1. Introduction

The growing demand for wearable electronics, human-machine interfaces, and health monitoring systems has driven significant attention toward sensor technologies in recent years [1,2]. Conventional rigid sensors are inherently limited by their restricted stretchability during operation, whereas flexible strain sensors maintain stable electrical and mechanical properties under deformation [3], making them ideal for monitoring complex biomechanical motions and structural health. Among key performance metrics, sensitivity and mechanical strength remain critical challenges impeding their widespread adoption.

Through innovations in material design and structural engineering, researchers have made significant advances in flexible strain sensors. Nanocomposites incorporating carbon nanotubes, graphene, and polydimethylsiloxane (PDMS) demonstrate remarkable sensitivity (gauge factors >100) and broad detection ranges (>50% strain) [4]. Microstructural engineering strategies—including crack propagation designs [5], porous architectures [6], and inspired by kirigami structure configurations [7]—have further enhanced sensing performance by controlling deformation mechanisms. Despite these advances, critical challenges persist in achieving synergistic parameter optimization: most existing designs face unresolved trade-offs between high sensitivity and wide working ranges, while current fabrication methods often lack the scalability required for complex sensor networks, and mechanical strength remains inadequate for practical applications.

To address these limitations, this study employs laser cutting and crack extension techniques to develop a PVA based TA-MXene Janus gradient composite with unique structural configurations, exceptional strength, and high sensitivity. Systematic investigation of crack initiation and propagation mechanisms enables the efficient fabrication of multilayered sensors through laser processing. The optimized sensor exhibits a high tensile strength, ultrafast response time, and broad sensing range, demonstrating reliable performance in diverse scenarios. With its high sensitivity and strain-responsive behavior, the sensor achieves precise human motion recognition, showing promising potential for wearable smart monitoring systems and sports training applications.

2. Experimental

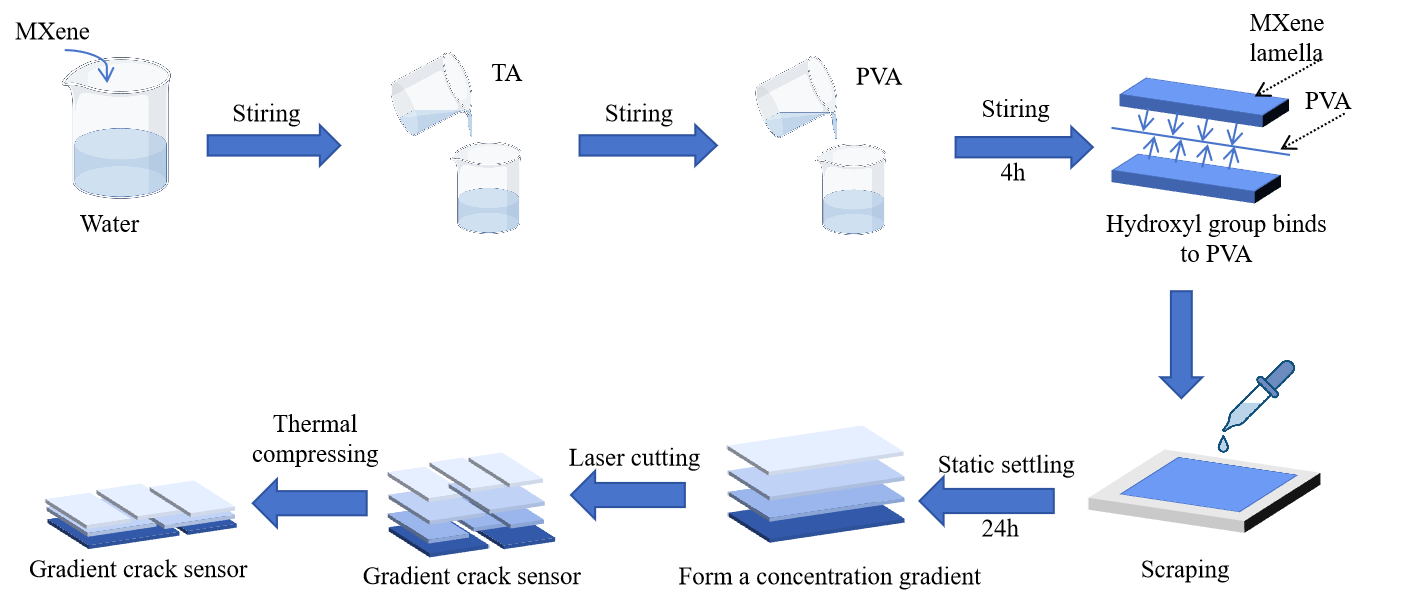

Transition metal carbide (MXenes), polyvinyl alcohol (PVA) and tannic acid (TA) films were prepared as gradient crack sensors by laser cutting, gap coating and thermal pressing process

The preparation process is shown in Figure 1, MXene powder and tannic acid (TA) were added to deionized water, stirred evenly, PVA matrix was added, stirred for 4 h after vacuum defoaming, and films of MXene content of 5wt.%, 15wt.%, 25wt.%, 35wt.% were prepared by gap coating method. The crack structure is prepared in different areas by laser cutting, and then the film is bonded by hot pressing. The MXene powder used in this experiment was purchased from Xianfeng nanometer, the mechanical test, and the electrical characteristics were measured by the digital source table Kethley 34470A, 2450.

3. Results and discussion

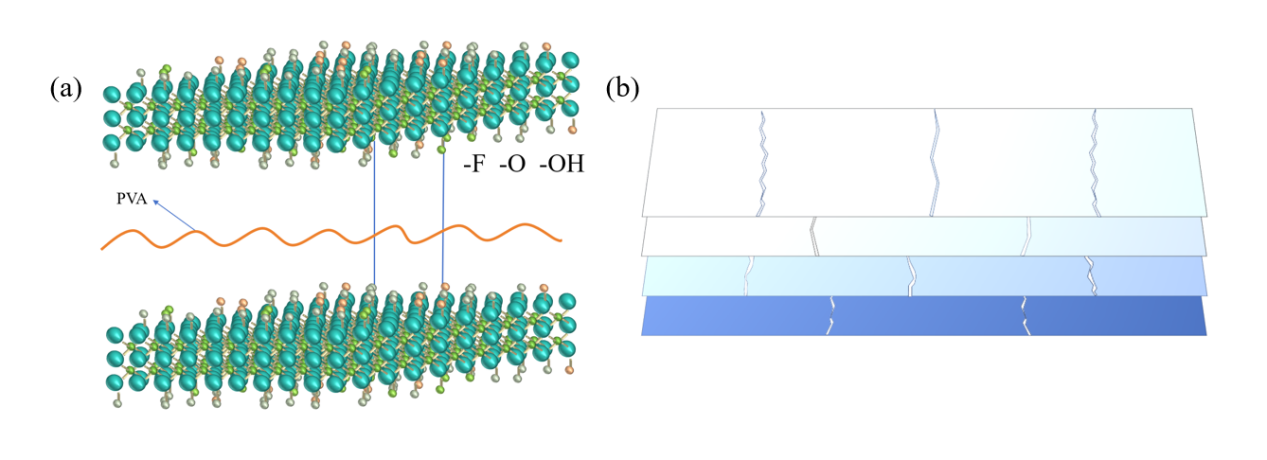

Figure 2a shows the schematic diagram of the microstructure of the PVA-TA-MXenes Janus gradient concentration film prepared by shows. MXene nanosheets (Ti₃C₂Tₓ) are vertically stacked to form a conductive

network and tannic acid molecules cross-link MXene sheets through hydrogen bonds, and the PVA molecular chain is interspersed to form a "bridging structure". Covalent grafting of phenolic hydroxyl on MXene surface at the tannic acid-modified MXene-PVA interface. The two-dimensional properties of MXene lamelayer provides high specific surface area, and π - π stacking of tannic acid suppresses lamelayer stacking and maintains effective conductive pathway. During the tensile strain process, the MXene sheet layer slips, and the tannic acid-PVA dual network dissipates the energy via reversible bonding (hydrogen bond break / recombination).

Figure 2b shows the schematic diagram of the membrane structure mechanism prepared by shows. The sensor is composed of high concentration MXene-TA layer, gradient transition layer and flexible PVA substrate. Laser cutting forms periodic cracks in the MXene layer, and the laser-induced cracks extend vertically within the MXene layer. The brittle fracture of MXene layer works together with the toughness and energy consumption of PVA-TA base to extend the crack extension path and avoid the overall failure of the device. The Janus gradient concentration design realizes the "rigid-flexible" characteristic gradient distribution, coordinating the high sensitivity and large strain compatibility (~400% tensile rate). Laser construction crack network promotion GF. The TA-mediated hydrogen bonding network enhances MXene binding to the PVA interface while providing dynamic energy dissipation mechanisms to avoid crack instability extension. The Janus gradient concentration structure is capable of greatly increasing the sensing range of the strain sensor.

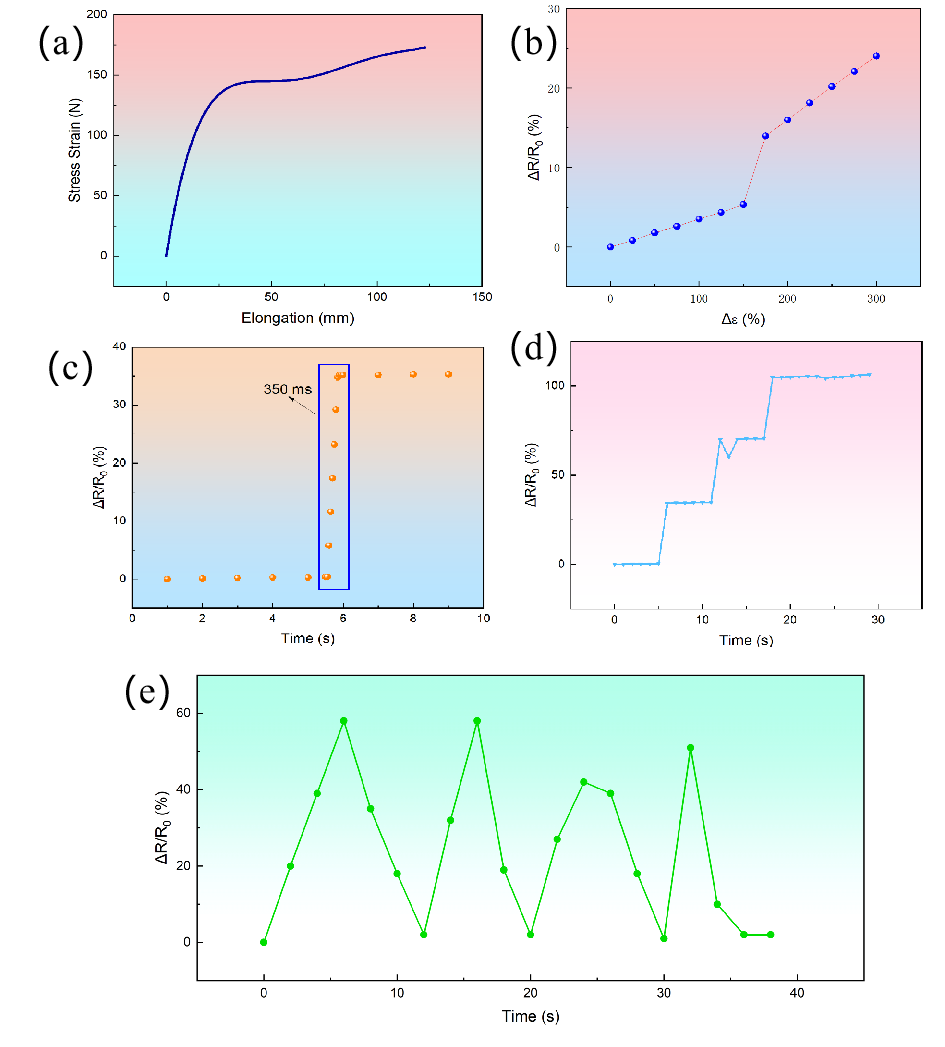

The tensile curve diagram of the film is shown in Figure 3a. As can be seen from the figure, the fracture elongation of the film is 406% and the tensile strength is 11.5 Mpa, which has excellent mechanical properties. The Janus structure mimics the gradient properties of human skin through an asymmetric combination of MXene modified by TA and PVA matrix. This structure can effectively disperse stress concentration and avoid local fracture when stressed. The gradient structure allows the material to show a selective response under abnormal forces (e. g., bending, stretching) , which further enhances the stability of the structure. TA is rich in hydroxyl functional groups, which can serve as a "molecular bridge" between MXene and PVA, forming a strong interface through hydrogen bonds and dynamic covalent bonds: It forms multiple hydrogen bonds with the oxygen-containing functional groups on the MXene surface (such as -OH, -F, -O) and the hydroxyl group of PVA to enhance the interface adhesion force, and delays the crack expansion through the dynamic fracture and redissipation of hydrogen bonds under force. MXene can effectively carry the load when arranged in the tensile direction orientation. The functional groups on the surface of MXene combine the hydroxyl group of PVA through hydrogen bond or van der Waals force to improve the efficiency of interfacial stress transmission. We show that the uniform dispersion of MXene significantly increases the modulus and tensile strength of the composite. As a flexible matrix, the high ductility (pure PVA break elongation can reach more than 300%) of PVA and the rigid complementarity of MXene.

As shown in Figure 3b, which is the rate of the resistance of the film at different strain rates. As you can see from the figure, the prepared film sensitivity (GF) is high, with GF fitting 3.57 from 0 to 150% and 8.06 from 175% to 300%. MXene nanosheets have high conductivity and large specific surface area, which provides the initial high conductivity for the sensor, while its lamellar structure is prone to slip and crack extension under strain, which can lead to significant disruption of the conductive pathway. In addition, PVA, as a flexible matrix, binds to MXene through hydrogen bonding, and its high elastic modulus can effectively transfer the strain to the MXene layer, while inhibiting the overall brittle fracture of the MXene layer. Secondly, the phenolic hydroxyl group in the tannic acid molecule forms a strong hydrogen bond network with the MXene surface functional groups, which enhances the interfacial binding strength of MXene and PVA. This enhanced interfacial effect prefers crack extension to form controllable micro-cracks rather than macroscopic breaks. The synergistic effect of these materials systems enhances the mechanical properties of the films while enhancing the GF. The gradient concentration design of the Janus structure results in differential Young modulus between different layers, creating an interlayer stress gradient upon strain and prompting the preferential nucleation of cracks at the interface. In addition, it was observed that the crack first formed a nanoscale initial crack in the high MXene concentration layer, and the crack gradually expanded to the low concentration layer with increasing strain. This graded extension significantly prolonged the destruction process of the conductive pathway. In addition, the film is preset with a regular crack structure by laser cutting (typical line width 10-50 μm) to maintain its shape during the subsequent thermal pressure (temperature 110℃, pressure 2 MPa). These factors can give the prepared films a high GF.

Figure 3c shows that the response time of thesensor at 10% deformation is around 350 ms. This is because MXene has an extremely high conductivity (~10,000 S/cm) and rich surface functional groups (e. g., -OH, -O), which enables the sensor to quickly adjust the conductive path when strain occurs, realizing the low resistance transmission of electrons inside the material. And the conductivity of MXene mainly depends on the physical contact conductive path, rather than the slow ion migration. When the crack structure is slightly deformed due to strain, the contact resistance between the MXene sheets will change rapidly to achieve rapid electrical signal response. Alternatively, the MXene concentration gradient between the different layers in the Janus structure may lead to a gradient distribution of the mechanical modulus. The higher modulus layer of the upper layer combines with the flexible layer of the lower layer to more efficiently transfer the external strain to the internal conductive network through the "hard-soft" interface during strain. Moreover, the gradient structure may disperse the macroscopic stress to different layers, while the strain in local areas (such as the crack tip) will be amplified, thus accelerating the reconstruction of the conductive network. Due to the predefined crack formed by laser cutting, may occur in strain reversible open / closing behavior, which makes the MXene lamine at the edge of the crack lap state is extremely sensitive to small strain, and multilayer crack structure may gradually strain trigger different depth of crack extension or closure, form a cascade effect, shorten the overall response time. Second, tannins are rich in phenolic hydroxyl groups and may form dynamic hydrogen bonds with the MXene surface functional group or the PVA chain. This reversible bonding can quickly break and recombine during strain, reducing energy dissipation and thus reducing the response delay. And the intercalation of TA can prevent the stacking of MXene, maintain its high specific surface area and active site, and further improve strain sensitivity and response speed.

Figure 3d shows that rate of resistance of the sensor at 10%, 20%, 30%, 40% deformation. As can be seen in the figure, the tensile performance is stable and the response ability is good, which may be due to its multistage structure to guarantee the tensile stability. Firstly, the modulus transition can disperse stress and avoid local failure; secondly, the dynamic crosslinking network formed by PVA/TA can consume energy and suppress crack expansion. In addition, in the multi-layer crack structure, crack layers of different depths are activated step by step during stretching, and stable strain-stress response can be achieved through phased energy dissipation. Finally, the sliding and bridging mechanism of MXene-PVA interface can enhance its balance strength and ductility. In summary, the sensor can achieve stable stretching and impedance change.

Figure 3e shows that the rate of resistance during stretching-unloading of sensor, 25% deformation, at 0.1Hz. In the figure, the resistance shows regular periodic changes and can stabilize stretch-unloading, which is in line with the above advantages of high mechanical strength, high GF and fast response speed.

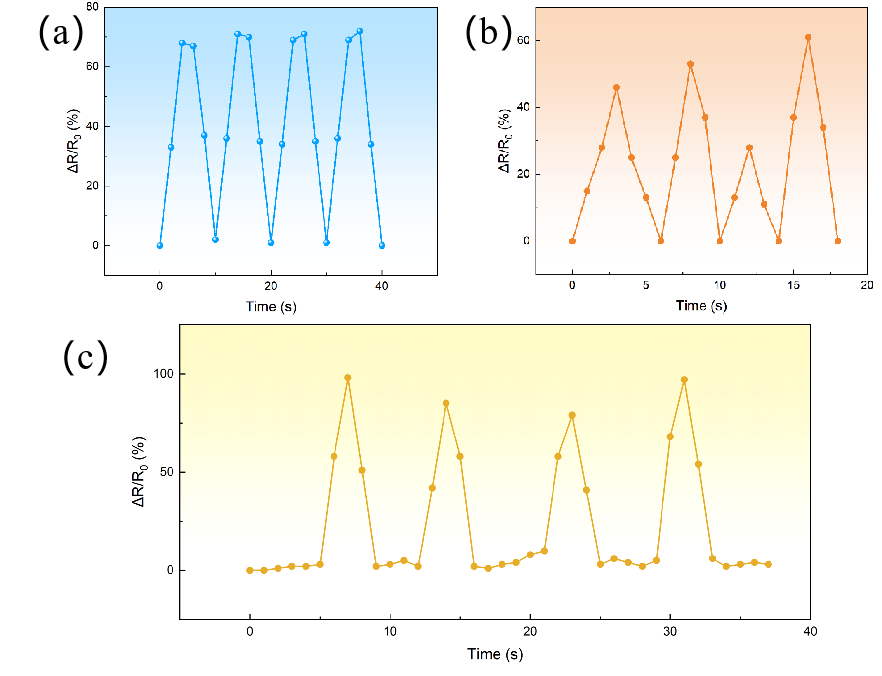

Figure 4a, 4b, 4c show that the rate of change in resistance when the sensor is applied in several common life scenarios. Figure 4a shows the resistance change rate of the sensor for different badminton racket moves on the wrist, and the sensor can be used normally under the tensile strength. Figure 4b shows the resistance change rate of the sensor on the wrist, which shows timely response and high GF for daily use. Figure 4c simulates the resistance change rate. The sensor can stretch and unload, conforming to the advantages of high mechanical strength, high GF and fast response speed. It has the prospect of use in daily life movement.

4. Conclusions

In this paper, we developed a high-performance flexible strain sensor with Janus gradient concentration structure by using the laser forming and thermal pressing process, combining MXene, polyvinyl alcohol (PVA) and tannic acid (TA). The collaborative design of materials, layered structures and manufacturing strategies enables the sensor to achieve high sensitivity (GF>5), strong mechanical properties and rapid response time (350 ms), beyond the limitations of traditional uniform or double-layer structure sensors. Among them, TA, as a molecular adhesive, significantly enhanced the interface adhesion between MXene nanosheets and PVA matrix through hydrogen bond interaction, maintaining the intrinsic conductivity of MXene, while the Janus gradient structure further balanced the mechanical and electrical properties, while achieving high tensile and sensitivity. Alternatively, the laser-induced stratified crack network produced strain-localized conductive pathways. The laser cut-thermal process shows scalable manufacturing potential in crack patterns and interlayer fusion. The process eliminates traditional lithography or solvent-intensive steps, consistent with sustainable, scalable fabrication. The Janus gradient sensor has shown great applicability for real-time monitoring of complex human movements (such as joint flexion) and soft robot technology. It has a broad application prospect in the field of human body monitoring.

References

[1]. Zheng, Y. Q. et al. Monolithic optical microlithography of high-density elastic circuits. Science 373, 88–94 , 2021.

[2]. Zhang, H. et al. Robust self-gated-carriers enabling highly sensitive wearable temperature sensors. Appl. Phys. Rev. 8, 031416 , 2021.

[3]. Jin, Xin, Research Progress in Flexible Wearable Strain Sensors Based on Polydimethylsiloxane, Journal of Materials Engineering, vol. 46, pp. 13-24, 2018.

[4]. Chang, Fuh-Yu, Flexible strain sensors fabricated with carbon nano-tube and carbon nano-fiber composite thin films, vol. 518. Thin solid films, pp.7343-7347, 2010.

[5]. Wang, Rui, Sun, Luanfa, Carbon Nanotube-Based Strain Sensors: Structures, Fabrication, and Applications, vol. 8, Advanced materials technologies, pp. 271–350, Jan. 2023.

[6]. Zheng Shufang, Research progress on graphene/polymer piezoresistive strain sensors with foaming structures, vol. 40, Fine Chemicals, pp. 2597-2608, 2730, Mar. 2024.

[7]. Dijvejin, Zahra Azimi, Kirigami-Enabled Microwave Resonator Arrays for Wireless, Flexible, Passive Strain Sensing, vol. 8, ACS Applied Materials & Interfaces, pp.44256-44264, Sept. 2020.

Cite this article

Feng,J. (2025). Multi-Layered Crack-Like Flexible Strain Sensor with Gradient Concentration Structure Based on Mxene-Ta-Pva. Theoretical and Natural Science,104,19-25.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MPCS 2025 Symposium: Mastering Optimization: Strategies for Maximum Efficiency

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zheng, Y. Q. et al. Monolithic optical microlithography of high-density elastic circuits. Science 373, 88–94 , 2021.

[2]. Zhang, H. et al. Robust self-gated-carriers enabling highly sensitive wearable temperature sensors. Appl. Phys. Rev. 8, 031416 , 2021.

[3]. Jin, Xin, Research Progress in Flexible Wearable Strain Sensors Based on Polydimethylsiloxane, Journal of Materials Engineering, vol. 46, pp. 13-24, 2018.

[4]. Chang, Fuh-Yu, Flexible strain sensors fabricated with carbon nano-tube and carbon nano-fiber composite thin films, vol. 518. Thin solid films, pp.7343-7347, 2010.

[5]. Wang, Rui, Sun, Luanfa, Carbon Nanotube-Based Strain Sensors: Structures, Fabrication, and Applications, vol. 8, Advanced materials technologies, pp. 271–350, Jan. 2023.

[6]. Zheng Shufang, Research progress on graphene/polymer piezoresistive strain sensors with foaming structures, vol. 40, Fine Chemicals, pp. 2597-2608, 2730, Mar. 2024.

[7]. Dijvejin, Zahra Azimi, Kirigami-Enabled Microwave Resonator Arrays for Wireless, Flexible, Passive Strain Sensing, vol. 8, ACS Applied Materials & Interfaces, pp.44256-44264, Sept. 2020.