra-high specific strength lightweight Ti61Al16Cr10Nb8V5 multi-principal element alloy,” Journal of Alloys and Compounds, vol. 992, p. 174522, Jul. 2024, doi: 10.1016/j.jallcom.2024.174522.

[21]. Chuvil’deev et al., “Effect of annealing on the corrosion-fatigue strength and hot salt corrosion resistance of fine-grained titanium near-α alloy Ti-5Al-2V obtained using Rotary Swaging,” Journal of Alloys and Compounds, vol. 1003, p. 175612, Oct. 2024, doi: 10.1016/j.jallcom.2024.175612.

[22]. "Enhanced corrosion resistance of Ti-Al-Mo alloy through solid state transformation driven by rapid solidification," Corrosion Communications, Jul. 2024, doi: 10.1016/j.corcom.2023.09.005.

[23]. H. Adam, “Carbon fibre in automotive applications,” Materials & Design, vol. 18, no. 4–6, pp. 349–355, Dec. 1997, doi: https://doi.org/10.1016/s0261-3069(97)00076-9.

[24]. H. T. Sreenivas, N. Krishnamurthy, and G. R. Arpitha, “A comprehensive review on light weight kenaf fiber for automobiles,” International Journal of Lightweight Materials and Manufacture, vol. 3, no. 4, pp. 328–337, Dec. 2020, doi: https://doi.org/10.1016/j.ijlmm.2020.05.003.

[25]. Q. Liu, Y. Lin, Z. Zong, G. Sun, and Q. Li, "Lightweight design of carbon twill weave fabric composite body structure for electric vehicle," *Composite Structures*, vol. 97, pp. 231-238, Nov. 2012. doi: [10.1016/j.compstruct.2012.09.052](http://dx.doi.org/10.1016/j.compstruct.2012.09.052).

[26]. C.Fragassa, A. Pavlovic, and G. Minak, “On the structural behaviour of a CFRP safety cage in a solar powered electric vehicle,” Composite Structures, vol. 252, p. 112698, Nov. 2020, doi: https://doi.org/10.1016/j.compstruct.2020.112698.

[27]. P. Feraboli and A. Masini, "Development of carbon/epoxy structural components for a high performance vehicle," Composites: Part B, vol. 35, no. 4, pp. 323-330, May 2004. doi: 10.1016/j.compositesb.2003.11.010.

Cite this article

Qian,Y.;Zhang,X.;Zhang,Z.;Luo,J. (2025). A Review of Customized Material Properties for Automotive Applications Considering Specific Strength and Corrosion Resistance. Theoretical and Natural Science,107,1-13.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Computing Innovation and Applied Physics

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. P. Palmero, G. Pulci, F. Marra, T. Valente, and L. Montanaro, "Al2O3/ZrO2/Y3Al5O12 Composites: A High-Temperature Mechanical Characterization," Materials, vol. 8, pp. 611-624, Feb. 2015, doi: 10.3390/ma8020611.

[2]. J. Hirsch, "Recent development in aluminium for automotive applications," Trans. Nonferrous Met. Soc. China, vol. 24, pp. 1995-2002, 2014.

[3]. P. Gong, K.-F. Yao, X. Wang, and Y. Shao, “Centimeter-sized Ti-based bulk metallic glass with high specific strength,” Progress in Natural Science: Materials International, vol. 22, no. 5, pp. 401–406, Oct. 2012, doi: 10.1016/j.pnsc.2012.10.007.

[4]. J. Silvestre, N. Silvestre, and J. de Brito, "An Overview on the Improvement of Mechanical Properties of Ceramics Nanocomposites," Journal of Nanomaterials, vol. 2016, Article ID 106494, 13 pages, 2016, doi: 10.1155/2015/106494.

[5]. W. S. Miller et al., "Recent development in aluminium alloys for the automotive industry," Materials Science and Engineering A, vol. 280, no. 1, pp. 37–49, 2000.

[6]. Q. Sun, G. Zhou, Z. Meng, M. Jain, and X. Su, “An integrated computational materials engineering framework to analyze the failure behaviors of carbon fiber reinforced polymer composites for lightweight vehicle applications,” Composites Science and Techn[ology, vol. 202, p. 108560, Jan. 2021, doi: https://doi.org/10.1016/j.compscitech.2020.108560.

[7]. K. Takahashi, K. Mori, and H. Takebe, “Application of Titanium and its Alloys for Automobile Parts,” MATEC Web Conf., vol. 321, p. 02003, 2020, doi: 10.1051/matecconf/202032102003.

[8]. A. Ayyagari, V. Hasannaeimi, H. S. Grewal, H. Arora, and S. Mukherjee, "Corrosion, Erosion and Wear Behavior of Complex Concentrated Alloys: A Review," Metals, vol. 8, no. 8, Aug. 2018, doi: 10.3390/met8080603.

[9]. F. Hassan, "Aluminum alloys and their classification," J. Mater. Process. Technol., vol. 23, no. 4, pp. 62-73, 1999.

[10]. A. Aguilar-Elguézabal and M. H. Bocanegra-Bernal, “Fracture behaviour of α-Al2O3 ceramics reinforced with a mixture of single-wall and multi-wall carbon nanotubes,” Composites Part B, vol. 42, no. 6, pp. 1282-1289, Aug. 2011, doi: 10.1016/j.compositesb.2011.01.005.

[11]. W. S. Miller, L. Zhuang, J. Bottema, A. J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge, "Recent development in aluminium alloys for the automotive industry," Mater. Sci. Eng. A, vol. 280, no. 1, pp. 37-49, 2000.

[12]. D. V. Ramachandran, "Precipitates in aluminium alloys: their morphology, structural aspects, and significance," J. Mater. Sci., vol. 22, no. 1, pp. 247-251, 2015.

[13]. B. Stojanovic, M. Bukvic, and I. Epler, "Application of aluminum and aluminum alloys in engineering," Applied Engineering Letters, vol. 3, no. 2, pp. 52-62, 2018.

[14]. R. Janjić, M. Bukvić, and B. Stojanović, "Castability and mechanical properties of aluminum alloys," Journal of Materials Engineering, vol. 7, no. 3, pp. 115-123, 2018.

[15]. J. Brown and M. Smith, "Advanced metals for aerospace and automotive use," Materials Science and Engineering, vol. 45, no. 1, pp. 23-37, 2020.

[16]. P. Heuler, "Durability assessment of automotive aluminium parts," Fatigue Fract Eng Mater Struct, vol. 25, pp. 1149-1160, 2002.

[17]. A. Poznak, D. Freiberg, P. Sanders, "Automotive Wrought Aluminium Alloys," in Fundamentals of Aluminium Metallurgy, 2nd ed., Elsevier, 2018, ch. 10, pp. 333-362.

[18]. "Metallurgical Materials Science and Alloy Design - Mechanical Properties of Titanium," Accessed: Aug. 01, 2024. [Online]. Available: http://dx.doi.org/10.1016/j.actamat.2015.06.043

[19]. O. A. Ogunmefun, B. L. Bayode, T. Jamiru, and Peter. A. Olubambi, “A critical review of dispersion strengthened titanium alloy fabricated through spark plasma sintering techniques,” Journal of Alloys and Compounds, vol. 960, p. 170407, Oct. 2023, doi: 10.1016/j.jallcom.2023.170407.

[20]. Y. He et al., “Dynamic mechanical behavior of ultra-high specific strength lightweight Ti61Al16Cr10Nb8V5 multi-principal element alloy,” Journal of Alloys and Compounds, vol. 992, p. 174522, Jul. 2024, doi: 10.1016/j.jallcom.2024.174522.

[21]. Chuvil’deev et al., “Effect of annealing on the corrosion-fatigue strength and hot salt corrosion resistance of fine-grained titanium near-α alloy Ti-5Al-2V obtained using Rotary Swaging,” Journal of Alloys and Compounds, vol. 1003, p. 175612, Oct. 2024, doi: 10.1016/j.jallcom.2024.175612.

[22]. "Enhanced corrosion resistance of Ti-Al-Mo alloy through solid state transformation driven by rapid solidification," Corrosion Communications, Jul. 2024, doi: 10.1016/j.corcom.2023.09.005.

[23]. H. Adam, “Carbon fibre in automotive applications,” Materials & Design, vol. 18, no. 4–6, pp. 349–355, Dec. 1997, doi: https://doi.org/10.1016/s0261-3069(97)00076-9.

[24]. H. T. Sreenivas, N. Krishnamurthy, and G. R. Arpitha, “A comprehensive review on light weight kenaf fiber for automobiles,” International Journal of Lightweight Materials and Manufacture, vol. 3, no. 4, pp. 328–337, Dec. 2020, doi: https://doi.org/10.1016/j.ijlmm.2020.05.003.

[25]. Q. Liu, Y. Lin, Z. Zong, G. Sun, and Q. Li, "Lightweight design of carbon twill weave fabric composite body structure for electric vehicle," *Composite Structures*, vol. 97, pp. 231-238, Nov. 2012. doi: [10.1016/j.compstruct.2012.09.052](http://dx.doi.org/10.1016/j.compstruct.2012.09.052).

[26]. C.Fragassa, A. Pavlovic, and G. Minak, “On the structural behaviour of a CFRP safety cage in a solar powered electric vehicle,” Composite Structures, vol. 252, p. 112698, Nov. 2020, doi: https://doi.org/10.1016/j.compstruct.2020.112698.

[27]. P. Feraboli and A. Masini, "Development of carbon/epoxy structural components for a high performance vehicle," Composites: Part B, vol. 35, no. 4, pp. 323-330, May 2004. doi: 10.1016/j.compositesb.2003.11.010.