Comparative Study On The Performance of Traditional Engines and Hybrid Engines

Yijia Sun

Mechanical Engineering, Chongqing University, Chongqing, 400000, China

20206154@cqu.edu.cn

Abstract. Engines are very important for human-beings and it is necessary for people to find a perfect kind of engines since they are used in many vehicles. In this paper, it will mainly focus the traditional engines and the hybrid engines, and compare there main performances including economical performance and environmental performance. For economical performance, researches have found that hybrid engine has higher thermal efficiency and lower thermal efficiency loss compared with traditional engine because hybrid engine does not have the inherent defect of crankshaft linkage mechanism as traditional engine. Also, since hybrid engine is consist of both electric motor and internal combustion engine, consequently it will have lower fuel cost. For environmental performance, hybrid engine not only reduce the consumption of non-renewable fuel but also more environmental since using electric to give vehicles power is relative environmental than using fuels only like traditional engine. This paper also find that both traditional engine and hybrid engine have development prospects in the transportation industry.

Keywords traditional engines; hybrid engines; performances; comparison

1. Introduction

With the development of economy and the technology, vehicles have become one necessary part of humans’ daily lives. It is universally known that engines are the conditions to move the car so that choosing a suitable engine for one car is important. Consequently, whether the performance indicators of the engines are reasonable will influence the power performance, fuel economy and the manufacturing cost of the cars and the related service life of the parts. As a result, it is important to choose the performance indicators of engines reasonably[1].

In the world there exist three main engines: the first one is traditional engine, which is one kind of Internal Combustion Engine (ICE); the second one is pure electric engine which is also called electric motors(EMs); the third one is hybrid engine, which has a system named hybrid-electric propulsion system (HEPS). HEPS can take advantage of the synergy between the two technologies by using both internal combustion engines (ICEs) and electric motors (EMs), each operating under its own optimal conditions[2]. According to researches, because the driving range of existing power batteries of pure electric vehicles is short and the cost is high, so its application areas are mainly limited to small vehicles and its market promotion process is very slow. As for fuel cell vehicles, they have not broken through the fuel cell technology and the resulting cost problems and it takes a long time for them to get market in a large quantities. Consequently, in the above context, the hybrid vehicle becomes the most industrialized and market-oriented models of electric vehicles since it uses the traditional engine and the electric motor[3]. As a result, hybrid engine is highly used in vehicles nowadays.

The performance indicators of the engine are used to characterize the performance characteristics of the engine and serve as the basis for evaluating the performance of various types of engines. At the same time, the establishment of engine performance indicators has also promoted the continuous improvement and innovation of the engine structure[4]. In order to find out the reasons why hybrid engines are better than traditional engines overall, this paper will discuss this question according to performances of these two engines. Firstly it will introduce their two performances that are economical performance and environmental performance, then it will compare them in these two aspects and finally give a brief discussion and a conclusion which one is better for human-beings to utilize. Also, it will give a future look on the engines.

2. Performances of traditional engines

2.1. Economical performance

For traditional engines, the economical performance will focus on the efficiency.

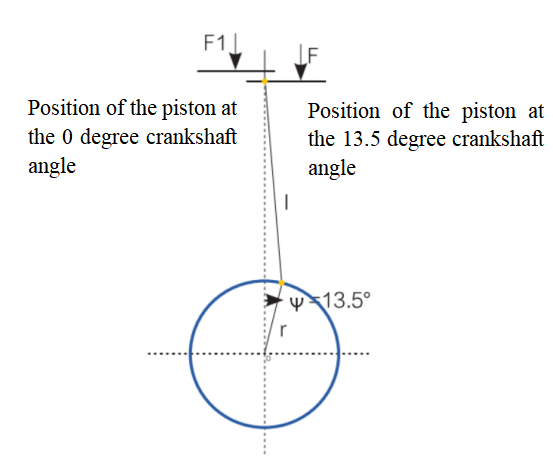

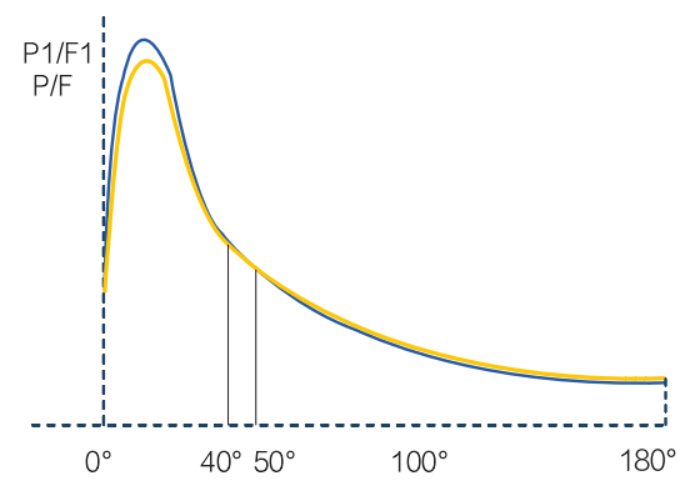

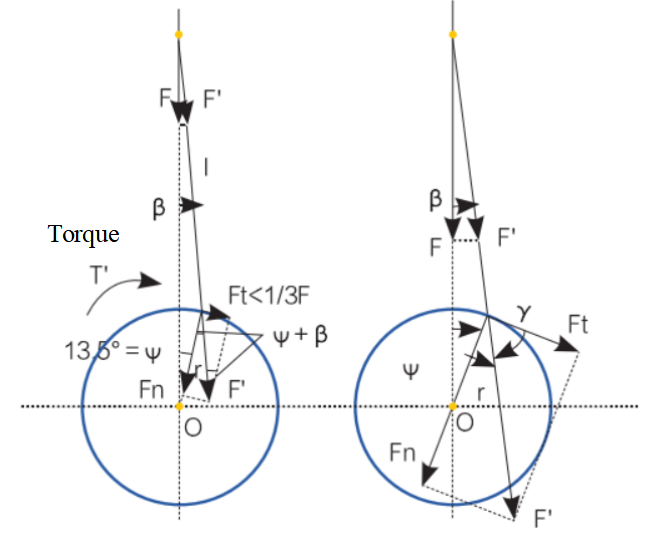

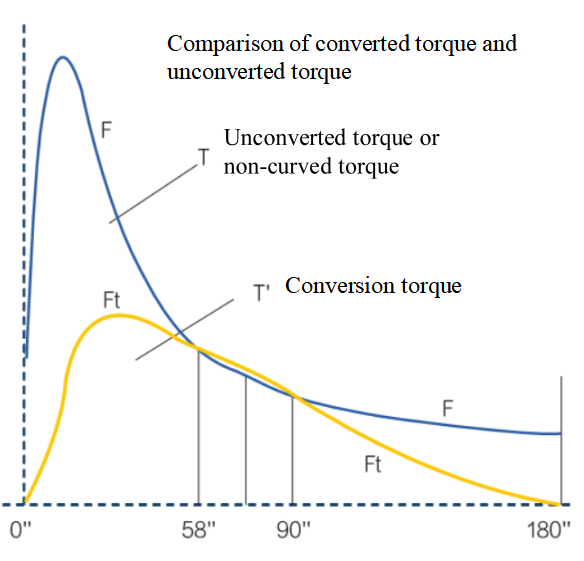

In the past hundred years, the biggest defect of the traditional engine is the inherent defect of its crankshaft linkage mechanism, which makes the traditional engine produce a large mechanical loss, as a result the thermal efficiency is also greatly reduced. The thermal efficiency loss caused by the crankshaft linkage mechanism consists of four parts, which are the maximum combustion pressure loss, combustion duration loss, the mechanical conversion loss in the mechanical process and friction loss during combustion. Figure 1 is the maximum combustion pressure loss in the combustion process, Figure 2 is the combustion duration loss, Figure 3 and Figure 4 is the mechanical conversion loss in the mechanical process[5].

The thermal efficiency of an engine is the product of the indicated thermal efficiency and the mechanical efficiency. For the indicated thermal efficiency, it depends on the indicator work, which depends on the combustion pressure in the cylinder; and the mechanical efficiency depends on the mechanical loss. This paper will talk about these two efficiency individually.

For indicating thermal efficiency, it is known that traditional engines require a maximum combustion pressure located between the 12 and 15 crankshaft angle of the stop point on the piston[6]. From Figure 1, if the maximum combustion pressure is located near the upper stop point, when the piston obtains the maximum expansion work, then the maximum piston force F1 at the 0 crankshaft angle is greater than the maximum piston force F at the 13.5 crankshaft angle. Secondly, the combustion duration of fuel combustion requires 50 or 60 crankshaft angle[6]. As shown in Figure 2, the yellow line is the piston pressure with long combustion duration, and the blue line is the piston pressure with short combustion duration. The shorter the combustion duration is, the greater the maximum combustion pressure will be. Since the combustion pressure drops quickly after the 15 crankshaft Angle, with the expansion work reduced together, some fuel has not been fully utilized, consequently it causes the loss of indicated thermal efficiency.

For the mechanical efficiency, traditional engines have two mechanical loss, one is the friction loss, another one is the mechanical conversion loss which is the sum of friction losses and the mechanical losses.

As shown from Figure 3, the force acting on the piston is decomposed into two through the rod, one is the tangential force Ft perpendicular to and pushes the crank, and the other is the radial force Fn that presses the crank and points to the crankshaft. The known moment = tangential force × arm radius, when the radius is constant, if the tangential force decreases, the moment decreases, the power also decreases, and the mechanical efficiency decreases. Because the radial force acts on the crankshaft through the compression of the crank, it produces small deformation and its high-frequency fibrillation to produce useless deformation energy, and finally causes the loss of mechanical conversion. This is the inherent defect of converting piston linear motion to crankshaft rotation motion.

In Figure 4, the crankshaft tangential force Ft forms a yellow line, and the freight forwarder force forms a blue line. It can be seen from the figure that the area formed by the blue line and the horizontal axis (i.e., the conversion or non-curve indication work) is significantly smaller than the area composed by the yellow line and the horizontal axis (i.e., the indication work of conversion), and the difference between the two areas is the mechanical conversion loss. The mechanical conversion loss is much greater than the friction loss, which is 75% of the effective thermal efficiency. Compared with the non-crankshaft linkage engine, the friction friction loss of the traditional engine is 20%, and the final non-crankshaft linkage engine is only 5% of the effective thermal efficiency[5]. Therefore, the mechanical loss caused by the crankshaft linkage mechanism engine is very huge.

Figure 1. Maximum combustion pressure loss[5].

Figure 2. Combustion duration of time loss[5].

Figure 3. Mechanical conversion loss (a) [5].

Figure 4. Mechanical conversion loss (b) [5].

2.2. Environmental performance

Traditional engines, namely internal combustion engines, still occupy the mainstream of the market and a large market share, so its energy conservation and emission reduction has also become the focus of world attention. Experts point out that if the traditional internal combustion engine reduces its fuel consumption rate by one gram, it can save millions of tons of fuel a year, based solely on China's existing car ownership[7].

It is known that traditional engines have caused a lot of environmental problems. The study found that pollution emissions are closely related to deflagration or rough, so that the engine is always subject to deflagration or rough restraint, which is the inherent defect of the crankshaft linkage mechanism. The direct cause of the known bad emission is mainly the long combustion duration and the uneven mixing gases, however, in order to avoid deflagration or rough, the combustion duration has to be extended and the uneven mixing gases have to be used[6]. The compression of gasoline engine is relatively low, mainly to avoid the combustion speed; diesel engine compression is relatively high, but to avoid rough. Consequently, producing the uneven mixing gases is the inevitable result. Also, long combustion time and uneven mixing gases and the local combustion temperature of high, low fluctuation and mixture thick, rare. These conditions will make it difficult to sufficient combustion, so that they provide a suitable breeding environment for pollution emissions [6], then resulting in high pollution emissions of traditional engines.

The fundamental cause of the bad emission of traditional engine is entirely in the deflagration or rough binding restriction, and deflagration or rough is the inherent defect of the crankshaft connecting rod mechanism. Because this structure is difficult to meet the necessary and sufficient conditions of combustion, so it is difficult for the traditional engine to fully burn. If there is no crankshaft linkage mechanism, then there is no pollution emissions from the crankshaft linkage mechanism, as a result the non-crankshaft linkage mechanism engine will have a very good exhaust performance[8].

3. Performances of hybrid engines

3.1. Economical performance

3.1.1. The impact of parking idling. Idle speed condition refers to a state in which the engine does not stall when the car is forced to stop temporarily, and only injects a small amount of oil to maintain the engine itself running at a low speed and does not do external work. Therefore, under the idle speed conditions, all the energy of the engine is consumed on the mechanical loss. With the increase of parking idle times and the extension of time, the consumption will be more.

According to statistics, a large diesel engine consumes 3.785L of fuel in 1h of idle, since the idling time is about 30% to 40% of the entire cycle time. Consequently if a bus runs for 8 hours a day, then there is about 9 to 12 liters of idle fuel consumption . At the same time, about 30% of the fuel consumption is used at idle speeds, where the CO and HC emissions usually account for about 70% of the total emissions[9]. Therefore, for parking idle speed, high idle speed will increase the fuel consumption and cause unnecessary consumption; low idle speed will cause engine operation instability and even stall.

Hybrid engine in the parking idle this problem gives the perfect solution, it can separate energy and power management, when parking it can still let the engine work in the field of economy, not output but can convert energy into energy storage, in the future if necessary, or let the car shutdown and previously saved energy to drive the car. It can be seen that the hybrid engine can reward the idle speed as much as possible while maintaining the stability of the idle speed, and with the increase of idle times and idle time, the hybrid engine-type cars have more obvious advantages in economic performance.

3.1.2. The impact of working efficiency. The power sources of hybrid electric vehicles are engine and motor, and the smaller power engines are selected through the control strategy, so that most of the working points can fall in the efficient range of the engine. At low speed and low load, if the motor can meet the required power, then the motor is driven alone to achieve pure electric mode; if the motor can not meet the required power, then start the engine and control the engine in the efficient working area, the remaining power for the battery, to improve fuel utilization. When the car accelerates and climbs sharply, and the engine can not meet the needs of the whole vehicle, the motor will participate in the work, so as to realize the motor power combined drive mode. Controlling the engine works in the efficient spare time, while controlling the engine works in the efficient area can improve the economy by 5% to 10%[9].

3.2. Environmental performance

As the environmental pollution is growing and the oil resources are falling dramatically, scientists are thinking about using other engines to replace traditional engines. As a result, the hybrid engine consisting of an internal combustion engine and an electric motor is proposed.

For the traditional hybrid vehicle, it has two sets of power sources, that are the thermal power generated by the traditional internal combustion engine and the electric power generated by non-rechargeable batteries. Taking the series hybrid electric vehicle as an example, the traditional hybrid engine is equivalent to directly adding a motor on the traditional engine, which allows the car to realize the following three power modes: the first kind is that the motor drives the battery to charge with the battery; the second kind is that the internal combustion engine directly provides the power needed by the car; the third kind is that the internal combustion engine and the battery pack provide the power together. The power output mode can be controlled according to different situations, consequently the engine has always been working in the area with the best comprehensive performance, which is the area with the lowest fuel consumption and the least pollution, so that it can achieve energy saving and emission reduction[10-12].

Although such hybrid vehicles are more energy-efficient and environmentally friendly than traditional internal combustion engines, their batteries are only an auxiliary power system, requiring internal combustion engines to charge it, so they cannot be separated from their dependence on oil resources.

On this basis, there is another kind of improved hybrid vehicles, called Plug-in Hybrid Electric Vehicles (PHEV). This vehicle can both refuel and charge hybrid cars, it will firstly choose the battery to power the car, if the battery power reaches the specified lower limit, then the vehicle will open the internal combustion engine to supply power. As a result, it needs a large battery to supply the power . Plug-in hybrid electric vehicles can save more energy and reduce more emissions than traditional hybrid electric vehicles. Also, plug-in hybrid electric vehicles can use the external power grid to charge the vehicle power battery at night, which can not only improve the efficiency of the plant-electric engine set, but also reduce the use and dependence of fuel resources. Meanwhile, since the cost of electricity is lower than the cost of oil combustion, so that it also reduces the use cost of cars. At the same time, the plug-in hybrid electric vehicle is powered between the traditional hybrid and pure electric vehicles, which means in a shorter driving journey vehicles can only depend on pure electric to be driven; in a longer driving journey, vehicles can maintain a normal driving over long distances by mainly using internal combustion engine and auxiliary using motor to drive. Finally, the plug-in hybrid electric vehicles have the advantages of low noise and low emission of the pure electric vehicles, and also have the characteristics of high power of the traditional engine vehicles[10,13].

4. Comparison and Discussion

In order to find out whether traditional engines or hybrid engines are better to be used in transportation industry, it is necessary to compare their corresponding performances. Besides, after finding a better one of the two engines, this paper will discuss what the problems still need to be faced and where the engines can still be improved in the future.

4.1. Economical performances comparison

First of all, the basic reason why the efficiency of traditional engine is not high is the defects of its crankshaft linkage mechanism. In reality, the efficiency of traditional engine could be high, however it has the crankshaft linkage mechanism structure. As a result, if this structure does not exist, then it will does not have the thermal efficiency loss. Consequently, if one engine does not have the crankshaft linkage mechanism structure, then it will have a chance to possess giant high efficiency potential.

In terms of parking idle, idle condition is one of the main working conditions of the engine, because the hybrid engine type car can separate energy and power management, and the traditional engine car can idle only through fuel to produce many consumption, so the hybrid cars can surpass the traditional internal combustion locomotive in terms of economic performance.

In terms of working efficiency, it is known that the engine has high average efficiency at high load rate and medium and high rotational speed. However, the power source of the traditional car is only the traditional engine, and the car runs at low load in most cases, so the economy and emission of the engine are poor. In contrast, hybrid cars, because it chose a smaller power engine, even at low speed and low load, if the motor to meet the demand of power, then can pure electric mode, if the motor to meet the demand of power, it can in some engines cannot meet the demand of motor power joint drive mode, thus fuel-saving, makes the economy increased.

According to these aspects, the economical performance of hybrid electric engine is better than the economical performance of traditional engine. However, there also exist some additional loss of hybrid engine. Since hybrid engine is consist of engine and electric motor, it is powered by the engine, and the process of driving the generator working is actually a process of secondary energy conversion. It is transformed from thermal energy into mechanical energy and then stored into electric energy from the battery to the motor and finally converted into mechanical energy. Therefore, it has the loss of power generation efficiency, battery charge and discharge efficiency and motor drive efficiency.

4.2. Environmental performances comparison

From the above content, for traditional engine, it only have internal combustion engine so that it will use more fuels to drive the vehicle, and then it will release more harmful emissions. Besides, both gasoline engine and diesel engine, in order to avoid deflagration or rough, they need to inhibit the combustion speed, which caused the gas being uneven mixed . Then, slow combustion speed will lead to long combustion time. After that, long combustion duration and uneven mixing gas will promote high local combustion temperature, low fluctuation and let the mixture become both thick and thin. At this time, it is difficult for fuels to burn completely, which provides suitable growth of breeding environment for pollution emissions, resulting in high traditional engine pollution emissions.

For hybrid engine, because it has two sets of power sources, so it can control the power output mode according to different situations. The result is that the engine has always been working in the area with the best comprehensive performance, which is the area with the lowest fuel consumption and the least pollution, so that it can achieve energy saving and emission reduction. Besides, except the traditional hybrid engine, the plug-in hybrid electric engine can both refuel and charge hybrid cars, Also, plug-in hybrid electric vehicles and it can use the external power grid to charge the vehicle power battery at night. Also, it reduces the use cost of cars since the cost of electricity is lower than the cost of oil combustion. At the same time, the plug-in hybrid electric vehicle is powered between the traditional hybrid and pure electric vehicles, which means vehicles can only depend on pure electric to be driven in a short term driving journey or maintain a normal driving over long distances by mainly using internal combustion engine and auxiliary using motor to drive. Finally, the plug-in hybrid electric vehicles have the advantages of low noise and low emission of the pure electric vehicles, and also have the characteristics of high power of the traditional engine vehicles.

It is obviously that hybrid engines are more environmental friendly than traditional engines from the above comparison. However, restricted by the lack of core technology, the lack of infrastructure construction and the cost pressure,though new energy engines such as hybrid engines have great potential in energy conservation and emission reduction, the dominant position of traditional engines in the market cannot be changed in a certain period of time. Therefore, it is very necessary and important to discuss the environmental protection of traditional engines (which are also named internal combustion engines) and enhance the environmental protection of their energy conservation and emission reduction. While the development of new energy vehicles is in full swing, the traditional engines have also begun to become more environmentally friendly and more energy-saving. As early as the end of 2009, Guangxi Yuchai and Tianjin University jointly launched two low-carbon, energy-saving and efficient engines that have achieved two-stage supercharging. One of them has been successfully installed and put into trial operation, realizing low-carbon emission, energy saving and motivation application miniaturization. Each car reduces at least 5 tons of carbon dioxide emissions per year. According to the authority statistics, at the end of 2009, the national number of trucks is nearly 13.7 million, if all installed this energy-efficient engine, it can reduce the annual carbon dioxide emissions by 68.5 million tons[7]. Therefore, the environmental protection performance of traditional engines has a huge space for development.

5. Conclusion

In order to find a good kind of engines in vehicles that can be used in transportation industry, this paper gives the comparison between traditional engines hybrid engines. It mainly compares their economic and environmental performances of these two kind of engines.

As for economical performances, due to the inherent defects of crankshaft linkage, the thermal efficiency loss of traditional engine is large and the mechanical efficiency is lower than that of hybrid engine. At the same time, in the aspect of parking idle speed, the hybrid engine cars can separate energy and power management, while the traditional engine cars can idle only through fuel to produce many consumption. Also, the hybrid vehicle fuel consumption is small, and the cost of electricity drive is lower than the fuel combustion drive. In terms of work efficiency, the power source of the traditional car is only the traditional engine, and the car is running at a low load in most cases, so the engine economy and emissions are poor. On the contrary, even if the hybrid vehicles operate at low speed and low load, if the motor meets the power demand, then it can be driven in pure electric mode. If the motor meets the power demand, hybrid engine can be driven by both the motor and the internal combustion engine, thus it saves fuels and increases the economy. As a result, the economical performance of hybrid electric engine is better than the economical performance of traditional engine.

As for environmental performances, for traditional engine, because it only have internal combustion engine so it will use more fuels to drive the vehicle and release much more harmful emissions. Besides, in order to avoid deflagration or rough, it needs to inhibit the combustion speed, which causes the gas being uneven mixed. Finally, long combustion duration and uneven mixing gas will make fuels become difficult to burn completely, which provides suitable growth of breeding environment for pollution emissions, resulting in high traditional engine pollution emissions. For hybrid engine, because it has two sets of power sources, so it can always work in the area with the best comprehensive performance, which is the area with the lowest fuel consumption and the least pollution, so that it can achieve energy saving and emission reduction.

Consequently, it is obvious that hybrid engine is better than traditional engine according to these two performances. In the future, vehicles can be improved by using more environmentally friendly engine. As a result, refining hybrid engines is important. At the same time, restricted by the lack of core technology, the lack of infrastructure construction and the cost pressure,though hybrid engines have great potential in energy conservation and emission reduction, the dominant position of traditional engines in the market cannot be changed in a certain period of time. Therefore, it is very important to improve traditional engines and enhance the environmental protection of their energy conservation and emission reduction.

References

[1]. Wanxiang, Xu Mingheng. Study on the determination method of the main performance indicators of automobile engines [J]. Journal of Wuhan University of Technology: Transportation Science and Engineering edition, 2001,25 (4): 4.

[2]. Friedrich, C., & Robertson, P. (2015). Hybrid-electric propulsion for automotive and aviation applications. CEAS Aeronautical Journal, 6 279-290. https://doi.org/10.1007/s13272-014-0144-x

[3]. Na Pengfei. Research on engine matching for Hybrid cars [J]. Mechanical Engineering and Automation, 2010.

[4]. Liu Mingjia, Li Dongfang, Wang Hongying, etc. On the performance indexes of automobile engines [J]. Automotive Practical Technology, 2019 (1): 6.

[5]. Liu Zuchuan. Comprehensive question of the traditional engine efficiency system [J]. Time Automobile, 2021, 000 (005): 35-41.

[6]. Han Tongqun, Yao Shenghua, Yuan Jinliang, etc. Automobile Engine Principle [M]. Peking University Press, 2007: 189, 194, 219; 137.

[7]. Song Xuelian. Traditional automobile engine seeks the upper position of environmental protection [J]. China Economic Weekly, 2010,20 (No.550): 49-49.

[8]. Liu Zuchuan. Interpretation of the pollution emission and deflagration of traditional engines [J]. Time Automobile, 2021,000 (005): 42-44.

[9]. Chen Long. An Analysis of the Power Performance and Economy of Hybrid Electric Vehicle. Wuhan University of Technology, 2008.

[10]. Yan Peiru, Tao Yuanfang, Ye Qinglin, et al. Energy-efficient and environmentally friendly car —— plug-in hybrid electric vehicle [J]. Mechanical Engineering and Automation, 2015 (5): 3.

[11]. Chen Hongchang, Yang Jianhua, the classification and working principle of automotive hybrid technology [J]. Automobile GM, 2010 (4): 31.

[12]. Wu Shaojian, Tao Yuanfang. Concept and design scheme of Enhanced electric vehicle [J]. Mechanical Engineering and Automation, 2010 (5): 209-213.

[13]. Xu Yanmin. Plug-in hybrid electric vehicle related technology and prospects [J]. Electromechanical Engineering Technology, 2011 (12): 116-118.

Cite this article

Sun,Y. (2023). Comparative study on the performance of traditional engines and hybrid engines. Theoretical and Natural Science,5,647-655.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Computing Innovation and Applied Physics (CONF-CIAP 2023)

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Wanxiang, Xu Mingheng. Study on the determination method of the main performance indicators of automobile engines [J]. Journal of Wuhan University of Technology: Transportation Science and Engineering edition, 2001,25 (4): 4.

[2]. Friedrich, C., & Robertson, P. (2015). Hybrid-electric propulsion for automotive and aviation applications. CEAS Aeronautical Journal, 6 279-290. https://doi.org/10.1007/s13272-014-0144-x

[3]. Na Pengfei. Research on engine matching for Hybrid cars [J]. Mechanical Engineering and Automation, 2010.

[4]. Liu Mingjia, Li Dongfang, Wang Hongying, etc. On the performance indexes of automobile engines [J]. Automotive Practical Technology, 2019 (1): 6.

[5]. Liu Zuchuan. Comprehensive question of the traditional engine efficiency system [J]. Time Automobile, 2021, 000 (005): 35-41.

[6]. Han Tongqun, Yao Shenghua, Yuan Jinliang, etc. Automobile Engine Principle [M]. Peking University Press, 2007: 189, 194, 219; 137.

[7]. Song Xuelian. Traditional automobile engine seeks the upper position of environmental protection [J]. China Economic Weekly, 2010,20 (No.550): 49-49.

[8]. Liu Zuchuan. Interpretation of the pollution emission and deflagration of traditional engines [J]. Time Automobile, 2021,000 (005): 42-44.

[9]. Chen Long. An Analysis of the Power Performance and Economy of Hybrid Electric Vehicle. Wuhan University of Technology, 2008.

[10]. Yan Peiru, Tao Yuanfang, Ye Qinglin, et al. Energy-efficient and environmentally friendly car —— plug-in hybrid electric vehicle [J]. Mechanical Engineering and Automation, 2015 (5): 3.

[11]. Chen Hongchang, Yang Jianhua, the classification and working principle of automotive hybrid technology [J]. Automobile GM, 2010 (4): 31.

[12]. Wu Shaojian, Tao Yuanfang. Concept and design scheme of Enhanced electric vehicle [J]. Mechanical Engineering and Automation, 2010 (5): 209-213.

[13]. Xu Yanmin. Plug-in hybrid electric vehicle related technology and prospects [J]. Electromechanical Engineering Technology, 2011 (12): 116-118.