1. Introduction

To be a basic technology, inkjet printing technology has arisen the attention of people. Its non-contact printing process which ejects ink droplet directly on the material allows it to be the major image printing method. At the end of 19 century, Lord Rayleigh first introduced the mechanical device that breaks up the stream into small droplets. Until 1951, Elmqvist patented the break-up inkjet mechanism from Rayleigh. After Sweet designed the printing method with continuous ink flow in the early 1960s, IBM licensed and upgrades this technology and applied it to their computer printer, which was known as a continuous inkjet printer [1]. At the same time, Hertz developed continuous inkjet technology for gray-scale inkjet printing. Drop-on-demand inkjet printer was first designed by Zoltan and Kyser and Sear, which was the piezoelectric inkjet technology. In 1979, the other method of drop-on-demand inkjet was invented by Endo and Hara, which was called bubble jet. Based on this method, Hewlett-Packard invented thermal inkjet printers in 1984 [2]. Because of its cheap price, small size, and low noise, thermal inkjet printers are still popular in small business or home printers.

This essay introduced 2 definitions of inkjet printing technology, which are continuous inkjet and drop-on-demand inkjet. For the drop-on-demand inkjet, 4 types of technology are included, which are piezoelectric inkjet, thermal inkjet, electrostatic inkjet and acoustic inkjet. A comparation between continuous inkjet and drop-on-demand inkjet is mentioned in this essay. Moreover, measures to improve the quality of printing are discussed from 3 factors, which are ink, substrate and coffee ring effect.

2. Definitions of inkjet technology

The inkjet technology can be divided into 2 types, the one is continuous inkjet (CIJ), the other is drop-on-demand inkjet (DOD).

2.1. Continuous inkjet printing

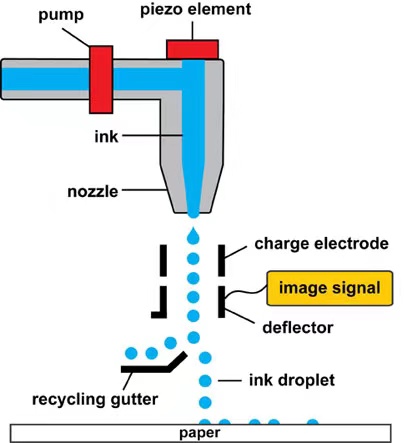

Figure 1 shows the process of continuous inkjet printing. The ink pumped out the ink system is broken into small droplets by the piezo element. Then the droplets will pass through the nozzle and get charged by the charge electrode. When the image signal is sent to the deflector, it will control the voltage of electric field which allows the charged droplets to be deflected and printed on the material. Droplets that have not been charged will be returned to the recycling gutter.

Figure 1: Continuous inkjet printing

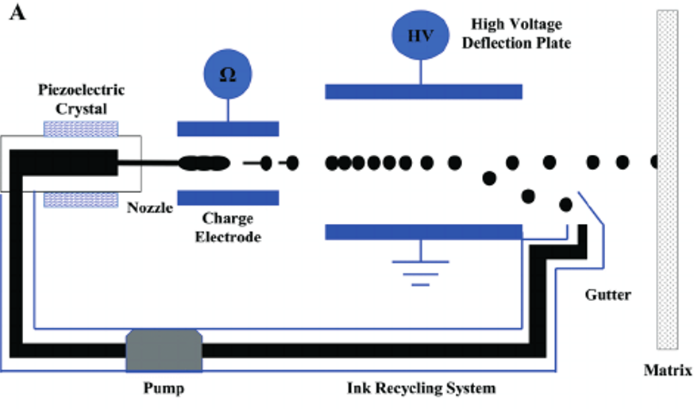

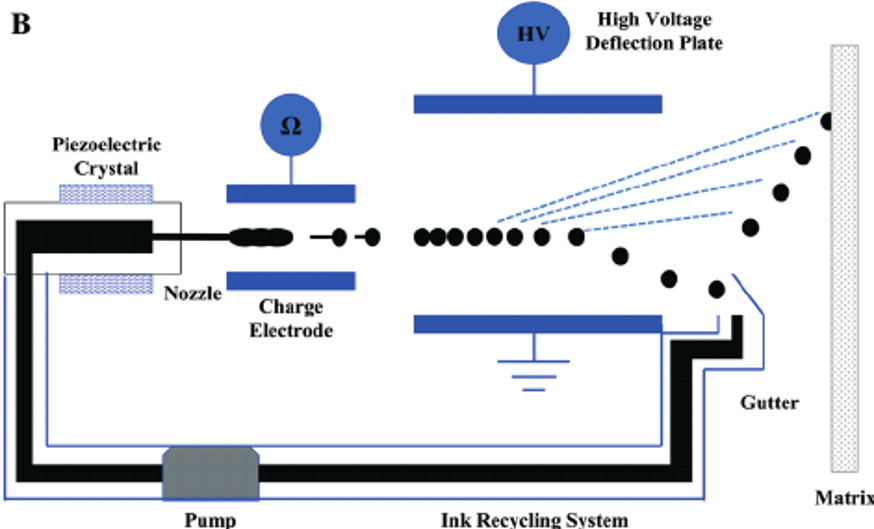

The continuous inkjet can be a binary deflect system or a multiple deflection system. The difference between the two systems is the electrode [3]. Figure 2 displays 2 deflect systems.

Figure 2: 2 types of continuous inkjet printing

A shows the binary deflect system, and B shows the multiple deflect system. In the binary deflect system, the droplet only be charged and fly onto the product directly. However, in a multiple deflect system, the droplets would carry different levels of charges through the electrode. Compared to the binary deflect system, it can print small image with only one nozzle. The working principle of continuous inkjet printing makes its low precision and complicative ink system [1]. However, the high working frequency makes it popular in industrial production.

2.2. Drop-on-demand inkjet printing

Compared to CIJ, DOD printing has a wider range of use, it has been widely used in offices, factories, and people’s houses. It contains 4 types of method, which are piezoelectric inkjet, thermal inkjet, electrostatic inkjet, and acoustic inkjet.

2.2.1. Piezoelectric inkjet printing

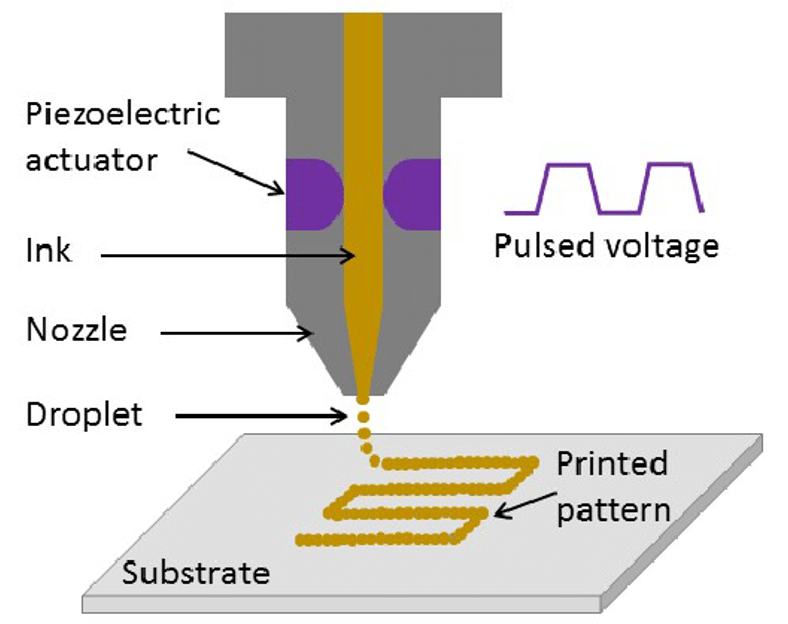

Figure 3 shows the main structure of piezoelectric inkjet printer, which contains the piezoelectric actuator and the nozzle.

Figure 3: The piezoelectric printer

In piezoelectric inkjet printing, a pulsed voltage is applied on the piezoelectric actuator. The piezoelectric actuator will change its shape when a voltage adds to it. This will give pressure to the ink chamber, making the ink droplets eject from the nozzle. In this method, the inkjet can be controlled by the electric system by adding voltage on the piezoelectric transducer.

Before printing, the nozzle will heat the ink into a proper temperature. The viscosity of the ink could be affected by the temperature. The higher the temperature is, the lower the viscosity will be. Thus, piezoelectric inkjet has a significant advantage in maintaining the stability of the ink [4].

Piezoelectric inkjet printing is easy to operate, cost low, and control the droplet in a more accurate way, the inkjet can be directly controlled by applying voltage on the piezoelectric actuator. These advantages allow piezoelectric inkjet printers to be the mainstream printer in the world

2.2.2. Thermal inkjet printing

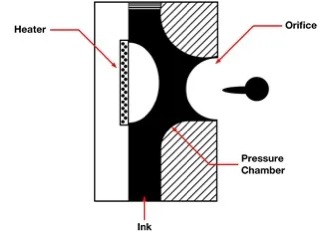

Besides, thermal inkjet printing uses a different method which is shown in Figure 4.. It has 3 forms, roof-shooter, side-shooter, and suspend heater [5]. The orifice of the roof-shooter is located on the top of the heater. In the suspend heater, the heater is suspended in the ink chamber. Differ from roof-heater, the side heater locates its orifice near the heater. Figure 4 shows the form of a side heater. When the heater reaches the temperature which is about 300℃, the time that required it to generate a bubble is only 2 μs. The pressure inside the chamber would increase when the bubble is getting larger, until an ink droplet is ejected though the nozzle. The bubble would break at the same time. The pressure inside the nozzle would decrease because a droplet is ejected. Then the ink would be filled into the ink chamber, which would generate another bubble and form a new droplet. These are the working principles of thermal inkjet printing.

Figure 4: Thermal inkjet printing

The nozzle of thermal inkjet printer is easy to design, and convenient for use. However, requiring for working at a high temperature, the limit for ink that thermal energy is unstable exists. Moreover, high temperatures would lead to chemical change to the ink, which is a disadvantage that cannot be neglected compared to the piezoelectric printing.

2.2.3. Electrostatic inkjet printing

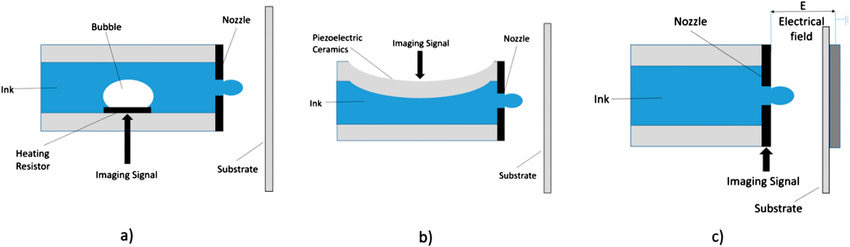

Figure 5 illustrates 3 types of inkjet printing, which includes diagram a for thermal inkjet, diagram b for piezoelectric inkjet, and diagram c for electrostatic inkjet.

Figure 5: 3 types of inkjet printing

Differ from the previous 2 types which push the ink out the nozzle, the electrostatic inkjet uses a charge plate behind the substrate, which creates an electric field between the nozzle and the substrate. The ink droplets will be attracted by the electric force and be pulled to the substrate. The pulsed voltage acting on the charge plate can control the process of ink drop [6].

Compared to piezoelectric inkjet and thermal inkjet, electrostatic inkjet has faster print speed, better print quality, and lower ink consumption. However, the significant limitation of electrostatic inkjet is the property of ink. To be pulled out the nozzle by the electric force, the ink of electrostatic printer must have well electrical conductivity. This restricts the use of electrostatic printing.

2.2.4. Acoustic inkjet printing

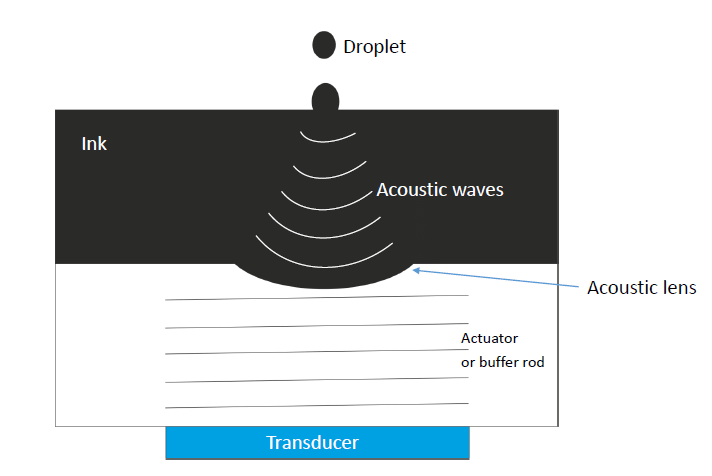

Figure 6 shows the process of acoustic inkjet printing. The working part of the acoustic inkjet printer consists of the transducer and the acoustic lens. The acoustic wave is created by the transducer. When the wave passes through the acoustic lens, it will be focused and burst acoustic energy into one point, which produces and ejects the ink droplet to the substrate.

Figure 6: Acoustic inkjet printing

The acoustic inkjet has its own benefit, which is non-nozzle design. This can extremely avoid the situation of nozzle clogging, which reduces the risk of unexpected failure caused by blocking [7].

2.3. Compare CIJ printing and DOD printing

The difference between CIJ printing and DOD printing depends on the nature of the flow passing through the nozzle. In CIJ printing, the flow of droplets is continuous, the specific droplets that carry charges can pass through the nozzle. In contrast, the flow of DOD printing is impulsive, it only ejects the droplet when needed. Moreover, DOD inkjet produces droplets in the range of 10 to 50 μm, which is comparable to droplets produced by CIJ [8]. These advantages make DOD inkjet have higher precision than CIJ inkjet, allowing it to have better adaptability in different cases.

3. Measures to optimize the precision of inkjet printer

As technology developed, scientists have taken measures to optimize the precision of inkjet printing. The inkjet printing is based on the form, eject, and the drop of every ink droplet. In every term of printing, the droplet experiences ejecting from the nozzle, hitting the base, and spreading out on the surface of the substrate. To optimize the precision of inkjet printer, first is improve the ink.

3.1. Optimize the chemistry component of the ink

The resolution of inkjet printing depends on the depositional area of ink droplets. When the ink droplet drops on the substrate, it will infiltrate and diffuse on the surface of the substrate. The larger the surface leads to the lower resolution. To reduce this area, the viscosity of the ink plays a necessary role, which can restrict the ink from spreading. However, the viscosity of ink cannot be excessively high, otherwise the nozzle would have the risk of being blocked.

L Dybowska-Sarapuk et al. used graphene nanoplatelets(GNPs) which have 10 nm with average thickness and 8 μm with average diameter. They designed an experiment that contains 2 types of the formulations which differ from the adding of commercial polymer dispersing agent [9]. Then the experiment was done at different temperature which was from 15℃ to 45℃. The result is that the viscosity of ink that contains the dispersing agent was lower than the ink that without dispersing agent. In both cases, higher temperatures relate to lower viscosity. Which means the viscosity of the ink can be controlled by temperature.

3.2. Regulate the structure of the substrate

When the droplet infiltrates on the substrate, the depositional area will decrease the resolution. Regulating the structure of the substrate can be a solution.

3.3. Suppress the coffee ring effect

3.3.1. Explanation of the coffee ring effect

When an ink droplet printed on the substrate is allowed to dry, most of the particles will assemble at the edge of the droplet, which forms a ring-like structure. This is called coffee ring effect. The phenomenon is caused by the capillary flow happening in the droplet during the evaporation. When the solvent of the ink is evaporating, the edge of the droplet is pinned on the substrate, while the solvent is flowing from the center to the edge. This makes the solute particles accumulate at the periphery of the drop. The coffee ring effect is one of the most negative factors that affect the quality of inkjet printing.

3.3.2. Suppressions of coffee ring effect

To improve the precision of inkjet printing. Suppressing coffee ring effect is necessary. Contact line pinning and contact angle hysteresis is important in the formation of coffee ring effect.

Cui et al. mitigative the coffee ring effect by using hydro soluble polymer additives. The additive moves the contact line from the viscosity and Marangoni effect. The viscosity provides resistance to the particles, which decreases the number of particles deposited at the edge [10]. Thus mitigates the pinning of contact line. The Marangoni effect leads to the change of the concentration of the polymer at the edge of the droplet while evaporating. This helps with the motion of the contact line.

Commonly, Seo et al. alter the coffee ring effect by using Polyethylene glycol (PEG) to break it and acquire almost uniform deposition of the particles with yielding multi-ring pattern on the droplet area. They use microscopic images and video to observe and analysis the movement and the deposition of the suspended particles in evaporating droplets [11]. They find that the coffee ring effect is altered by PEG which provides surface tension to the droplet and induces a centripetal Marangoni flow.

Soltman and Subramanian set an experiment to test the temperature control of coffee rings. They tested the motion of the drop in different temperatures. They found that when the temperature was rising, the solute in the drop shows a greater transfer to the edge [12]. They used water as the solvent which means the temperature dependence of the surface tension does not need to be considered.

4. Conclusion

This essay introduced the following concept: The inkjet printing technology includes CIJ and DIJ. In CIJ printing, the charged droplet is deflected to the substrate. Compared with binary deflect system, multiple deflect system can print complex image with only one nozzle. CIJ printing has low precision and complex ink system. However, the high working frequency allows it to be used in industrial production. The DOD printing contains 4 types. In piezoelectric inkjet, the piezo actuator will change its shape when receive a voltage signal, thus press the droplet out. Piezoelectric printers are the mainstream DOD printers. In thermal inkjet, the ink is pumped out by the bubble which generated by the heater. Thermal inkjet printer is easy to design and operate. However, temperature is the hardest restriction for it. Electrostatic printer uses a deflect plate under the substrate, which can attract the droplets to the substrate. This method of inkjet has better printing quality. However, the ink must contain electrical conductivity. The acoustic inkjet focuses the acoustic energy to eject the droplets. It can be designed without a nozzle, which reduces the nozzle clogging. The difference between CIJ and DIJ is the nature of the ink flow inside. DOD printing has better precision than CIJ. To optimize the quality of inkjet printing, first is control the viscosity of ink. The viscosity can be controlled by the temperature. Second is adjusting the structure of the substrate. Third is restrain the coffee ring effect. The coffee ring is formed by capillary flow inside the droplet. To suppress the effect, using hydro soluble polymer additives or controlling the temperature can be a solution.

References

[1]. Shah M A, Lee D G, Lee B Y, et al. Classifications and applications of inkjet printing technology: A review. IEEE Access, 2021, 9: 140079-140102.

[2]. Hudd A. Inkjet printing technologies. World Scientific Publishing Co. Pte. Ltd: Singapore, 2010.

[3]. Le H P. Progress and trends in ink-jet printing technology. Journal of imaging science and technology, 1998, 42(1): 49-62.

[4]. Kim J D, Choi J S, Kim B S, et al. Piezoelectric inkjet printing of polymers: Stem cell patterning on polymer substrates. Polymer, 2010, 51(10): 2147-2154.

[5]. Sajedi-Moghaddam A, Rahmanian E, Naseri N. Inkjet-printing technology for supercapacitor application: current state and perspectives. ACS applied materials & interfaces, 2020, 12(31): 34487-34504.

[6]. Schlatter S, Grasso G, Rosset S, et al. Inkjet printing of complex soft machines with densely integrated electrostatic actuators. Advanced Intelligent Systems, 2020, 2(11): 2000136.

[7]. Wijshoff H. Drop dynamics in the inkjet printing process. Current opinion in colloid & interface science, 2018, 36: 20-27.

[8]. Soleimani-Gorgani A. 14.1 Fundamentals of Inkjet Printing Technology 231 14.1. 1 CIJ Printing Systems 232 14.1. 2 Drop on Demand Inkjet Printing Systems 232. 2016.

[9]. Dybowska-Sarapuk L, Kielbasinski K, Arazna A, et al. Efficient inkjet printing of graphene-based elements: Influence of dispersing agent on ink viscosity. Nanomaterials, 2018, 8(8): 602.

[10]. Cui L, Zhang J, Zhang X, et al. Suppression of the coffee ring effect by hydrosoluble polymer additives. ACS applied materials & interfaces, 2012, 4(5): 2775-2780.

[11]. Seo C, Jang D, Chae J, et al. Altering the coffee-ring effect by adding a surfactant-like viscous polymer solution. Scientific reports, 2017, 7(1): 500.

[12]. Soltman D, Subramanian V. Inkjet-printed line morphologies and temperature control of the coffee ring effect. Langmuir, 2008, 24(5): 2224-2231.

Cite this article

Long,S. (2025). A Brief Introduction of Inkjet Printing Technology and Optimizations. Theoretical and Natural Science,80,87-93.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Computing Innovation and Applied Physics

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Shah M A, Lee D G, Lee B Y, et al. Classifications and applications of inkjet printing technology: A review. IEEE Access, 2021, 9: 140079-140102.

[2]. Hudd A. Inkjet printing technologies. World Scientific Publishing Co. Pte. Ltd: Singapore, 2010.

[3]. Le H P. Progress and trends in ink-jet printing technology. Journal of imaging science and technology, 1998, 42(1): 49-62.

[4]. Kim J D, Choi J S, Kim B S, et al. Piezoelectric inkjet printing of polymers: Stem cell patterning on polymer substrates. Polymer, 2010, 51(10): 2147-2154.

[5]. Sajedi-Moghaddam A, Rahmanian E, Naseri N. Inkjet-printing technology for supercapacitor application: current state and perspectives. ACS applied materials & interfaces, 2020, 12(31): 34487-34504.

[6]. Schlatter S, Grasso G, Rosset S, et al. Inkjet printing of complex soft machines with densely integrated electrostatic actuators. Advanced Intelligent Systems, 2020, 2(11): 2000136.

[7]. Wijshoff H. Drop dynamics in the inkjet printing process. Current opinion in colloid & interface science, 2018, 36: 20-27.

[8]. Soleimani-Gorgani A. 14.1 Fundamentals of Inkjet Printing Technology 231 14.1. 1 CIJ Printing Systems 232 14.1. 2 Drop on Demand Inkjet Printing Systems 232. 2016.

[9]. Dybowska-Sarapuk L, Kielbasinski K, Arazna A, et al. Efficient inkjet printing of graphene-based elements: Influence of dispersing agent on ink viscosity. Nanomaterials, 2018, 8(8): 602.

[10]. Cui L, Zhang J, Zhang X, et al. Suppression of the coffee ring effect by hydrosoluble polymer additives. ACS applied materials & interfaces, 2012, 4(5): 2775-2780.

[11]. Seo C, Jang D, Chae J, et al. Altering the coffee-ring effect by adding a surfactant-like viscous polymer solution. Scientific reports, 2017, 7(1): 500.

[12]. Soltman D, Subramanian V. Inkjet-printed line morphologies and temperature control of the coffee ring effect. Langmuir, 2008, 24(5): 2224-2231.