1. Introduction

Many developing countries have complex and diverse topography, with mountains, plateaus, basins, Hilly predominance The diverse terrain makes the contradiction of unbalanced and insufficient development of agricultural mechanization in developing countries increasingly prominent, and with the advancement of science and technology and the improvement of productivity, people are paying more and more attention to the application of UAV technology in the agricultural field [1]. Due to the increasing demand for food caused by the increasing population and the limited area of arable land, many farmers have to carry out agricultural activities in hills, mountains and even river beaches. These places have a complex topography, Mechanized planting agricultural machinery is difficult to work in the field, and the mud feet in the interweaving area of water network and flat lake are easy to trap [2]. Therefore, drone sowing has become the only choice for many farmers [3]. However, the softness and hardness of the soil in different regions are very different, and the traditional seeding drone often uses a large area of fly seeding to sow seeds, which not only causes a lot of waste of seeds, but also makes it impossible to sow seeds deep into the deeper soil layer under the condition that the soil is relatively arid, resulting in “half the effort”.

Therefore, the design and development of intelligent seeding systems has become a research hotspot for many researchers, because it can achieve sustainable agriculture, Smart agriculture and precision agriculture [4]. Today, we use machine tools and various technologies in almost all areas of agriculture, Drones play an important role in these technologies [5]. In this context, this paper designs a multi-functional seeding device carried by UAV, which can be applied to the dispersal of crop seeds in various terrains, such as soil slopes, hills, plains and other terrains. In the inter casting mechanism, the device is mainly composed of spraying mechanism, indirect broadcast mechanism, electromechanical control mechanism and material storage mechanism. The device can carry out large-scale and multi-angle dispersal with the assistance of UAVs, so that small seeds can quickly complete sowing; accurate and uniform interseeding, send large seeds into the soil to ensure their survival rate. This article is filtered by scenario, Mechanism design, Design calculations, Feasibility analysis was carried out by three-dimensional modeling and dynamic virtual simulation, and experimental tests were made to prove that the seed inter seeding was accurate, the spread spraying was uniform, and the coverage was large. The unit fulfills the intended design function in order to play a role in assisting agricultural sowing work.

2. Overview of current research

At present, UAV seeding is mainly based on spreading operations. The seeder is the seed. The most critical working part of the device can be divided into mechanical type. There are three types of pneumatic and centrifugal type. The mechanical seeder has simple structure, low processing accuracy and small cost, but has high requirements for seed size, and is easy to cause seed damage in the process of filling and arranging, and its operating speed generally does not exceed 4 due to the limitation of structural performance~7km/h. The pneumatic seed discharger does not have high requirements for seed type, is not easy to damage seeds, and has good versatility, but its processing accuracy is high, the structure is more complex, and the power consumption is large. Both have significant limitations. Although the centrifugal seeder inherits many advantages of the first two, it still has major shortcomings in sowing depth and accuracy [6]. At present, many UAV seeding devices are designed based on centrifugal seeders, but the actual seeding error can still reach 13%The above is only suitable for the sowing of high-density crops [1].

Compared with manual spreading, the uniformity of sowing by drones is improved, but there are the following disadvantages: the seeds are in the process of falling, It is easily disturbed by the rotor wind field, resulting in uncontrollable planting position and poor sowing uniformity; it is difficult to achieve the sowing effect of rows and holes, and the ventilation and permeability of crops in the later growth are poor, which is easy to breed diseases and pests, and is not convenient for field management; Spreading is only suitable for grass seed sowing in large pastures [7]. At the same time, according to studies, seeds that spread after sowing are easily preyed on by predators such as birds and mammals. The seeds are coated and pelletized, as drones Part of the seeding, may inhibit the activity of seed predators. However, despite success stories in laboratory conditions, there is still little about which substances can actually reduce the chances of seed predation in the field, or how to apply them to ensure that seeds are protected [8].

3. Research objectives and research content

3.1. Research objectives

In view of the above problems, this paper intends to design a multi-functional seeding device equipped with UAV, with AutoCAD, Solid works and other software as technical support, through simulation analysis, structural design and functional verification and other methods, to design a seeding device with high degree of automation, low cost, strong environmental adaptability and accurate and deep seeding to cope with the sowing requirements in various environments. Firstly, the existing spreading device is retained and the structure is optimized, and on this basis, the interval seeding mechanism and auxiliary water spray mechanism are installed.

3.2. Research content

In view of the above research objectives, the research content and implementation plan of this paper are determined as follows:

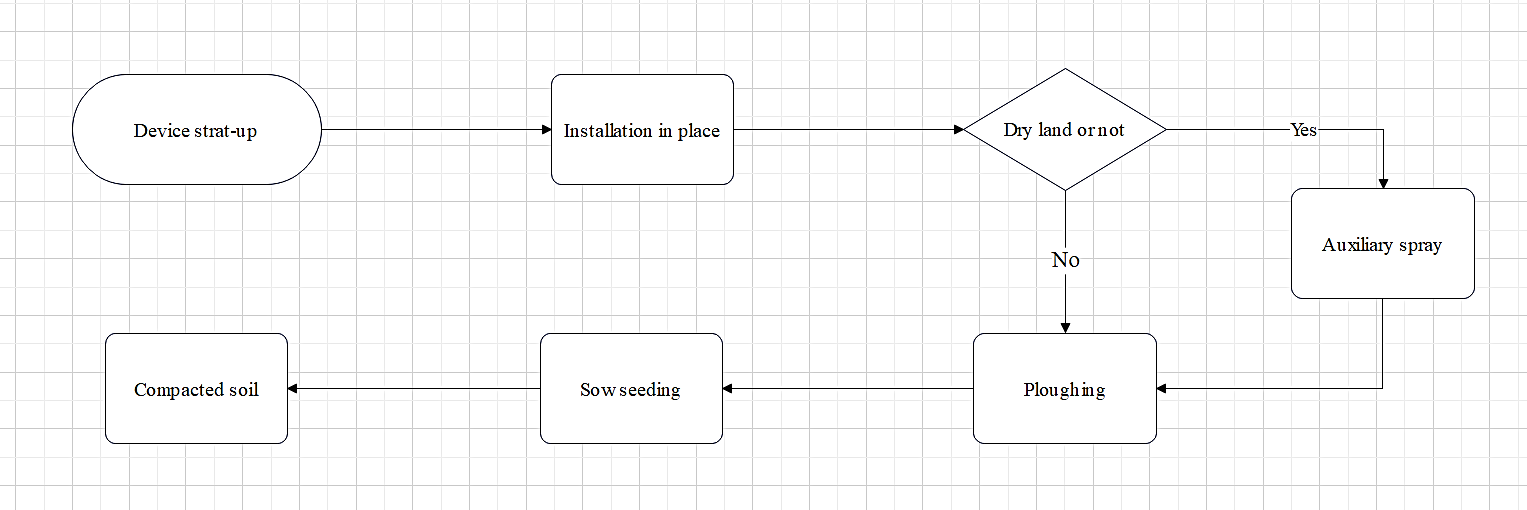

(1) Planning of work process. According to the requirements that need to be met by seeding UAVs and the current pain points, the UAV workflow is newly planned and the technical scheme is studied.

(2) Interval sowing mechanism design. First of all, determine the seeding process, determine its function of being able to accurately sowing seeds, and design the adjustable seeding mechanism that can be applied to most crop seeds, so that it can achieve a balance in efficiency, precision and lightweight. At the same time, theoretical analysis is carried out, a three-dimensional model is established, and its influencing factors are clarified.

(3) Auxiliary water spray mechanism design. In view of the special drought operation conditions that may be encountered by the seeding drone, a water spray system that can assist the seeding mechanism to soften the soil is designed, and the speed sensor can achieve the highest efficiency of water flow utilization.

(4) Material storage part design. Based on the structural dimensions and power parameters of the UAV working platform, considering the convenience of adding materials, the seed box and water tank that can be carried by the UAV are specially designed, and their volume, weight, material and other parameters are determined.

(5) Reliability analysis of key components. Force analysis of key components such as mounting integration plates, seed press-in mechanisms, etc., to further optimize the structure and materials.

4. Detailed design of the device

4.1. Overall structural design

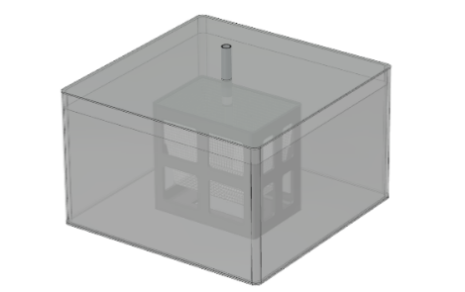

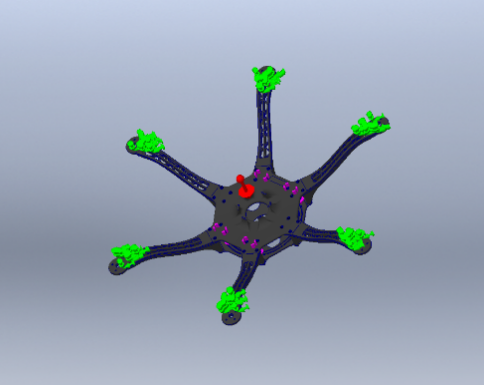

Figure 1. Schematic diagram of the structure of the seeding drone (Picture credit: Original)

The seeding device designed in this paper is mounted on the hexarotor UAV platform, which can complete the sowing operation of most crop seeds, and the whole equipment is composed of UAV, seeding mechanism, auxiliary water spray mechanism and material storage part. Its structure is shown in Figure 1. The main part of the drone is made of 7075 aluminum alloy, the material storage part is made of plastic, nylon and other composite materials, and the sprinkler head and control valve body of the seeding mechanism and auxiliary water spray mechanism are made of 2024 aluminum alloy. Specific cleaning process was shown in the Figure 2.

4.2. Device workflow

Figure 2. Device workflow diagram (Picture credit: Original)

4.3. Interval seeding mechanism design

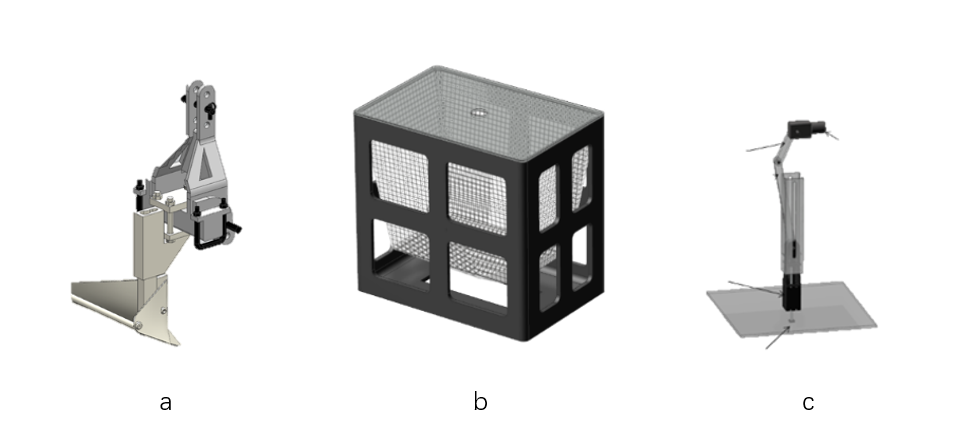

The interval sowing mechanism is mainly composed of a plow (as shown in the Figure 3.(a)), a motor, a seed funnel (as shown in the Figure 3.(b)), and a seed press-in structure (as shown in the Figure 3.(c)).

Figure 3. Plough (a). Seed box (b). Seed press-in structure (c). (Picture credit: Original)

The working principle of this interval seeding mechanism is as follows: first when the plow is inserted into the soil with the connecting plate and the cover soil plate downward, as the drone moves forward, ahead the plough separates the soil to form a planting soil trench, and at the same time the seeds in the seeding funnel fall from the tube into the seeding rotation plate, and the servo controls the seeding rotation plate to turn a certain angle, so that the seeds fall into the ploughed trench along the pipe from the hole in the inter seeding fixed plate, and finally the two covered soil plates that move forward with the plough cover the soil into the trench to complete the planting of seeds. As the drone continues to advance, the plow continues to open a ditch, the servo repeatedly swings at a certain time interval according to the system control, and the seeds falling from the seeding funnel are continuously moved to the hole to fall and plant, and the two cover soil plates connected behind also continue to advance to complete the cover soil work.

The interval sowing structure designed in this paper is simple, the plough and cover plate adopt an innovative connection integrated design, and then the seeds fall at more accurate intervals through the control of the divided rotating plate, realize isometric seeding, and then combine the adjustment of the UAV travel speed to achieve the control of the planting spacing. The entire process of digging, seeding and mulching is completed in one go. And by changing the size of the holes in the seeding rotation plate, that is, using different seeding rotating plates, the sowing of different seeds can be achieved.

4.4. Auxiliary water spray mechanism design

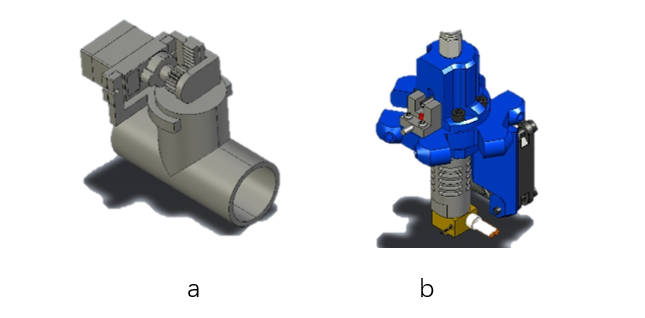

The auxiliary water spray mechanism consists of a control valve (as shown in the Figure 4.(a)), a waterway system and a sprinkler head (as shown in the Figure 3.(b)).

Figure 4. Control valve (a). Nozzle (b). (Picture credit: Original)

When the soil is relatively hard, the auxiliary water spray mechanism will spray out the water flow before the plough of the sowing mechanism to achieve the purpose of softening the soil, which is conducive to the excavation of the plow; at the same time, it can also provide a certain water source for the seed and improve its germination rate. In order to improve the utilization rate of water, the mechanism should be designed with a speed sensor, which can adjust the size of the valve according to the speed of the drone to adjust the size of the water flow, so that the water output is kept in a reasonable range.

4.5. Material storage part structural design

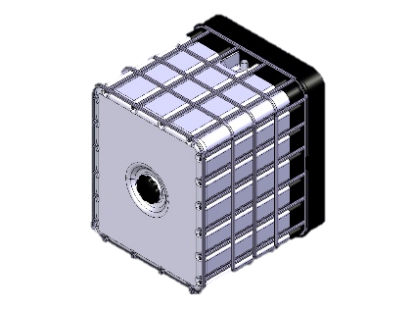

The material storage section consists of a seed box (as shown in the Figure 5.) and a water tank (as shown in the Figure 6.).

Figure 5. Seed box (Picture credit: Original)

As the loading structure of crop seeds, the performance of seed box directly determines the maximum sowing amount and sowing consistency.

The seed box designed in this paper is connected to the seed funnel, and the seeds fall into the funnel by its own gravity, so in order to ensure that the device can work normally in various slope terrain, the seed box is made of soft material, which is conducive to the seed can converge into the seed funnel at any angle, to ensure that there is no seed residue in the storage box, that is, there is no material dead zone.

The size of the seed box is also a trade-off. If the volume is too large, it is easy to cause the UAV load to be too high, which will lead to a series of problems such as shorter battery life and increased fatigue and wear of components; while too small the volume will easily cause frequent additions, which greatly reduces work efficiency. Therefore, the volume of the seed box should be maximally enlarged in compliance with the dynamic parameters of the drone and without affecting the work of the seeding device.

Figure 6. Water tank (Picture credit: Original)

The water tank is responsible for supplying water to the auxiliary sprinkler mechanism, and its volume size is the same as that of the seed box, and there is also a trade-off between weight and water storage. The water tank is placed on top of the drone, which not only makes room for the seeding device under the drone, but also makes it easy for users to refill water.

4.6. Reliability analysis of key parts

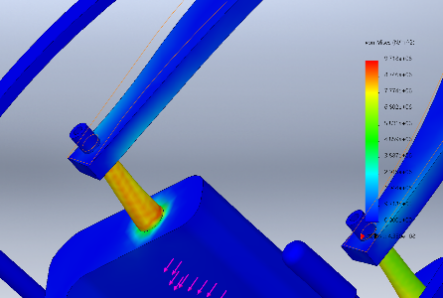

Figure 7. Mounting plate displacement cloud (Picture credit: Original)

Figure 7 showed the mounting plate displacement cloud. And, from the finite element analysis, it can be seen that the stress of the mounting plate is concentrated in the middle, and the deformation is concentrated in the edge, which is easy to brittle breakage, so we optimize the design of the mounting plate. Finally, Figure 8 showed the optimized mounting plate displacement cloud.

Figure 8. Optimized mounting plate displacement cloud (Picture credit: Original)

After discussion, we decided to strengthen the vulnerable part of the mounting plate by means of composite plate, and the finite element analysis of the optimized mounting plate is shown in the figure below. It can be seen from the finite element analysis diagram of the optimized mounting plate that the optimized mounting plate has uniform deformation and no concentrated stress, and the performance is significantly better than that of the bottom plate before optimization.

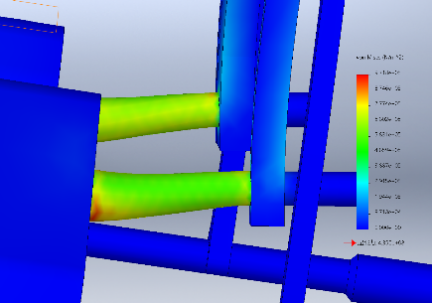

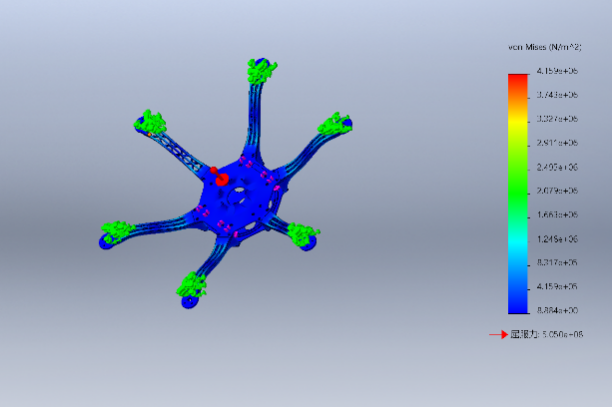

Figure 9. Load distribution simulation (Picture credit: Original)

In the simulated load, the frame material of the UAV was selected as the commonly used 7075 aluminum alloy, which fixed the six wing parts of the UAV, and then loaded 3 00N of static stress (vertical downward) and gravity (9.81N/kg) on its mounting plate. As shown in Figure 9.

Figure 10. Stress distribution diagram (Picture credit: Original)

From the static stress analysis, it can be seen that the structure of the UAV frame is still stable under the condition of 30kg load, and there is no obvious strain, which meets the requirements of use. As shown in Figure 10.

5. Application prospects

5.1. Evenly spaced sowing of large crops

Most of the agricultural drones on the market are mainly used to spread pesticides, and in terms of sowing is more of an incidental function, relatively simple, only suitable for the cultivation of small types of high-density cash crops such as wheat and soybeans. This type of crop has low requirements for sowing accuracy and seed depth penetration, so there is a lack of a drone product that can accurately sow seeds of large crops.

5.2. Sowing of arid hard land

In some areas where land hardening due to water scarcity, such as Northwest China, Nevada, Utah, southeastern California and Midwest Australia, when traditional drones sow seeds, the gravity of the seeds themselves cannot be brought into the soil, and the result can be imagined - it will inevitably lead to extremely low germination rates. Therefore, for drone seeding to have both speed and quality, a seeding device capable of sending seeds into hard soil is essential.

5.3. Sowing of paddy crops

Paddy fields are widely distributed around the world, with abundant paddy fields in eastern and southern Asia, as well as parts of Africa and South America. As we all know, traditional agricultural drones cannot sow seeds into the soil of paddy fields, and some seedlings and flowers in paddy fields bring considerable economic benefits, so the device can also improve the degree of automation in paddy field seeding, filling the gap in the area [9].

6. Discussion

In this paper, together with Professor Seno D. Panjaitan and others, they found the importance of agricultural drones in improving agricultural economic performance in developing countries and the lack of traditional agricultural drones in paddy field operations [10]. However, unlike the latter, this paper makes an in-depth study and gives solutions to the problem that traditional agricultural drones cannot accurately and deeply sow seeds.

Traditional UAV seeding devices mostly use rotational scattering or direct dumping of seeds, which has great defects in the sowing efficiency and cost of some large seeds. In this paper, while retaining the traditional seeding function, the precise interval seeding mechanism is newly designed. Compared to conventional seeding devices, this structure enables precise seeding and deep penetration of seeds that are large or need to be buried deep in the soil. At the same time, the device can first soak and soften the soil in hard soil, and then carry out accurate in-depth sowing to achieve a better sowing effect and improve the survival rate of crops.

The device may currently have the limitations of excessive weight, excessive requirements for UAV loading, complex desludge removal, and limited seeding rate. Therefore, in order to achieve better seeding results in the plant, subsequent work will be carried out in terms of material replacement, optimization, sludge removal mechanism and rate optimization.

7. Conclusion

The deep precision seeding device based on the UAV platform is an important supplement to the existing functions of agricultural seeding UAVs. In view of the fact that large-scale mechanized seeding equipment cannot enter hills, mountains and river beaches, it is particularly important to develop and use UAV platforms for deep and accurate seeding. Aiming at the pain points of traditional large-scale mechanized sowing equipment and traditional agricultural sowing UAV, this paper designs a multi-functional deep precision seeding device based on UAV platform, which consists of sowing mechanism, auxiliary water spray mechanism and material storage part, determines the basic structure and design parameters of the sowing system, proposes an interval sowing method, establishes a three-dimensional motion model, carries out simulation force analysis, verifies its function and analyzes its application prospects. Readers can continue to further study the mechanism design and material selection on the solutions of this article.

References

[1]. Amy J.C. Trappey, Ging-Bin Lin, Hong-Kai Chen, Ming-Chi Chen 2023. “A comprehensive analysis of global patent landscape for recent R&D in agricultural drone technologies.”, World Patent Information, 74.

[2]. Jin, L. F., Pu, J., Yang, W. B., Zheng, Y. H., Zhu, X. M. “Application of UAV in agricultural development.”, Intelligent agriculture guide, 19, 16-17.

[3]. S. Agrawal, P. Kathiria, V. Rawal, and T. Vyas 2022. “Drone Development and Embellishing It into Crop Monitoring and Protection Along with Pesticide Spraying Mechanism.”, in Smart Structures in Energy Infrastructure. 199-210.

[4]. M. E. Karar, F. Alotaibi, A. AL Rasheed, O. Reyad 2021. “A Pilot Study of Smart Agricultural Irrigation using Unmanned Aerial Vehicles and IoT-Based Cloud System.”, Inf. became Sci., 10(1), 131-140.

[5]. Kumar, M. Rani, Aishwarya, and P. Kumar 2022. “Drone Technology in Sustainable Agriculture: The Future of Farming Is Precision Agriculture and Mapping.”, Livestock Production and Aquaculture, 3-12.

[6]. Huang, X. M., Xu, H. M., Zhang S., Li, W. C., Luo, C. M, Deng, Y. F. 2020. “Design and experiment of a device for rapeseed strip aerial seeding-all databases.”, Transactions of the Chinese Society of Agricultural Engineering, 36, 78-87.

[7]. Chandra, A ., Biradar, N., Kumar, V ., Shivkurmar, A. M., Gopinath, R., Yajna, V., Devi, C. Lakshmi, Ramyashreedevi, G. S., Mahanta, S. K. 2022. “Possibilities and challenges of drone usage for grassland development-all databases.”, Journal Citation Reports, 43, 85-191.

[8]. J. Castro, F. Morales‐Rueda, D. Alcaraz‐Segura, and S. Tabik 2023. “Forest restoration is more than firing seeds from a drone,” Restoration Ecology, 31.

[9]. A. S. Azizul, D. El Pebrian, S. Mustaffha, S. M. Shamsi, Mohd. K. Zahari, N. A. Ruslan 2023. “The use of drone for rice cultivation in Malaysia: Identification of factors influencing its farmers’ acceptance,” Journal of the Saudi Society of Agricultural Sciences.

[10]. S. D. Panjaitan, Y. S. K. Dewi, M. I. Hendri, R. A. Wicaksono, and H. Priyatman, 2022. “A Drone Technology Implementation Approach to Conventional Paddy Fields Application,” IEEE Access, 10, 120650–12065.

Cite this article

Li,H. (2023). Design of precision seeding device based on hexarotor UAV platform and its application in hard soil. Theoretical and Natural Science,25,127-135.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Computing Innovation and Applied Physics

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Amy J.C. Trappey, Ging-Bin Lin, Hong-Kai Chen, Ming-Chi Chen 2023. “A comprehensive analysis of global patent landscape for recent R&D in agricultural drone technologies.”, World Patent Information, 74.

[2]. Jin, L. F., Pu, J., Yang, W. B., Zheng, Y. H., Zhu, X. M. “Application of UAV in agricultural development.”, Intelligent agriculture guide, 19, 16-17.

[3]. S. Agrawal, P. Kathiria, V. Rawal, and T. Vyas 2022. “Drone Development and Embellishing It into Crop Monitoring and Protection Along with Pesticide Spraying Mechanism.”, in Smart Structures in Energy Infrastructure. 199-210.

[4]. M. E. Karar, F. Alotaibi, A. AL Rasheed, O. Reyad 2021. “A Pilot Study of Smart Agricultural Irrigation using Unmanned Aerial Vehicles and IoT-Based Cloud System.”, Inf. became Sci., 10(1), 131-140.

[5]. Kumar, M. Rani, Aishwarya, and P. Kumar 2022. “Drone Technology in Sustainable Agriculture: The Future of Farming Is Precision Agriculture and Mapping.”, Livestock Production and Aquaculture, 3-12.

[6]. Huang, X. M., Xu, H. M., Zhang S., Li, W. C., Luo, C. M, Deng, Y. F. 2020. “Design and experiment of a device for rapeseed strip aerial seeding-all databases.”, Transactions of the Chinese Society of Agricultural Engineering, 36, 78-87.

[7]. Chandra, A ., Biradar, N., Kumar, V ., Shivkurmar, A. M., Gopinath, R., Yajna, V., Devi, C. Lakshmi, Ramyashreedevi, G. S., Mahanta, S. K. 2022. “Possibilities and challenges of drone usage for grassland development-all databases.”, Journal Citation Reports, 43, 85-191.

[8]. J. Castro, F. Morales‐Rueda, D. Alcaraz‐Segura, and S. Tabik 2023. “Forest restoration is more than firing seeds from a drone,” Restoration Ecology, 31.

[9]. A. S. Azizul, D. El Pebrian, S. Mustaffha, S. M. Shamsi, Mohd. K. Zahari, N. A. Ruslan 2023. “The use of drone for rice cultivation in Malaysia: Identification of factors influencing its farmers’ acceptance,” Journal of the Saudi Society of Agricultural Sciences.

[10]. S. D. Panjaitan, Y. S. K. Dewi, M. I. Hendri, R. A. Wicaksono, and H. Priyatman, 2022. “A Drone Technology Implementation Approach to Conventional Paddy Fields Application,” IEEE Access, 10, 120650–12065.