1. Introduction

China, as the world's dominant apple producer, achieved a record yield of 45 million metric tons in 2021 with sustained growth since 2016 [1]. Apple harvesting, the most critical production link, urgently requires mechanization to reduce economic losses from improper practices. International academic research has focused on harvesting robotics encompassing mechanical design, trajectory planning, target recognition, and grasping control. Pioneering nations, including the United States, France, and Japan, have established theoretical frameworks validated through field prototypes. Israeli firm Tevel's autonomous aerial robot demonstrates 15-hectare orchard coverage with peak-season harvesting capacity for apples and avocados, featuring a compact design for upper canopy access [2]. New Zealand researchers developed a four-armed kiwifruit robot integrating deep learning and stereovision, achieving an 86.0% success rate with a 2.78 s/fruit average picking time. Spain's Agrobot introduced a 24-armed strawberry system using multispectral sensors for real-time fruit analysis [3]. This study presents a design of an apple harvest end effector based on force feedback that combines passive flexibility optimization and active force control. Through theoretical modeling, after designing the bionic manipulator, this study further proposed an intelligent harvesting solution based on morphological adaptation and damage minimization, providing a technical framework for the development of precision agricultural machinery.

2. Actuators design

The end-effector, serving as the actuating mechanism for harvesting operations, constitutes an indispensable component of agricultural harvesting robots. High-performance end-effectors can minimize damage to harvested targets, making their design and optimization a critical research focus in agricultural robotics. In recent years, novel end-effectors for agricultural applications have emerged with advancements in sensor technology and bionic mechanisms, primarily categorized into four types: gripping manipulators, cutting manipulators, pneumatic manipulators, and bionic manipulators [4].

However, the first three configurations exhibit notable operational limitations. Specifically, gripping manipulators may induce mechanical damage to fruit epidermis through direct surface contact, particularly when precise grip force modulation remains unattainable. Pneumatic manipulators face constraints in harvesting efficiency. Enveloping cutting manipulators are susceptible to environmental interference from extraneous botanical elements (e.g., leaves and branches). Consequently, bionic anthropomorphic manipulators demonstrate superior performance characteristics, including strong adaptive capabilities, lightweight design, high stability, and energy efficiency, positioning them as the optimal solution. This configuration leverages biological motion principles to achieve compliant interactions with delicate agricultural products while maintaining operational precision in complex orchard environments.

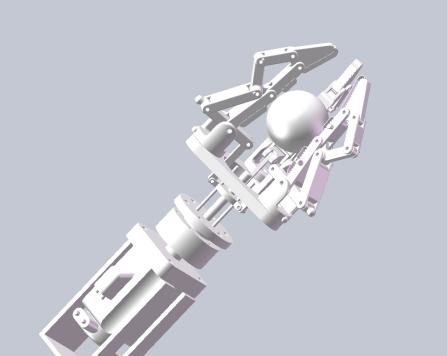

This paper analyzes the motion law of the crank-slider mechanism and proposes a method for achieving energy transfer by using the reverse movement of the crank-slider [5]. During the process of the robot wrapping apples, there are certain requirements for the shape of the fingers so as to ensure successful picking and avoid causing damage to other apples and leaves. Based on the shape of apples, this paper designs the shape of fingers and simulates the process of human hands grasping and putting down apples. An adaptive hand structure of the apple-picking robot was designed, and a three-dimensional model was established, as shown in Figure 1. Each finger of this three-finger manipulator consists of three knuckles. Rubber pads are designed at the fingertips to fix the fruits and prevent the surface of the fruits from being damaged when the manipulator grasps them. The two knuckles below the fingertips are elongated and clamped through the movement of the mechanism.

Therefore, the picking process completed by the mechanical hand is as follows: The motor drives the mechanical arm to approach the target fruit. At this time, the three-finger mechanical hand relaxes and naturally spreads out. The three-finger palm determines through the sensor that the mechanical arm has reached the target position and then clamps the fingers. The motor drives the end effector to rotate and breaks the apple stem. After picking the fruit, the motor reverses, the fingers relax, and the mechanical arm returns to its original position, getting ready for the next grasp.

3. Construction of force-sensing system

3.1. Principle of impedance control

Neville Hogan proposed the anti-control principle in a paper in 1985 [6]. The main idea of this principle originates from the relationship between voltage and current in the circuit system. In a circuit system, when an input voltage is applied across the resistance loop, a current is generated. The ratio of voltage to current is called impedance. Similarly, a mechanical system can also be compared to impedance. When an input force is given to the system, the system will generate corresponding motion. Impedance control is to determine the dynamic relationship between force and position through this method. It provides a control method for a continuous and smooth transition to a specified position, which can be regarded as an instinctive response to the perception of force.

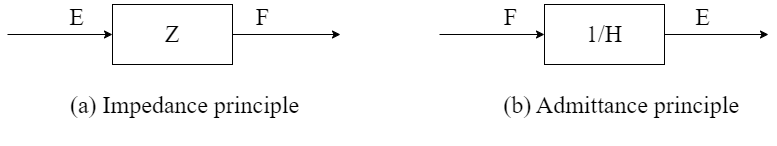

This chapter explores the control strategy of bionic manipulators, enabling the output force of the manipulator to reach the set force quickly and without overshoot during the process of grasping apples. A force output is generated under the action of the position input (Figure 2). This characteristic is called the impedance characteristic, the reverse as admittance property. E represents position deviation, F as force deviation, Z as equivalent impedance, and Z as equivalent admittance.

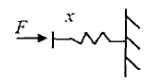

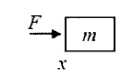

During the contact process, impedance control is manifested in the fact that while the robot performs position control, it also needs to plan its own impedance. In Table 1, for a single-degree-of-freedom system, the impedance model can control the feedback speed or force error by changing the dynamic relationship between force and position to achieve the purpose of compliant control.

|

Model |

F/x |

x/f |

|

||

|

||

|

Impedance control can be represented by a system composed of mass-damping-spring, and its dynamic representation is:

Among them,

Thus, for the mass-damper-spring system, the relationship impedance between its force and displacement can also be expressed as:

For ease of implementation, the expected impedance model is usually represented by a second-order differential equation, and the common form is:

Here,

3.2. Manipulator end grasping control based on position impedance

It is proposed that this approach demonstrates superior stability characteristics compared to alternative methods. The rationale for this preference lies in biomimetic principles derived from human grasping mechanisms. Research indicates that the human hand's adaptive capability to modulate grip forces through haptic feedback constitutes a critical feature for preventing object damage during manipulation tasks. Impedance control emulates this biological strategy by establishing a continuous trajectory modulation framework that facilitates smooth transitional movements toward target positions. This approach can be conceptualized as an engineered analog to biological force-regulation reflexes.

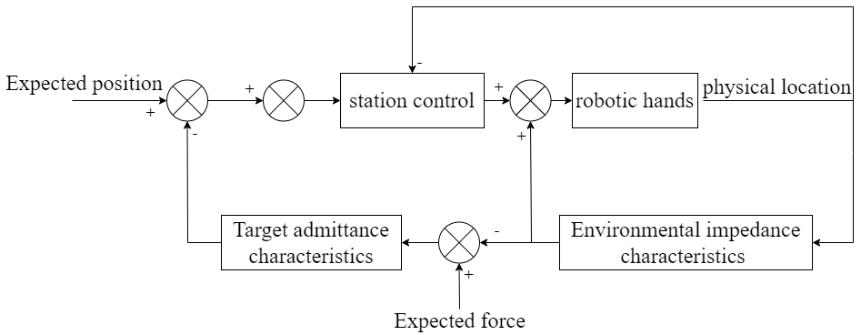

As illustrated in Figure 3, the force-based impedance control paradigm operates through systematic integration of three primary components: desired kinematic states, actual motion parameters, and predefined control objectives. Through computational analysis of these elements, the system derives optimal end-effector contact forces. The control architecture achieves target impedance characteristics through precise force-tracking mechanisms, fundamentally modifying the dynamic coupling between positional motion and force application at the robotic terminal. Consequently, successful implementation of force-based impedance control necessitates comprehensive modeling of the robotic system's anticipated operational states, including both kinematic and dynamic parameters.

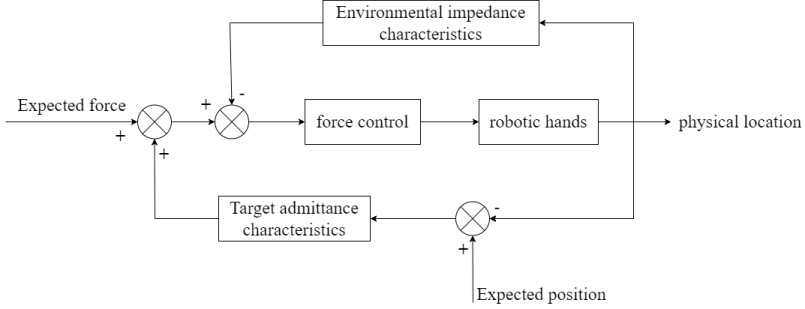

The reactance control mode based on position is composed of the system position control loop and the reactance control loop (Figure 4). Through the deviation of the actual contact force and the expectation force, the method of adjusting the reactance control environment to generate and correct the position shift is used to realize the expected reactance control model. The reactance control model based on position should be used in an unknown environment and have good robustness.

Impedance control in the constrained space can be classified into force-based impedance control and position-based impedance control according to different implementation methods. Force-based impedance control is achieved by solving the expected motion state, the actual motion state, and the parameters of the expected impedance control model to obtain the expected contact force at the end, and by tracking this expected contact force to realize the control of the target impedance model. Its essence is to adjust the dynamic relationship between the force and displacement at the end of the robot. Therefore, when adopting force-based impedance control, it is necessary to clearly define the expected motion state information of the robot.

For the apple-picking manipulator, based on the deviation between the measured force and the preset force, a position-based impedance model controller is input to generate the corrected displacement information of the motor, which then drives the manipulator to grasp the apples.

Position-based impedance control also satisfies formula (4). Substituting

Equation (5) shows the application of the robot impedance control model in the time-domain system, that is, the force-information quantity and displacement quantity change with time. By performing the Laplace transform on Equation (5), its frequency-domain expression can be obtained, and it can be obtained that:

Formula (6) can be understood as the elements in the contact force

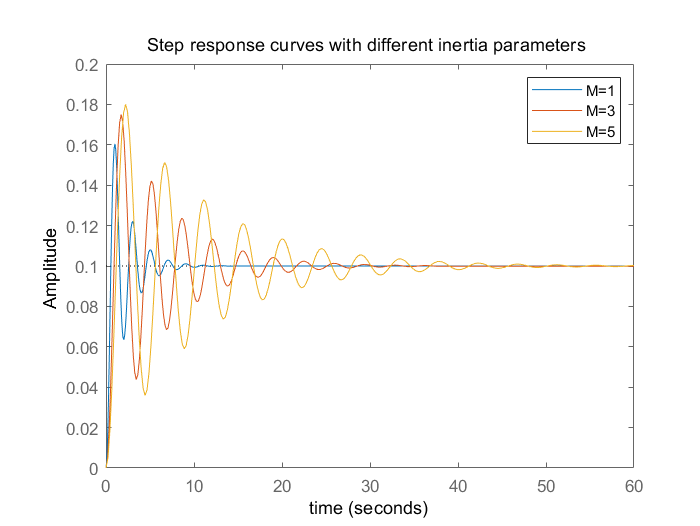

It can be seen that the undamped natural frequency is positively correlated with the target stiffness and negatively correlated with the target inertia. The damping ratio is negatively correlated with the target stiffness and target inertia and positively correlated with the target damping. Within a certain range, increasing the target stiffness can raise the natural frequency and enhance the response speed of the system. However, it simultaneously reduces the damping ratio, which will weaken the oscillation performance of the system. If the stiffness is too large, the system will become unstable. Therefore, it is necessary to select appropriate impedance parameters in order to design a target impedance model with good performance.

When the end of the picking manipulator comes into contact with the apple, the system will generate a certain impact force due to inertia, which may have a certain impact on the stability of the entire system. Therefore, it is necessary to set reasonable adjustment target impedance parameters. To select reasonable impedance control parameters, this paper analyzes the impact of impedance parameter changes on the system one by one, as follows:

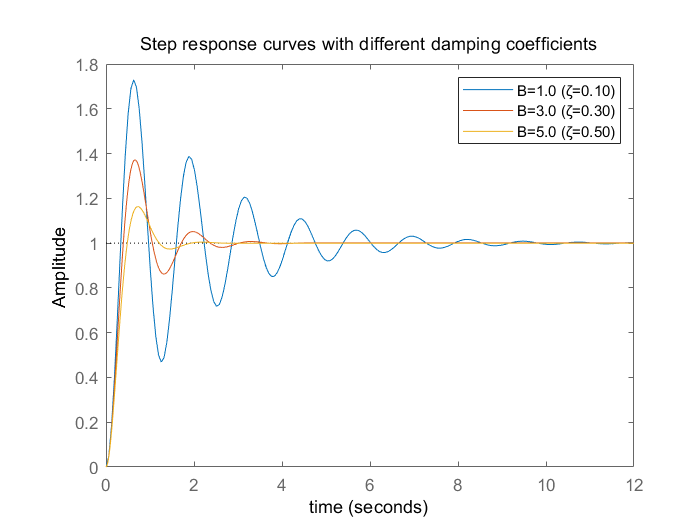

In Figure 5, the change in the value of the inertia parameter

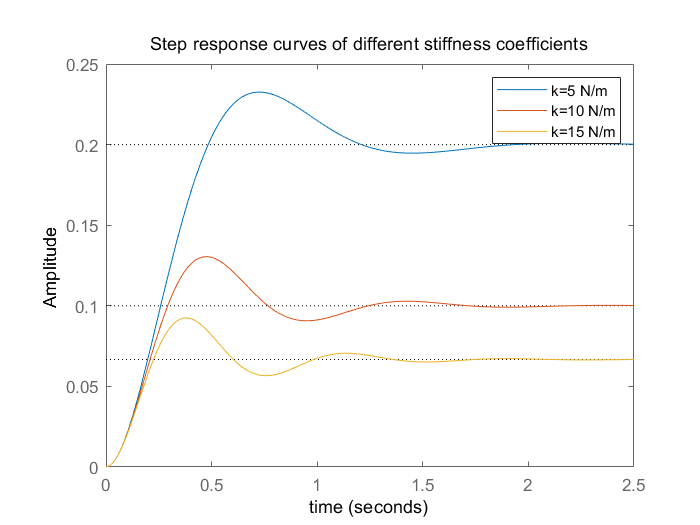

Figure 6 shows the displacement correction response curve obtained by only changing the value of

From the simulation results, it can be seen that the functions of the impedance parameters

3.3. Improved grasping control based on position impedance

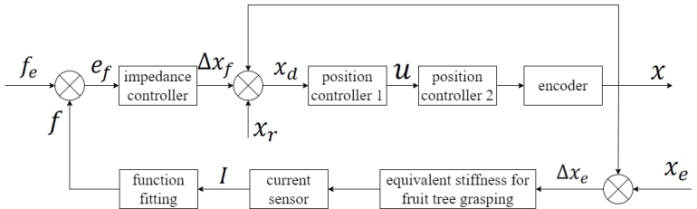

Zhong and others from Nanjing Agricultural University arranged force sensors on the mechanical hand device and combined them with current sensors [8]. They used current signals to replace force signals and designed a position-based impedance control block diagram (See Figure 8):

Among them,

During the grasping process implemented by Zhong's team using the impedance control method they designed, the deviation between the measured force and the given force was measured. Only in a few grasping attempts did the relative error between the two exceed 10%, with an average error of around 4%. From this, it can be concluded that the improved impedance control basically meets the requirements of the picking robot for grasping force control. After reaching the target position, the mechanical hand can stably complete the grasping task. After the above multiple grasps, the success rate is above 94%, so the success rate of the entire system is relatively high, and it can complete the picking task as expected.

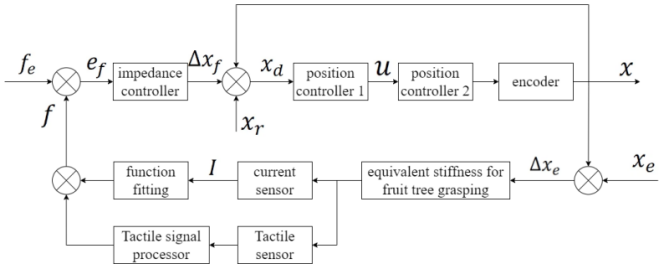

The current sensor is installed on the surface of the manipulator, which will not change the structure of the manipulator and reduces the design difficulty. Therefore, the Hall principle of the current sensor is utilized to measure the current value of the drive motor. Compared with the force sensor, its advantages are very prominent. In addition, the tactile sensor can not only precisely grasp and effectively reduce fruit damage but also adapt to complex environments [9]. Therefore, in this study, a certain number of tactile sensors were arranged based on Zhong Hongyu's work. The improved impedance control diagram is shown in Figure 9:

4. Other approaches

Yang’s team from Shandong Agricultural University proposed to train the grasping action compensation model by using Support Vector Classification in Support Vector Machine (SVM) [10]. This model can classify the grasping state based on the current reading of the pressure sensor and compensate for the grasping action according to different grasping states. The training of the SVM model is based on a large amount of experimental data, including the readings of the pressure sensor under different grasping actions and their corresponding grasping states, providing data support for precise control. Then integrate the trained SVM model into the MPC framework. The controller compensates for the picking position of the picking manipulator in real time based on the prediction results of the SVM model, ensuring the stability and success rate of grasping. By using the MPC control strategy integrated with the SVM model, the system can not only operate stably in a complex working environment but also flexibly adjust the control strategy based on real-time data and prediction results to ensure the lossless grasping of apples during the picking process.

5. Conclusion

This paper aims to develop an apple-picking manipulator. This manipulator does not require multi-threading control like traditional rigid manipulators and can achieve non-destructive grasping of the grasping target, which is of great significance for promoting agricultural automated picking operations. Therefore, this paper addresses the problems of low recognition accuracy, obstacle obstruction, and easy damage to apples in the intelligent apple picking process. It analyzes the basic parameters such as the apple picking process and mechanical properties. Based on the experience of manual apple picking, an apple picking manipulator with a force-sensing control system is designed. In addition, this paper also introduces the basic principle and application scenarios of the impedance control algorithm. A second-order impedance controller is established for the contact problem between the manipulator and the apple. A double closed-loop PID control system with force feedback as the outer loop and position quantity as the inner loop is constructed. In the force feedback, a force fusion module is designed, and tactile sensors and current sensors are used to improve the accuracy and efficiency of feedback. In the issue of obtaining the magnitude of the feedback force, the functional relationship between the finger contact force and the current is determined by using the curve fitting of the least square method. The input of the PI position controller is adjusted through the output of the impedance controller to complete the closed-loop control. Finally, analyze the influence of the changes in the parameters of the impedance controller on the system one by one. Although the design results have not been verified, further data collection and experiments will be carried out in the future to verify the feasibility of the control process.

References

[1]. China Apple Industry Association, and China Agricultural University Agricultural Planning and Design Institute. "2021 China Apple Industry Development Report (General Edition) Condensed Version." Chinese fruits and vegetables 43.01(2023): 1-8. doi: 10.19590/j.cnki.1008-1038.2023.01.001

[2]. Bao Weijia, Peng Lirong, Wang Wenjing, et al. The Application and Development of Agricultural Information Technology in Agricultural Robots [J]. Agricultural Technology Service, 2025, 42(04): 85-91.

[3]. Ou Jun, Ning Feng, Cheng Biyi, et al. Research Progress and Prospect of Key Technologies of Fruit Picking Robot Based on Visual Recognition [J]. Agricultural Equipment and Vehicle Engineering, 2020, 63(05): 16-23.

[4]. Zhao Chunguang Design and Optimization of Apple Picking Manipulator [D]. Harbin University of Commerce, 2020.

[5]. Zhang Chenhe A kind of apple picking machine design and research. 2020. Chengdu university, MA thesis. Doi: 10.27917 /, dc nki. Gcxdy. 2020.000083.

[6]. Neville Hogan. Impedance control of industrial robots [J]. Robotics and Computer IntegratedManufacturing, 1984, 33(2): 97-113.

[7]. Liu Qi. Soft underwater manipulator control method research [D]. Huazhong university of science and technology, 2021. The DOI: 10.27157 /, dc nki. Ghzku. 2021.004811.Williams H, Ting C, Nejati M, et al. Improvements to and large-scale evaluation of a robotic kiwifruit harvester [J]. Journal of Field Robotics, 2020, 37(2): 187-201

[8]. Zhong Hongyu Apple picking software design and control of the manipulator system research [D]. Nanjing agricultural university, 2020. The DOI: 10.27244 /, dc nki. Gnjnu. 2020.001283.Altaheri H, Alsulaiman M, Muhammad G. Date Fruit Classification for Robotic Harvesting in a Natural Environment Using Deep Learning [J]. IEEE Access, 2019, 7: 117115-117133.

[9]. Yan Zhenghong, Guo Yidan, and Chen Lin." Research on Feature Extraction and Processing of Tactile Information in Picking Robots." Journal of Xinxiang University 39.06(2022): 36-39.

[10]. Yang Huawei Key techniques of intelligent short anvil dense planting apple orchard picking. 2024. The shandong agricultural university, PhD dissertation. The doi: 10.27277 /, dc nki. Gsdnu. 2024.001346.

Cite this article

Huang,X. (2025). Research on Force-Sensing Control System of Apple Picking Robotic Hand. Theoretical and Natural Science,134,44-54.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-APMM 2025 Symposium: Controlling Robotic Manipulator Using PWM Signals with Microcontrollers

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. China Apple Industry Association, and China Agricultural University Agricultural Planning and Design Institute. "2021 China Apple Industry Development Report (General Edition) Condensed Version." Chinese fruits and vegetables 43.01(2023): 1-8. doi: 10.19590/j.cnki.1008-1038.2023.01.001

[2]. Bao Weijia, Peng Lirong, Wang Wenjing, et al. The Application and Development of Agricultural Information Technology in Agricultural Robots [J]. Agricultural Technology Service, 2025, 42(04): 85-91.

[3]. Ou Jun, Ning Feng, Cheng Biyi, et al. Research Progress and Prospect of Key Technologies of Fruit Picking Robot Based on Visual Recognition [J]. Agricultural Equipment and Vehicle Engineering, 2020, 63(05): 16-23.

[4]. Zhao Chunguang Design and Optimization of Apple Picking Manipulator [D]. Harbin University of Commerce, 2020.

[5]. Zhang Chenhe A kind of apple picking machine design and research. 2020. Chengdu university, MA thesis. Doi: 10.27917 /, dc nki. Gcxdy. 2020.000083.

[6]. Neville Hogan. Impedance control of industrial robots [J]. Robotics and Computer IntegratedManufacturing, 1984, 33(2): 97-113.

[7]. Liu Qi. Soft underwater manipulator control method research [D]. Huazhong university of science and technology, 2021. The DOI: 10.27157 /, dc nki. Ghzku. 2021.004811.Williams H, Ting C, Nejati M, et al. Improvements to and large-scale evaluation of a robotic kiwifruit harvester [J]. Journal of Field Robotics, 2020, 37(2): 187-201

[8]. Zhong Hongyu Apple picking software design and control of the manipulator system research [D]. Nanjing agricultural university, 2020. The DOI: 10.27244 /, dc nki. Gnjnu. 2020.001283.Altaheri H, Alsulaiman M, Muhammad G. Date Fruit Classification for Robotic Harvesting in a Natural Environment Using Deep Learning [J]. IEEE Access, 2019, 7: 117115-117133.

[9]. Yan Zhenghong, Guo Yidan, and Chen Lin." Research on Feature Extraction and Processing of Tactile Information in Picking Robots." Journal of Xinxiang University 39.06(2022): 36-39.

[10]. Yang Huawei Key techniques of intelligent short anvil dense planting apple orchard picking. 2024. The shandong agricultural university, PhD dissertation. The doi: 10.27277 /, dc nki. Gsdnu. 2024.001346.