Bionic Soft Robot Review

Xuyang Gao

Ealing International school, Shenyang, Liaoning Province, China, 110000

xyyy0802@163.com

Abstract. Traditional robots are mainly rigid structures. They are complex in structure but limited in flexibility, and have poor security and adaptability [1]. At that time, many bio-inspired robots were created to overcomethe traditional robotic challenges. Creatures gave us the inspiration to use a soft body to complete task, and then soft robotics were invented. This paper evaluated the future difficulties faced by this area, and listed the deficiencies that still need to be improved for soft robots that should be overcome in future projects as well. First of all, the first difficulty is that most soft robots rely on software drivers to complete tasks, and because of this, the driving functions of soft robots cannot be perfectly performed, and the action tasks are not diverse. Secondly, if the action moving is over flexible, it will be hard to control. The precision for missions cannot be satisfied. Thirdly, the choice of drivers’ type becomes another problem. For example, the memory alloy drive has the advantages of large driving force, controllable stiffness, good elasticity, etc., but it also has disadvantages such as easy aging and slow response speed. Although the pneumatic drive has a fast response rate, there is a risk that the fluid may leak, and the environment cannot be guaranteed to be airtight. Obviously, there is no ideal solution to work out actuation difficulties.

1. Introduction

Nowadays, traditional robots have the disadvantages of complex motion control, high maintenance costs and high costs, which can no longer meet people's living needs, prompting scientific researchers to turn their attention to soft robots[1]. Compare with this, soft robotics have an absolute advantage, which is making interaction with the environment and society safer and more convenient. Thus, it can be widely used for humans and society, such as medicine, health care areas and so on. Soft robots will offer unique properties and, therefore, opportunities that are previously unexplored. Recently, there has been a growing need for devices that can interact with humans such as smart watches and unmanned vehicles. Soft robots are suited for interaction with humans due to their soft and compliant nature and their ability to perform tasks with uncertainties. They minimize damage to the user and the environment via shock-absorbability and are more compatible and reliable with uses regarding biological materials owing to their flexibility. [2]. Easy manipulated, low costs, simple operation principle all belongs to soft robots characteristic better than rigid robotics. In the following part, this paper will first take two examples to display bio-inspired technologies and give a detailed description. Second, this study will introduce various commonly used actuators, related soft materials and their application scenarios. This study demonstrates the current dilemma of soft robots and areas that need improvement, and provides a reference for the development of future soft robots.

2. Analysis of bionic soft robot

2.1. Technology of soft robot in bionic aspect

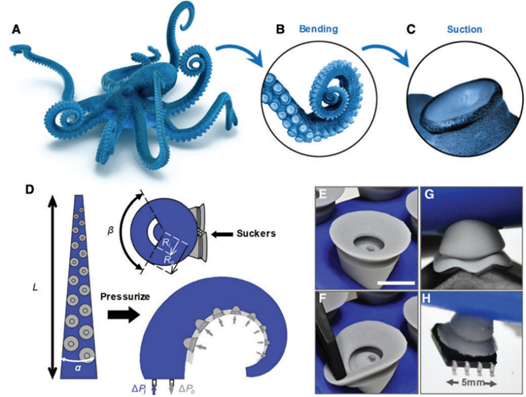

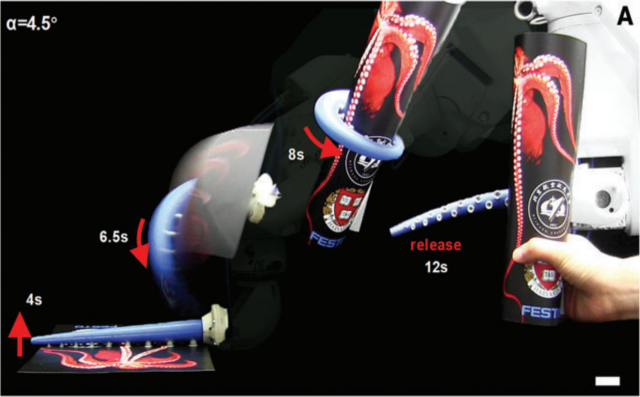

2.1.1. Octopus-inspired soft robotic. Octopus are creatures that live under the sea. In the biological world, it is studied because of its unique appearance and physical function. For example, in the process of grasping an object, the movement is the coordination of eight tentacles. They can effectively catch prey of different shapes and sizes, perform remarkably complex tasks, and retrieve objects from constrained environments by combining two important capabilities: (1) the ability to control many degrees of freedom and (2) the integration of linear arrays of suckers (Fig. 1A–C). Because of their flexibility, agility, and adaptability for efficiently grasping a wide range of structurally diverse objects, octopus’ arms have served as model systems for the development of robust soft robotic prototypes.[3].

Figure 1. Octopus arm-inspired tapered soft actuators with suckers for improved grasping. (A–C) [3].

For designing octopus-inspired soft robot, two characteristics from its body can be utilized from it. (1) Their flexible tentacles can bend at any point, any angle. They can adapt to various shapes of objects, manipulate, and grab them. At the same time, in this process, they apply precise movement and suitable force to control it, so the octopus presents a very soft body and has unlimited degrees of freedom. (2) Another characteristic of its body is the suckers. The octopus uses them to grab, hold and attach to the surface of targets and eat food. [4]. The two features that both help this creature grip objects and are used in soft robots to improve grabbing skills.

Figure 2. Soft robots’ suckers and tentacles.

Figure 3. Octopus-inspired robot manipulation arms.

The octopus-inspired can be seen as a classic example for being inspired by underwater creatures. It represents the specific ability of it, the grabbing skill. In addition, its practical application also showed good results. It can work in tight spaces, move to target locations, and grip objects in narrow slits. Complete the tasks that traditional robots cannot and achieve the purpose of grasping. However, it still has some problem with this technology, that need to be perfected in future designs. I will discuss it in the following section.

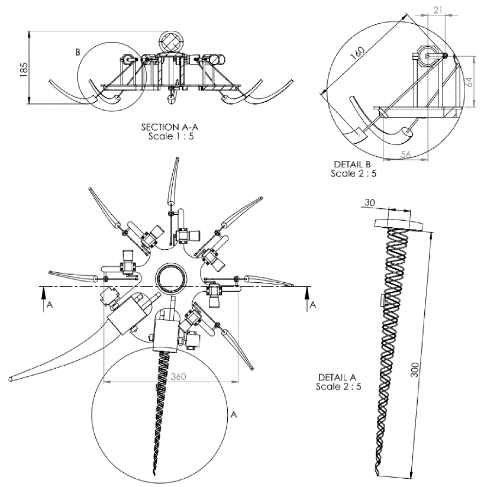

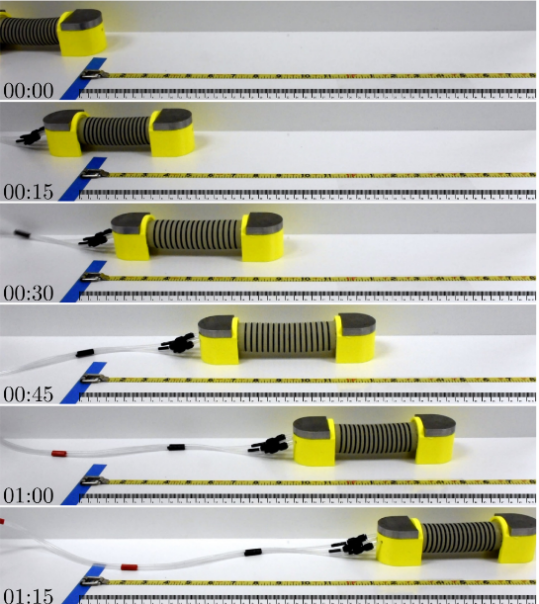

2.1.2. Bionic earthworm crawling robot. The movement of invertebrates is often used as an inspiration for soft robots. Earthworms are a good example, and wriggling is their characteristic mode of movement. Nowadays, there are two types of soft robotics inspired by earthworms: One is varying the stiffness, as animals’ muscles show stiffness changes between passive and active modes. The soft robot can use this kind of technology to apply force and adjust its load capacity, so that it can grab, bend, and move. The other type is achieving crawling motion using different materials to actuate it[5].

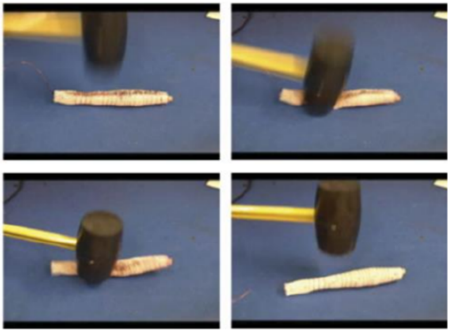

Figure 4. The motion of an earthworm-inspired soft crawling robot as time passed [6].

Most of the research about earthworm-inspired soft robots is dependent on friction on the surface of a crawling plane to crawl. If the frictional force is zero, the robot cannot move. It consists of several modular actuators and works with the coordination of these actuators. The detailed description of actuators will be referred to in the next section.

Another example of an earthworm-inspired soft robot is based on simulating the self-healing function of it. The self-healing function is realized by an alloy material. This shape memory alloy is based on the characteristics of spring and martensitic deformation. The overall structure is composed of a soft mesh material, so it is very resistant to external impact, which also reflects the effect of self-healing.

Figure 5. Test the largest external impact by choosing whole mechanical structure.

2.2. Soft robots’ driver

The software driver mainly works through some movements such as twisting, stretching, stretching, shrinking and other deformation movements. According to different action requirements, the working principle of the driver is different.[7]. The most common are pneumatic actuators, memory alloy actuators, such as shape memory alloys, and new electromagnetic actuators, etc. The following sections will demonstrate the details of these commonly used soft actuators.

2.2.1. Pneumatic actuators. Soft pneumatic actuators (SPAs) used in soft robots are very common. At the same time, it’s widely applied in medical treatment, body wearable devices and so on. The merit of it is that the weight of gas is light, easi to obtain, and cause no pollution. The traditional method to store gas is to use a compressed air pump and make the air flow through it.[8] Furthermore, an attempt to utilize conventional pneumatic artificial muscles (PAMs) has been made. [9]. However, it has disadvantage that it is easily interfere with by other individual units or actuators.

The basic classification of it is two types: positive pressure drivers and negative pressure drivers. By controlling the pressure, the positive pressure mode lets air flow into the enclosure, and the negative pressure mode allows air to flow out of the housing.

Figure 6. Pneumatic soft gripper.

Pneumatic actuation has been applicated to a variety of bio-inspired robots, such as a robot fish, a snake like robot, a manta ray robot, and even a robot partially actuated by internal combustion inside the mold channel for jumping.[10]

The octopus-inspired soft robots also choose pneumatic actuators to drive the body. For example, research done by Harvard University invented a soft robot inspired by the octopus named Octobot. The Octobot moves by pneumatic power: an internal circuit triggers chemical reactions, turning its liquid hydrogen peroxide fuel into a gas, which inflates the robot’s limbs and allows them to move.[11]. Due to its flexibility and quickly responding, so it can complete many complex action tasks, now many soft robots are driven by pneumatics. As for our example 1 mentioned before, it is also utilized pneumatic actuators.

Figure 7. Testing the angle between the actuator and sucker, that almost simultaneous peeling of cylindrical actuator with sucker from a smooth curved plane.

2.2.2. Shape memory material actuator. The shape memory alloys have a wide range of applications, especially in medical and engineering areas.[12] The basic working principle is mainly due to the thermo-elasticity of the material and the mutual transformation between martensite and austenite.[13]. Different types of shape memory alloys depend on various metallic materials to support the function. Some common ones are like Ti-Ni alloy, Cu-AI-Ni alloy, Cu-Zn-AI alloy, etc. [14]. Nonetheless, compared with other alloy materials, Ti-Ni alloys show the best performance in terms of fatigue resistance and biocompatibility. Ti-Ni alloy is also one of the most mature alloy material actuators. Example 2 of the earthworm-like soft robot also uses shape memory alloys as actuators.

Figure 8. Ni-Ti actuator inside the body.

Many of the soft hydrostatic earthworm robot uses silicone to form the main body and are actuated by spring shaped SMA wires.[15]. Body parts are powered by multiple alloy actuators throughout. Although there are some advantages to using SMA such as light weight and high driving force, it still has limitations that limit its performance and application. Its thermal hysteresis makes it difficult to control the actuation. The manufacturing cost is high, and sometimes the lifetime is short.

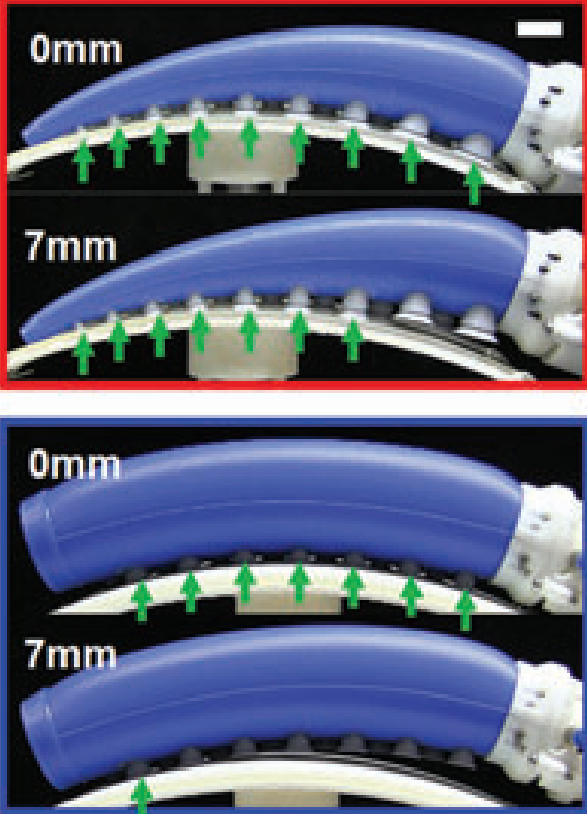

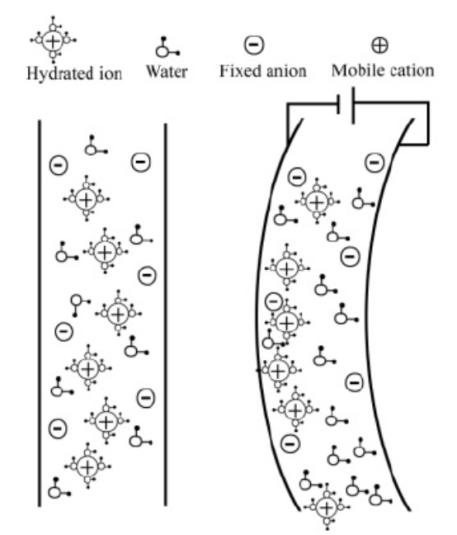

2.2.3. Ionic polymer-metal composite material (IPMC). IPMC is a new intelligent material in recent years. Artificial muscles and robotics actuators often use this kind of stuff. IPMC can stimuli for point-generated mechanical responses that have significant size changes, deformations. [16]. Like memory alloys, ionic polymers are also composed of metal composites, so the choice of metal is particularly important at this time. The most common is perfluoro polymer, and the appropriate material is also selected according to the specific design of the actuators. The mechanism for that is caused by both electrical and chemical properties in ionic polymers, actuated by an electric simulator in wet environment conditions. Its operating mechanism has a sandwich structure for ion exchange with double electrodes on its metal side. When connected to the circuit, the voltage will generate an electric field to drive the cations to deflect, and finally bend towards the anode to achieve the driving effect.

Figure 9. IPMC actuation mechanism.

The IPMC has a fast driving speed, low voltage input requirement, and a large deformable area, so it is widely used as a robot gripper and sensor, especially in soft robot actuators.

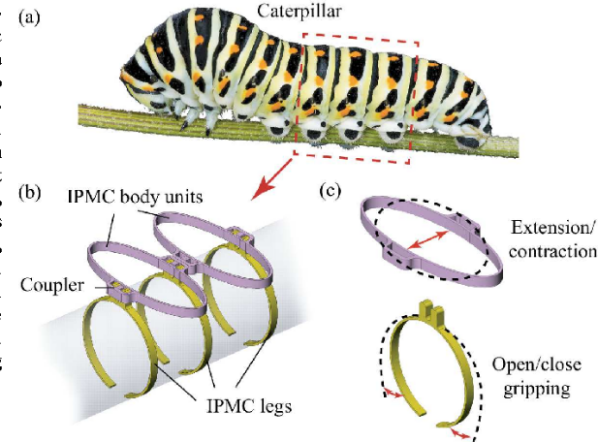

Figure 10. Soft crawling robot with components actuated by IPMC at parts of its body [16].

3. Conclusion

This paper mentions two parts: the first is to illustrate the bionic technology and give a detailed task process; the second is to show the commonly used drives, materials and application scenarios of soft robots. For the two examples, this study mentioned before: octopus-inspired and earthworm-inspired soft robots also have weak points. However, for drivers, there is still a lot of room for problems and improvements that need to be solved. Firstly, most robots rely on software drivers to shrink, bend and other actions, relying on the material characteristics of the actuator. Therefore, the action task that can be completed is very single, which reduces the function of the driver and has not been fully developed. In future experimental research, robots will be paid more attention to the diversity of action. Secondly, to a certain extent, the movement of the software robot is too flexible, and the goals cannot be achieved accurately. In the future, the experimental results must also improve the accuracy of the task and enhance the controllability of the robot, so that it will complete the task accurately and efficiently. The above two points are where the robot drive should be boosted. This essay has a certain one-sidedness and limitations. Future studies and collations will minimize this aspect.

References

[1]. Chu Kaimei, Zhao Hu, Feng Kai, Wu Jie, Zhu Yinlong. Research status of soft bionic robots[J]. Forestry Machinery and Woodworking Equipment, 2021, 49(11):4-10+16. DOI:10.13279/j.cnki.fmwe. 2021.0143.

[2]. Shah, Dylan S. , Powers, Joshua P. , Tilton, Liana G. , Kriegman, Sam, Bongard, Josh, & Kramer-Bottiglio, Rebecca. A soft robot that adapts to environments through shape change. Nature Machine Intelligence, 3 (1). Retrieved from https://par.nsf.gov/biblio/10299026. https://doi.org/10.1038/s42256-020-00263-1.

[3]. Zhexin Xie, August G. Domel, Ning An, Connor Green, Zheyuan Gong, Tianmiao Wang, Elias M. Knubben, James C. Weaver, Katia Bertoldi, and Li Wen. Octopus Arm-Inspired Tapered Soft Actuators with Suckers for Improved Grasping. DOI: 10.1089/soro.2019.0082.

[4]. Joshi, S Y, Singh, S & Deshmukh, S A. Coarse-grained molecular dynamics integrated with convolutional neural network for comparing shapes of temperature sensitive bottlebrushes. npj Comput Mater 8, 45 (2022). https://doi.org/10.1038/s41524-022-00725-7.

[5]. Feng Jiang. Design, manufacture, and control pf a bionic earthworm crawling robot with self-healing function. 10299S1703033. 2020.6.9.

[6]. Ge JZ, Calderón AA, Chang L, Pérez-Arancibia NO. An earthworm-inspired friction-controlled soft robot capable of bidirectional locomotion. Bioinspir Biomim. 2019 Feb 15;14(3):036004. doi: 10.1088/1748-3190/aae7bb. PMID: 30523957.

[7]. Gu Yongxia, Zhou Jianhui, Yin Danni and Zhu Zhihao. A review of research on bionic software drivers. Mechanical Science and Technology. doi: 10.13433/j.cnki.1003-8728.20220112.

[8]. Wang Chengjun, Li Shuai. Research status of software robots [J]. Micro-Nano Electronics Technology, 2019, 56(12): 948-955991.

[9]. Robertson, M A., Sadeghi, H, Florez, J M, & Paik, J (2017). Soft pneumatic actuator fascicles for high force and reliability. Soft robotics, 4(1), 23-32.

[10]. Zaidi, S, Maselli, M, Laschi, C et al. Actuation Technologies for Soft Robot Grippers and Manipulators: A Review. Curr Robot Rep 2, 355–369 (2021). https://doi.org/10.1007/s43154-021-00054-5.

[11]. Laschi, C (2017). Octobot-a robot octopus points the way to soft robotics. IEEE Spectrum, 54(3), 38-43.

[12]. Ostropiko, E, Razov, A, & Cherniavsky, A (2015). Investigation of TiNi shape memory alloy for thermosensitive wire drive. In MATEC Web of Conferences (Vol. 33, p. 03021). EDP Sciences.

[13]. Mirvakili S M, Hunter I W. Artificial Muscles: Mechanisms, Applications, and Challenges.

[14]. Otsuka, K, & Wayman, C M (Eds). (1999). Shape memory materials. Cambridge university press.

[15]. Saito, T, Kagiwada, T and Harada, H. (2009). Development of an Earthworm Robot with a Shape Memory Alloy and Braided Tube. Advanced Robotics, 23, 1743 - 1760.

[16]. Carrico, J D, Kim, K J and Leang, K K (2017). 3D-printed ionic polymer-metal composite soft crawling robot. 2017 IEEE International Conference on Robotics and Automation (ICRA), 4313-4320.

Cite this article

Gao,X. (2023). Bionic Soft Robot Review. Theoretical and Natural Science,2,135-141.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the International Conference on Computing Innovation and Applied Physics (CONF-CIAP 2022)

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Chu Kaimei, Zhao Hu, Feng Kai, Wu Jie, Zhu Yinlong. Research status of soft bionic robots[J]. Forestry Machinery and Woodworking Equipment, 2021, 49(11):4-10+16. DOI:10.13279/j.cnki.fmwe. 2021.0143.

[2]. Shah, Dylan S. , Powers, Joshua P. , Tilton, Liana G. , Kriegman, Sam, Bongard, Josh, & Kramer-Bottiglio, Rebecca. A soft robot that adapts to environments through shape change. Nature Machine Intelligence, 3 (1). Retrieved from https://par.nsf.gov/biblio/10299026. https://doi.org/10.1038/s42256-020-00263-1.

[3]. Zhexin Xie, August G. Domel, Ning An, Connor Green, Zheyuan Gong, Tianmiao Wang, Elias M. Knubben, James C. Weaver, Katia Bertoldi, and Li Wen. Octopus Arm-Inspired Tapered Soft Actuators with Suckers for Improved Grasping. DOI: 10.1089/soro.2019.0082.

[4]. Joshi, S Y, Singh, S & Deshmukh, S A. Coarse-grained molecular dynamics integrated with convolutional neural network for comparing shapes of temperature sensitive bottlebrushes. npj Comput Mater 8, 45 (2022). https://doi.org/10.1038/s41524-022-00725-7.

[5]. Feng Jiang. Design, manufacture, and control pf a bionic earthworm crawling robot with self-healing function. 10299S1703033. 2020.6.9.

[6]. Ge JZ, Calderón AA, Chang L, Pérez-Arancibia NO. An earthworm-inspired friction-controlled soft robot capable of bidirectional locomotion. Bioinspir Biomim. 2019 Feb 15;14(3):036004. doi: 10.1088/1748-3190/aae7bb. PMID: 30523957.

[7]. Gu Yongxia, Zhou Jianhui, Yin Danni and Zhu Zhihao. A review of research on bionic software drivers. Mechanical Science and Technology. doi: 10.13433/j.cnki.1003-8728.20220112.

[8]. Wang Chengjun, Li Shuai. Research status of software robots [J]. Micro-Nano Electronics Technology, 2019, 56(12): 948-955991.

[9]. Robertson, M A., Sadeghi, H, Florez, J M, & Paik, J (2017). Soft pneumatic actuator fascicles for high force and reliability. Soft robotics, 4(1), 23-32.

[10]. Zaidi, S, Maselli, M, Laschi, C et al. Actuation Technologies for Soft Robot Grippers and Manipulators: A Review. Curr Robot Rep 2, 355–369 (2021). https://doi.org/10.1007/s43154-021-00054-5.

[11]. Laschi, C (2017). Octobot-a robot octopus points the way to soft robotics. IEEE Spectrum, 54(3), 38-43.

[12]. Ostropiko, E, Razov, A, & Cherniavsky, A (2015). Investigation of TiNi shape memory alloy for thermosensitive wire drive. In MATEC Web of Conferences (Vol. 33, p. 03021). EDP Sciences.

[13]. Mirvakili S M, Hunter I W. Artificial Muscles: Mechanisms, Applications, and Challenges.

[14]. Otsuka, K, & Wayman, C M (Eds). (1999). Shape memory materials. Cambridge university press.

[15]. Saito, T, Kagiwada, T and Harada, H. (2009). Development of an Earthworm Robot with a Shape Memory Alloy and Braided Tube. Advanced Robotics, 23, 1743 - 1760.

[16]. Carrico, J D, Kim, K J and Leang, K K (2017). 3D-printed ionic polymer-metal composite soft crawling robot. 2017 IEEE International Conference on Robotics and Automation (ICRA), 4313-4320.