1. Introduction

Mechanical processing occupies a very important position in China’s industrial production, and it has realized the rapid development and growth of China’s national economy. But the precision of loader machining in China is still in the awkward situation of stopping; therefore, engineers should continue to explore the various factors affecting loader machining in order to improve the quality of workpieces in practice, to provide a strong guarantee for the mechanical processing of China’s loader. The precision of mechanical processing directly affects the quality of the finished products of the mechanical parts of the loader. If the machining precision is not high, it will bring great obstacles to the actual work of the loader and seriously harm the improvement of economic interests. Therefore, in the process of loader machining, engineers should first pay attention to the product quality of parts and constantly improve the accuracy of machining. Many factors determine the machining accuracy of the loader. Obviously, in order to make the quality of loader parts meet the expected requirements, it is necessary to start from all aspects of mechanical processing and strive to improve the machining process and reduce the unqualified rate of loader parts. This paper analyzes the various factors affecting the machining accuracy of the loader and puts forward the specific measures to overcome the problems so as to provide a reference for the practice of loader mechanical engineering.

The machining accuracy of the loader is closely related to the quality of the loader workpiece. Machining mainly for the loader mechanical parts processing, the ideal machining accuracy refers to the finished parts parameters index, mainly in the shape of the parts, size and installation position, etc., the actual parameters and ideal parameters index matching degree is higher, shows that the higher the precision of machining parts, the workpiece quality, the better. In addition, the ideal parameters of all parts of the loader have strict national standards as long as the error within the tolerance standard range meets the requirements. In the machining process, the error is unavoidable because many factors affect the final processing quality of the workpiece. How to make the processing of the workpiece meet the quality requirements and how to reduce the impact of various factors on the processing accuracy has become a thing that must be considered before processing. That is to say, the factors affecting the mechanical processing accuracy must be analyzed.

2. Processed workpieces

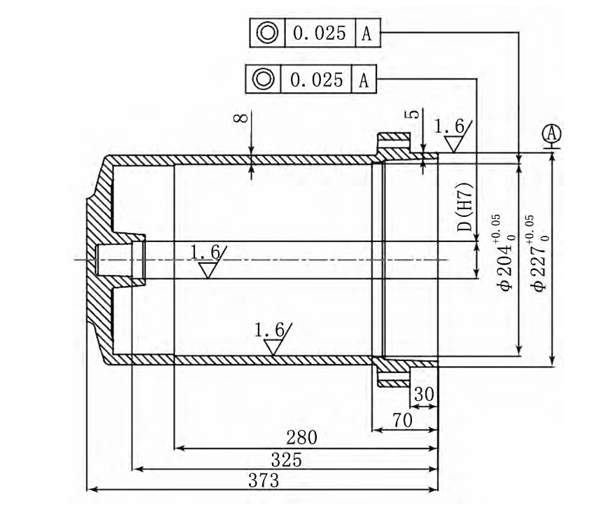

The processing workpiece is, kind of workpiece is a thin wall workpiece; the diameter of the workpiece is greater than 200 mm, the length of the workpiece is about 400 mm, the workpiece wall is relatively thin, and the wall thickness of the port part is only 5 mm. Figure 1 is the schematic diagram of the workpiece structure. The accuracy of the motor shell workpiece has a great impact on the operation efficiency, motor current and noise of the motor, so it has a high requirement for the processing accuracy of the shell workpiece [1]. If the usual processing method is used, it is not easy to achieve the precision requirements of this workpiece processing. Because the number of this batch of processing workpieces undertaken is relatively small, the purchase of high-precision machining equipment or complex fixtures does not meet the economic requirements. Therefore, it is necessary to analyze the factors affecting the processing accuracy of such workpieces, develop more suitable processing technology to ensure that the processing accuracy requirements of workpieces are met, and ensure that the developed processing technology has a good economy as far as possible (Figure 1).

Figure 1. Schematic diagram of machining piece structure (Picture credit: Original)

3. Key influencing factors

3.1. Error in processing principle

In the process of loader machining, the approximate forming motion or the approximate cutting blade form is used to process, which may produce the machining principle error. Here, engineers take the rolling tooth processing as an example. The processing process usually uses the gear hob for processing operation. The gear hob is the source of error. Due to the shortages in the manufacturing process of the involute basic worm, the Archimedes basic worm or the normal straight basic worm can be used to replace it. In order to process the tooth shape into a smooth, gradual line, the outline of the cutting blade is used in practice. Although there is an error in the processing principle, the problem of inadequate teeth of the hob is well solved, and the structure of the machine tool and tool is simplified to a certain extent [2]. Therefore, as long as the processing principle error produced by this method is within the allowable range of processing accuracy, it will become the most efficient processing method and be widely used in the practice of loader machining.

3.2. Spindle rotation error

The machine tool spindle is the most important part of the machine tool system, and the spindle mainly provides the rotating power for the processed workpiece. The workpiece to be processed will be clamped on the spindle of the tool. During the rotation of the spindle, the workpiece is processed. Therefore, the accuracy of the spindle rotation will determine the processing accuracy of the workpiece. That is, the smaller the rotation error of the spindle rotation, the higher the processing accuracy will be. The spindle rotation error mainly comes from the difference or change between the actual rotation axis and the average rotation axis in the rotation process. The error of spindle rotation mainly has three different ways of producing error, such as radial circular beating, axial push and Angle swing. The radial circle beating of the spindle mainly exists in the processing of the outer circle and the inner hole of the workpiece, and the roundness of the outer circle or the inner hole will be directly affected by the radial beating of the spindle [3]. In addition, the error caused by the Angle swing of the spindle is similar to the radial beating, but the Angle swing will also affect the surface cylindrical degree of the machining workpiece. Secondly, the axial movement of the spindle mainly causes the end surface flatness of the workpiece.

3.3. Thermal deformation of the process system

Under the long-term influence of the heat source, the processing system will surely produce different degrees of heat deformation, and the thermal deformation of the processing system will lead to errors in the workpiece processing [4]. The processing materials and processing processes used in different machining links are different, resulting in large differences in the heat source distribution of the processing process. The processing system is deformed due to uneven heating for a long time, which has error effects on the next workpiece processing.

3.3.1. Effect of clamping force deformation on the machining accuracy. In the process of tightening the workpiece, the workpiece will have some deformation under the clamping force, especially for such a thin-wall workpiece. The deformation problem is more serious. The deformation of the clamping force is generally closely related to the specific way and direction of the clamping, and the deformation of the workpiece will also change with the change of the clamping force and will also show strong regular characteristics.

3.3.2. Effect of material stress deformation on workpiece machining accuracy. For the workpiece, in the actual processing process, the distribution of stress in many cases is not uniform, or the stress of the workpiece itself is uneven [5]. After the processing, the stress needs to be balanced again, which may lead to certain deformation of the workpiece. Such precision problems, general and material preparation and molding have a certain correlation. Suppose the uniformity of the material is relatively poor. In that case, the stress deformation is more serious, for example, for some casting workpieces, because in the molding process without uniform heat processing, or some forging pieces not quality processing condition, are prone to stress deformation problems.

3.3.3. Effect of workpiece knife deformation on workpiece machining accuracy. If the processed workpiece of the overall stiffness is not good enough, or the rigid uneven distribution, in the use of clamp damping auxiliary fulcrum is less, easy to make the processed workpiece appear certain knife deformation, and deformation of the knife and cutting force is closely related. The cutting amount and knife actual rate are related [6, 7].

3.4. Positional error

In the process of loader machining, if the adjustment method is used rather than the trial cutting method, the positioning error is mainly apparent by the difference between the positioning benchmark and the design benchmark. There is also a kind of positioning error, that is, the error generated when the spindle is loading the workpiece.

3.5. Tool and fixture manufacturing error

There are many kinds of tools in loader machining. The manufacturing error of ordinary tools has no great impact on the processing accuracy of the workpiece, so the error of the tool manufacturing is mainly present in the fixed size of the tool manufacturing, and the wear of the tool in the use process will also affect the size error of the workpiece. Moreover, if there is a manufacturing error in the fixture, it will lead to the installation of the workpiece on the machine tool, and the inaccurate positioning of the installation position will affect the processing accuracy [6]. In addition, the wear, force deformation and thermal deformation of the fixture will cause the manufacturing error of the fixture.

4. Diverse control methods

4.1. Reduce error directly

Reducing error directly is one of the clearest methods, and it is also one of the most commonly used methods in the general process of error solving; that is, after finding out the cause of the error, engineers can directly propose the solution to the error problem. For example, the long axis turns deformed due to heat. When solving the error caused by the bending of the turning, directly using the reverse cutting method and then applying a spring after the top will directly solve the error problem caused by the thermal deformation of the turning.

4.2. Compensating error

Compensating error is a very clever way to eliminate errors, which can effectively solve many error problems in practice. The error compensation method is to create another new error on the basis of the original error and offset the original error by combining the two kinds of errors [8]. The Error compensation method pursues the principle of positive and negative phase elimination; that is, if the original error is negative, engineers can create another positive error and make the absolute value of the two positive and negative errors equal so as to offset the original error and make the machining accuracy higher.

4.3. Average of the original error

The average of the original error is mainly based on the homogenization of the original error through the trial-cutting process. This method to solve the error mainly focuses on improving the surface accuracy of the workpiece or the precise processing of axes and holes that need perfect coordination. The error homogenization method mainly uses the grinding process and the surface of the workpiece through repeated friction and wear [9]. The basic principle of error elimination is to reduce the error and improve the accuracy by running between two surfaces. It is also a process of mutual inspection, mutual correction and mutual homogenization. This method of eliminating the original error by homogenization is suitable for the processing process of most precision reference parts, which can avoid the adverse effects of the degree conversion error on the machining accuracy to the greatest extent.

4.3.1. Optimizing the workpiece processing process route. The processing workpiece belongs to the casting workpiece. Wool materials used in the process of processing are processed by gravity pouring molding, the specific shape, workpiece performance and processing workpiece for size and location accuracy requirements after a comprehensive analysis. The processing chooses 500 vertical lathes for processing is more appropriate. Processing route is (1) Blank casting processing, (2) Heat treatment, (3) Preparatory treatment, (4) Crude truck processing, (5) Stress time limit releasing, (6) Cargo processing, (7) Drilling and mounting hole machining, (8) The burr processing [10].

4.3.2. Controlling the temperature of the processing. Because the processing of the workpiece belongs to aluminum alloy material, the thermal expansion coefficient of the material is larger; usually, the thermal expansion coefficient is more than 2 times that of the steel material if the temperature value of the processing workpiece changes 2.5 ℃, the diameter of the workpiece will change 0.01 mm, therefore, in the actual processing process, the environment and the temperature of the workpiece itself should be considered. The processing center the process of processing does not have a constant temperature processing working environment, and the processing quantity is relatively small every year. Only processing a batch of workpieces can meet the market for the product demand. Therefore, after communicating with the processor, determined in late October to early November between workpiece processing, the environmental problems can be maintained at around 20 ℃, conforming to the environmental temperature of the workpiece processing.

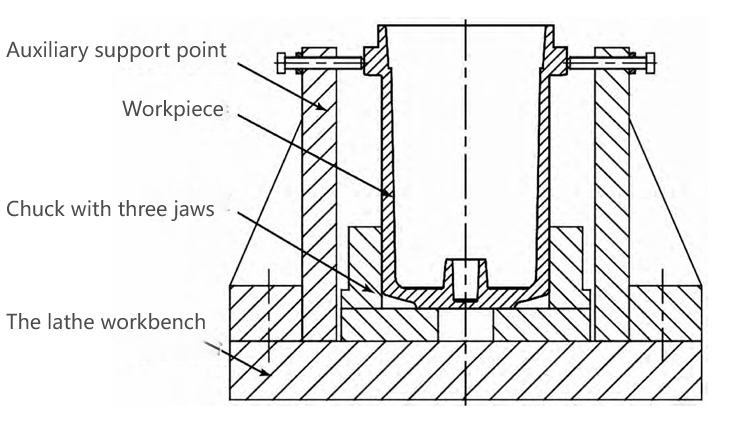

4.3.3. Designing the workpiece machining fixture for optimization and clamping. Because the maximum rotating diameter of the processed workpiece is 270 mm, and the overall length of the workpiece is about 400 mm, the clamping force of the tight part should be fully considered in the design process of the workpiece machining fixture. If the clamping force of the designed clamp is large, it is easy to deform the processed workpiece, and if the clamping force of the designed fixture is small, it is easy to make the workpiece processing loose, which not only may cause the problem of knife collision, but also may lead to the damage of the tool or equipment. Therefore, engineers carried out three rounds of trial production. The designed fixture is shown in Figure 2, and the three claws are used to clamp the bottom position of the workpiece. The holding position is about 50 mm away from the bottom surface, and three auxiliary support points are set at the top position, and the auxiliary support is the active support structure [1]. The fixture effectively solves the contradiction between clamping force and workpiece deformation.

Figure 2. Schematic diagram of fixture (Picture credit: Original)

Because the processed workpiece belongs to the casting part, the external size of the workpiece has a good consistency feature so that it can be used in the process of workpiece positioning. Processing is divided into different processes of rough cars and fine cars. In the process of rough car processing, the set margin is between 0.3 and 0.4 mm. After the completion of rough car processing, the workpiece should be placed in a room temperature environment for more than one day to ensure that the stress in the workpiece can be better released and balanced, and then the fine car processing. Before the finishing operation, the percentage table should be used to ensure that the deviation is controlled within 0.1 mm.

4.3.4. Optimizing the design of the machining fixture. During the processing process of the workpiece, the workpiece processing allowance designed during rough machining is about 3 mm, and there are two feeding operations carried out during the rough machining. The first design cutting depth is 1.8 mm, the set feed amount is 0.25 mm/r, the speed value corresponding to spindle structure is 200 r/min, the designed cutting depth value is 1.2 mm, the set feed amount is 0.3 mm/r, and the corresponding speed value of spindle structure is 25 r/min. In the process of the workpiece, the designed machining allowance is between 0.3 and 0.4 mm, and there are two feeding operations carried out during the refined machining. For the first time, the designed cutting depth is between 0.2 and 0.25 mm, 0.2 mm/r, the corresponding speed value of the spindle structure is 250 r/min, the designed cutting depth is 0.1 mm, the set feed amount is 0.15 mm/r, and the corresponding speed value of the spindle structure is set at 300 r/min.

4.4. Implement real-time compensation control

In the process of loader machining, some machining parts of the machine tool rotation accuracy is quite high; at this time, engineers need to use the compensation control technology. The compensation control technology mainly completes the compensation control by correcting the ruler and receiving the additional moving nut. The accuracy of the correction ruler directly determines the accuracy of the compensation control technology, so the technical difficulty of the compensation control lies in the adjustment of the correction ruler. In practice, software compensation is generally carried out through CNC machine tools [8]. In the processing process, real-time data collection and feedback in the data table for the CNC system to query the error compensation value after completing the precision insertion so as to achieve the purpose of controlling the additional movement of the coordinate axis. The control device is adjusted according to the direction and size of the error data collected in real time.

5. Conclusion

To sum up, the improvement of machining precision plays a key role in improving the quality of products and will affect the reputation and long-term development of the enterprise in the industry. Although there is the possibility of error in mechanical processing, it requires the production personnel to reasonably analyze the actual situation to grasp the causes and laws of the error and, when necessary, apply corresponding measures to improve and improve the production link. Therefore, the author proposed the use of direct reduction of error, compensation or transfer of error and local processing in order to help the production personnel within the allowable range, grasp the accuracy of the mechanical accuracy, and effectively improve the quality of machinery. The corresponding effective measures to remove the error and improve the accuracy are proposed to improve the quality and output of the loader machining.

The influencing factors of machining accuracy are relatively complex, involving human factors, equipment factors and processing process factors. In the industrial development of machining, precision requirements are higher and higher situation. In order to ensure the accuracy of the machining, there is a need to combine the actual equipment and the capital situation, careful analysis influencing factors, not take improvement measures to optimize the processing process, strengthen the worker’s technical skills level, adjust the working state, finally in the controllable scope of improving the processing accuracy as much as possible. At present, there are still many problems in China’s loader machining industry. Therefore, engineers need to explore the root of the problem through continuous practice and sum up more useful processing and production experience.

References

[1]. Yang G 2019 Influencing Factors and Control of Machining Accuracy in Machining 48(12) 84

[2]. Ma P 2015 On the Requirements and Functions of the Protection Device for the Accidental Movement of the Elevator Car 13 8

[3]. Chen J 2017 Discussion on the Causes and Precautions of the Accidental Movement of the Elevator Car 24 46

[4]. He Z 2017 Setting, Inspection and Implementation Mode of the Protection Device for the Accidental Movement of the Elevator Car 13 46

[5]. Li Y 2005 Analysis of the Machining Errors, Xinyu High College Journal 02 1

[6]. Yu Y 2014 Influencing Factors of Machining Accuracy and Ways to Improve Machining Accuracy 02 1

[7]. Liu Q and Wang Q 2017 The Influence of the Machining Process on The Machining Precision of The Parts 18(12) 132

[8]. Zhao L 2019 The Influence of Machining on the Machining Precision of Metal Parts 05 227

[9]. Niu Y 2017 Influencing Factors of Machining Precision and Improving Countermeasures 12 79

[10]. Tian B 2018 Analysis of Influencing Factors and Coping Strategies of Machining Accuracy of Mechanical Parts 24 82

Cite this article

Liu,B. (2023). Impact factors and effective control of machining accuracy in mechanical manufacturing. Theoretical and Natural Science,26,132-138.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Computing Innovation and Applied Physics

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yang G 2019 Influencing Factors and Control of Machining Accuracy in Machining 48(12) 84

[2]. Ma P 2015 On the Requirements and Functions of the Protection Device for the Accidental Movement of the Elevator Car 13 8

[3]. Chen J 2017 Discussion on the Causes and Precautions of the Accidental Movement of the Elevator Car 24 46

[4]. He Z 2017 Setting, Inspection and Implementation Mode of the Protection Device for the Accidental Movement of the Elevator Car 13 46

[5]. Li Y 2005 Analysis of the Machining Errors, Xinyu High College Journal 02 1

[6]. Yu Y 2014 Influencing Factors of Machining Accuracy and Ways to Improve Machining Accuracy 02 1

[7]. Liu Q and Wang Q 2017 The Influence of the Machining Process on The Machining Precision of The Parts 18(12) 132

[8]. Zhao L 2019 The Influence of Machining on the Machining Precision of Metal Parts 05 227

[9]. Niu Y 2017 Influencing Factors of Machining Precision and Improving Countermeasures 12 79

[10]. Tian B 2018 Analysis of Influencing Factors and Coping Strategies of Machining Accuracy of Mechanical Parts 24 82