1. Introduction

The global shift toward sustainable transportation has positioned New Energy Vehicles (NEVs) as a critical solution for reducing carbon emissions and fossil fuel dependency. As the automotive industry transitions to greener alternatives, NEVs are increasingly recognized as the future of mobility. Central to this transformation are embedded systems, which enable essential functionalities such as battery management, energy optimization, fault diagnostics, and communication integration. These systems ensure efficient energy utilization, prolong battery life, and enhance vehicle safety through real-time monitoring and control. Despite their importance, current embedded system architectures and algorithms face significant limitations. For instance, insufficient computational efficiency hinders real-time operations, while centralized designs are vulnerable to single points of failure. Additionally, integrating diverse subsystems and achieving robust multi-sensor fusion remain challenging. The trade-offs between accuracy and performance in State of Charge (SOC) /State of Health (SOH) estimation models further highlight the need for more advanced solutions. Addressing these gaps is crucial for advancing NEV technologies and ensuring their widespread adoption. This paper aims to analyze the current state of embedded systems in NEVs, identify existing challenges, and propose innovative solutions. By focusing on key areas such as AI-driven algorithms, modular designs, and advanced communication protocols, this review provides a roadmap for future research and development in the field.

2. The role of embedded systems in NEVs

2.1. Defining embedded systems in NEVs

Embedded systems are specialized computing systems that integrate hardware and software to perform dedicated functions within larger systems. In the context of NEVs, these systems serve as the backbone for managing complex operations, combining sensors, microcontrollers, and algorithms to enable real-time decision-making [1]. Hardware components include processors, memory units, input/output interfaces, sensors, actuators, and power management units. Sensor arrays in NEVs incorporate lithium-ion battery voltage monitors (e.g., Texas Instruments BQ76952 with ±2mV accuracy), precision temperature sensors (e.g., Murata NXFT15XH103FA2B025 with ±0.5°C resolution), and Hall-effect current sensors (e.g., Allegro ACS723LLCTR-50AB-T for 50-200A dynamic range via 0.1mΩ shunt). Actuator subsystems feature high-speed contactors (e.g., TE Connectivity EV200AAANA for <8 ms battery disconnect at 500 VDC/200 A) and pulse-width modulated thermal management pumps (e.g., Bosch 0 392 020 030 for coolant flow regulation at 8 L/min@12 V). The software aspect encompasses firmware, control algorithms, and communication protocols, ensuring seamless functionality and adaptability to dynamic operating conditions.

In NEVs, embedded systems are integrated into critical subsystems, including Battery Management Systems (BMS), communication networks, fault diagnosis modules, and energy optimization frameworks. BMS, for instance, relies on embedded systems to monitor battery health, estimate SOC, and regulate charging and discharging cycles [2]. Communication networks such as FlexRay and the Controller Area Network (CAN) bus ensure reliable data exchange among vehicle subsystems. Meanwhile, while vehicle-to-everything (V2X) connectivity typically utilizes Dedicated Short-Range Communication (DSRC) and Cellular-V2X (C-V2X) protocols to enable autonomous driving and real-time traffic interaction [3]. Additionally, embedded systems play a vital role in fault diagnosis by detecting anomalies in real time and triggering corrective actions, thereby enhancing vehicle safety. Energy optimization is another key application, where adaptive algorithms dynamically allocate power resources to maximize efficiency and extend battery life. These diverse integration points highlight the indispensable role of embedded systems in NEVs, ensuring optimal performance across various operational domains.

2.2. The importance of embedded systems

The importance of embedded systems in NEVs stems from their ability to enhance efficiency, safety, and scalability. First, embedded systems optimize energy usage through adaptive algorithms that adjust power distribution based on real-time conditions. For example, advanced machine learning models integrated into BMS can accurately predict SOC, reducing energy waste and extending battery lifespan [4]. These optimizations not only improve vehicle range but also contribute to sustainability by reducing battery degradation. Second, embedded systems significantly enhance vehicle safety through real-time fault detection and emergency response mechanisms. By continuously monitoring sensor data, these systems can identify potential failures—such as thermal runaway in batteries—and initiate preventive measures, such as shutting down affected components or alerting drivers [5]. This capability is crucial for mitigating risks associated with high-voltage systems in NEVs. Finally, embedded systems support modular and scalable designs, enabling NEVs to adapt to evolving technological advancements. Modular architectures enable manufacturers to integrate new features without overhauling entire systems, reducing development costs and time-to-market [6]. For instance, Khaneghah et al. highlight the importance of fault detection and diagnosis (FDD) techniques in electric motor drives and battery systems, emphasizing how modular designs facilitate the incorporation of advanced signal analysis and machine learning methods for improved system performance. A key example of this modularity is the AUTOSAR framework, which standardizes software development, making it easier to incorporate innovations like AI and advanced communication protocols. This flexibility ensures that NEVs remain competitive in a rapidly changing market.

In summary, embedded systems are fundamental to NEVs, driving improvements in efficiency, safety, and scalability.

3. Application areas and case studies

3.1. Battery management systems

Embedded systems play a pivotal role in BMS for NEVs, particularly in accurately estimating critical parameters such as SOC and SOH. Advanced algorithms, including Kalman filtering and machine learning techniques like Long Short-Term Memory (LSTM) networks, have significantly improved SOC/SOH estimation accuracy. For instance, Khaneghah et al. highlight the importance of signal analysis and data-driven methods in fault detection and diagnosis, demonstrating how deep learning techniques enhance the robustness of SOC/SOH estimation under dynamic driving conditions [6]. Wang et al. further validate this approach, showing that a sparse learning machine can achieve an SOC estimation error below 1%, showcasing the robustness of deep learning in modeling complex battery behaviors. Such precision not only enhances battery lifespan but also reduces maintenance costs by enabling predictive diagnostics and adaptive energy management strategies.

Despite these advancements, challenges persist in real-world applications. One major limitation is the computational efficiency of embedded systems, particularly when processing complex multi-sensor data in real-time. Additionally, the integration of multi-sensor data often lacks robustness, particularly under extreme conditions such as high loads or low temperatures. For example, the error of Zhang et al.'s sparse learning machine is less than 1.5% in the low-temperature scenario, which is significantly better than the traditional method [7]. This highlights the need for more adaptive and resilient algorithms capable of handling dynamic operating environments.

3.2. Energy management and optimization

Energy management systems in NEVs greatly benefit from embedded systems, especially through centralized architectures that optimize power distribution across hybrid energy sources, such as batteries and supercapacitors. Centralized control enables efficient energy distribution, capturing excess energy during regenerative braking and redistributing it to maximize overall system efficiency [8]. Embedded systems also facilitate precise power allocation, ensuring balanced operation across subsystems and minimizing energy waste. However, choosing between centralized and distributed architectures presents a trade-off. While centralized systems offer superior control and high efficiency, they are vulnerable to single-point failures that could compromise overall reliability [9]. In contrast, distributed architectures enhance system resilience but introduce complexities in resource management and require more advanced communication protocols. For instance, Nissan has implemented embedded technologies to enhance its energy recovery systems, achieving notable improvements in efficiency. Nevertheless, challenges such as thermal management and the impact of extreme environmental conditions, such as high temperatures or humidity, highlight the need for cost-effective solutions that balance performance and resilience.

3.3. Communication protocols and integration

Embedded systems in NEVs rely on advanced communication protocols like FlexRay and real-time Ethernet to ensure seamless interaction among subsystems. These protocols support high-bandwidth, low-latency data transmission while providing reliable time synchronization, which is crucial for executing safety-critical tasks [10]. Furthermore, standardized software frameworks such as AUTOSAR enhance modularity and scalability, allowing manufacturers to integrate new functionalities more efficiently [11].

Despite their advantages, these communication protocols face practical challenges. While FlexRay is known for its deterministic performance and reliability, its adoption has been limited by its reliability, its adoption has been limited by its relatively rigid architecture and lack of scalability compared to Ethernet-based solutions. Similarly, real-time Ethernet struggles with large-scale integration, potentially compromising system stability in extensive NEV architectures [12]. Volvo’s implementation of Ethernet-based safety systems demonstrates the potential of optimized communication protocols to improve operational efficiency. However, the system’s performance under extreme load conditions still requires further refinement. Addressing these limitations will be critical for advancing communication technologies in future NEV platforms.

4. Challenges and contradictions in embedded systems

4.1. Centralized vs. distributed architectures

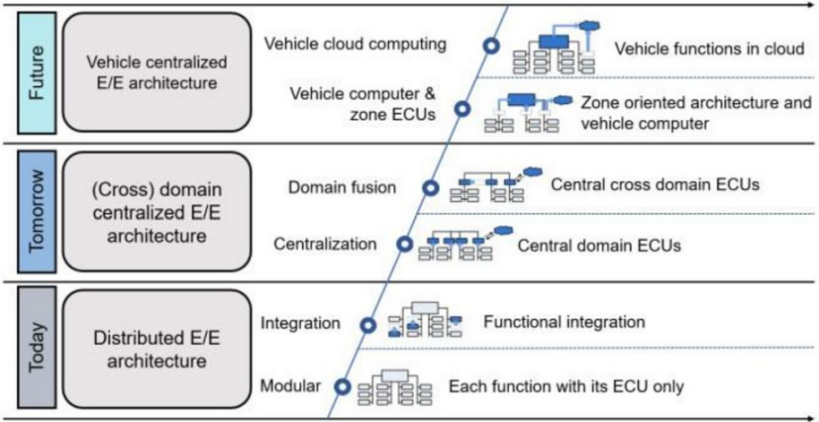

The architectural choice between centralized and distributed systems represents a fundamental challenge in embedded systems for NEVs. This section explores the trade-offs between these two approaches, highlighting their strengths and limitations. Centralized architectures, as depicted in Figure 1, in the tomorrow phase, rely on a single central processing unit (e.g., Central Meta Scheduler) to manage resources and decision-making. This approach excels in applications requiring real-time control, such as battery management and energy optimization. For example, Wang et al. demonstrated that centralized designs can reduce SOC estimation latency by 20% due to streamlined data flow [7]. However, their reliance on a single control node introduces single-point failure risks. A malfunction in the central processor could halt critical functions, such as thermal management or regenerative braking [9]. This vulnerability is particularly concerning in high-stakes scenarios like autonomous driving, where system reliability is paramount.

In contrast, distributed architectures (Figure 1, today phase) mitigate this risk by distributing tasks across multiple nodes, enhancing fault tolerance. Chaoui and Ibe-Ekeocha showed that distributed systems can isolate localized failures, ensuring continued operation of unaffected subsystems [11]. However, their complexity increases with scale, requiring advanced communication protocols (e.g., TSN over FlexRay) to synchronize nodes and minimize latency [3]. The trade-off becomes evident in energy management: while distributed systems improve reliability, their decentralized nature may reduce the precision of global resource allocation compared to centralized designs [3].

To address this contradiction, hybrid architectures (Figure 1) have emerged as a promising solution. Wang et al. proposed a hybrid framework combining centralized control for real-time critical tasks (e.g., SOC estimation) with distributed fault isolation modules [7]. This design reduced single-point failure risks by 40% while maintaining real-time performance, as validated by experiments on a prototype NEV platform. The hybrid approach aligns with the findings of Khaneghah et al., who emphasize the importance of integrating advanced signal analysis and machine learning techniques into fault detection and diagnosis systems, enabling efficient communication protocols and enhancing system robustness under dynamic operating conditions [6]. Figure 1 further clarifies the scenario-specific applicability of these architectures. Centralized systems are optimal for tightly coupled subsystems like BMS, where real-time decision-making is critical [2]. In contrast, distributed systems excel in complex, multi-node environments such as V2X communication, where scalability and fault tolerance outweigh minor efficiency losses [8]. This duality underscores the need for architecture selection to be guided by system-specific requirements, balancing performance, cost, and safety.

Figure 1: Centralized vs. distributed architectures [7]

4.2. Real-time performance vs. accuracy

Another significant contradiction lies in balancing real-time performance with estimation accuracy, particularly in SOC models. Traditional methods like Kalman filtering offer fast and reliable SOC estimates but may lack the precision required for advanced battery management systems [4]. On the other hand, machine learning-based models—such as LSTM networks—achieve higher accuracy by capturing complex, nonlinear relationships in battery data. However, these models often demand substantial computational resources, which can hinder real-time performance under high-load conditions. For instance, while Kalman filters operate with minimal latency, their reliance on linear approximations may lead to inaccuracies during rapid changes in driving conditions [5]. Conversely, LSTM-based models excel in dynamic environments but require powerful processors and extensive training datasets, increasing implementation costs. This trade-off necessitates careful consideration of application-specific requirements, ensuring that embedded systems strike an optimal balance between speed and precision.

4.3. Fault diagnosis complexity

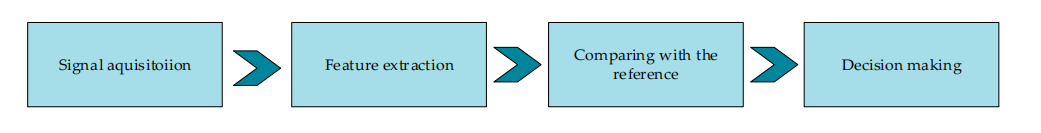

The inherent trade-off between algorithm complexity and system scalability in embedded FDD systems is exemplified by Figure 2, which delineates the workflow of signal-based fault detection and diagnosis methods [6]. The four-stage process–signal acquisition→feature extraction→reference comparison→decision making–provides a systematic framework for analyzing computational demands. Signal Acquisition: Raw data collection (e.g., current/voltage sensors) forms the foundation of the diagnostic chain. Traditional threshold-based methods operate directly on these signals with low latency, while advanced approaches like LSTM networks require preprocessing (e.g., noise filtering) that increases memory allocation [6]. The feature extraction phase determines algorithmic complexity. Deep learning methods (e.g., spectral feature extraction via LSTM) improve accuracy under dynamic conditions but incur higher computational costs compared to wavelet transform-based methods [6].

Reference Comparison & Decision Making: Khaneghah et al. validate a hybrid framework through [6]. Centralized reference libraries: Pre-trained fault signatures stored in secure cloud-edge systems; Distributed decision modules: Lightweight classifiers deployed on edge nodes; This design isolates computation-intensive tasks (e.g., feature extraction) from time-critical decision making, enhancing system robustness. Recent advancements focus on: stage-specific optimization: applying efficient algorithms (e.g., wavelet transforms) at the feature extraction stage; adaptive thresholding: dynamic adjustment of confidence levels based on operational conditions (e.g., battery SOC).

Figure 2: Workflow of signal-based fault detection and diagnosis methods [6]

5. Solutions and future directions

AI and machine learning are poised to revolutionize embedded systems in NEVs. AI-driven algorithms, such as those leveraging signal analysis and data-driven techniques like Neural Networks, Support Vector Machines, and Deep Learning, can enhance adaptive SOC and SOH estimation, enabling more precise battery management even under dynamic driving conditions [6]. For instance, Khaneghah et al. emphasize the importance of machine learning tools in fault detection and diagnosis for electric motor drives and battery systems, demonstrating their potential to improve system performance and robustness under varying operating conditions. For instance, Khaneghah et al. highlight the importance of machine learning tools in fault detection and diagnosis for electric motor drives and battery systems, demonstrating their potential to improve system performance and robustness.For instance, deep learning models such as LSTM networks have demonstrated superior accuracy in SOC estimation compared to traditional methods like Kalman filtering [4]. By integrating these models into embedded systems, NEVs can achieve real-time fault diagnostics with minimal latency, improving both safety and efficiency. Additionally, AI-based predictive maintenance can significantly reduce operational costs by identifying potential failures before they occur [5]. These advancements underscore the importance of continued investment in AI-driven architectures for NEVs.

The development of modular frameworks is another critical solution for current challenges in embedded systems. Modular designs allow manufacturers to build flexible systems that can be easily upgraded or adapted to new technologies. This approach not only reduces development costs but also enhances interoperability across different NEV subsystems. Furthermore, hybrid architectures that combine centralized control with distributed diagnostics offer a balanced solution. Centralized control ensures efficient resource management, while distributed diagnostics improve system robustness by isolating faults locally. Such designs are particularly beneficial for large-scale NEV platforms, where scalability and reliability are paramount. Advanced communication protocols are essential for ensuring seamless interaction among NEV subsystems. Hybrid protocols, such as FlexRay combined with real-time Ethernet, provide a promising solution for large-scale data exchange. These protocols offer high bandwidth and low latency, making them ideal for real-time applications like autonomous driving and V2X connectivity. However, ensuring cybersecurity remains a critical concern. As embedded communication networks become more complex, protecting them from cyber threats will require robust encryption and authentication mechanisms.

6. Conclusion

Embedded systems serve as the technological backbone of New Energy Vehicles, driving advancements in energy efficiency, operational safety, and intelligent functionality. By enabling precise battery management, adaptive energy optimization, real-time fault diagnostics, and seamless communication across subsystems, these systems ensure the reliability and performance required for modern electric mobility. Their integration into critical areas such as State of Charge estimation and vehicle-to-infrastructure communication underscores their indispensable role in achieving sustainable transportation goals. However, the evolution of embedded systems in NEVs faces persistent challenges. Architectural trade-offs between centralized and distributed designs reveal limitations in scalability and fault tolerance, while balancing real-time computational efficiency with estimation accuracy remains a critical hurdle. Additionally, the growing complexity of fault diagnosis algorithms and the integration of heterogeneous subsystems demand innovative solutions to maintain robustness without compromising performance. To overcome these barriers, future efforts must prioritize three key directions. First, leveraging artificial intelligence and machine learning can enhance adaptive algorithms for battery management and fault detection, enabling systems to dynamically respond to real-world driving conditions. Second, modular and hybrid architectures will bridge the gap between centralized control and distributed resilience, offering scalable frameworks for evolving vehicle technologies. Finally, advancing secure and standardized communication protocols is essential to ensure interoperability across global NEV platforms while safeguarding against cybersecurity threats.

By addressing these challenges through collaborative research and technological innovation, embedded systems will continue to redefine the capabilities of NEVs. Their ongoing refinement will not only improve vehicle efficiency and user safety but also accelerate the global transition toward cleaner, smarter, and more sustainable transportation ecosystems.

References

[1]. Zhang, Y., & Li, J. (2022) The technological innovation efficiency of China’s lithium-ion battery industry: A comprehensive review. Energy Reports, 8, 1234–1247.

[2]. Wang, X., et al. (2021) Advances in battery management systems for electric vehicles: A review. Renewable and Sustainable Energy Reviews, 145, 111029

[3]. Liu, H., & Chen, Z. (2020) Communication protocols for intelligent transportation systems: Challenges and opportunities. IEEE Transactions on Vehicular Technology, 69(10), 11456–11468.

[4]. Zhou, L., et al. (2021) Machine learning-based state-of-charge estimation for lithium-ion batteries: A review. Journal of Power Sources, 490, 229467.

[5]. Kim, S., & Park, J. (2020) Fault detection and diagnosis in electric vehicle battery systems: A comprehensive review.

[6]. Khaneghah, M.Z.; Alzayed, M.; Chaoui, H. Fault Detection and Diagnosis of the Electric Motor Drive and Battery System of Electric Vehicles. Machines, 2023, 11, 713.

[7]. Wang, W., Guo, K., Cao, W., et al. (2024) Review of Electrical and Electronic Architectures for Autonomous Vehicles: Topologies, Networking and Simulators. Automot. Innov., 7, 82–101.

[8]. Mamo, T., & Wang, F.-K. (2020) Long short-term memory with attention mechanism for state of charge estimation of lithium-ion batteries. IEEE Access, 8, 94140–94151.

[9]. Chaoui, H., & Ibe-Ekeocha, C.C. (2017) State of charge and state of health estimation for lithium batteries using recurrent neural networks. IEEE Trans. Veh. Technol., 66(10), 8773–8783.

[10]. Bian, C., He, H., Yang, S., & Huang, T. (2020) Stacked bidirectional long short-term memory networks for state-of-charge estimation of lithium-ion batteries. Energy, 191, 116538.

[11]. Zhang, L., Li, K., Du, D., Guo, Y., Fei, M., & Yang, Z. (2020) A Sparse Learning Machine for Real-Time SOC Estimation of Li-ion Batteries. IEEE Access, 8, 156165-156176.

[12]. Bhattacharjee, A., Verma, A., Mishra, S., & Saha, T.K. (2021) Estimating state of charge for xev batteries using 1D convolutional neural networks and transfer learning. IEEE Trans. Veh. Technol., 70(4), 3123–3135.

Cite this article

Lin,R. (2025). Applications and Challenges of Embedded Systems in New Energy Vehicles. Theoretical and Natural Science,109,166-172.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MPCS 2025 Symposium: Leveraging EVs and Machine Learning for Sustainable Energy Demand Management

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhang, Y., & Li, J. (2022) The technological innovation efficiency of China’s lithium-ion battery industry: A comprehensive review. Energy Reports, 8, 1234–1247.

[2]. Wang, X., et al. (2021) Advances in battery management systems for electric vehicles: A review. Renewable and Sustainable Energy Reviews, 145, 111029

[3]. Liu, H., & Chen, Z. (2020) Communication protocols for intelligent transportation systems: Challenges and opportunities. IEEE Transactions on Vehicular Technology, 69(10), 11456–11468.

[4]. Zhou, L., et al. (2021) Machine learning-based state-of-charge estimation for lithium-ion batteries: A review. Journal of Power Sources, 490, 229467.

[5]. Kim, S., & Park, J. (2020) Fault detection and diagnosis in electric vehicle battery systems: A comprehensive review.

[6]. Khaneghah, M.Z.; Alzayed, M.; Chaoui, H. Fault Detection and Diagnosis of the Electric Motor Drive and Battery System of Electric Vehicles. Machines, 2023, 11, 713.

[7]. Wang, W., Guo, K., Cao, W., et al. (2024) Review of Electrical and Electronic Architectures for Autonomous Vehicles: Topologies, Networking and Simulators. Automot. Innov., 7, 82–101.

[8]. Mamo, T., & Wang, F.-K. (2020) Long short-term memory with attention mechanism for state of charge estimation of lithium-ion batteries. IEEE Access, 8, 94140–94151.

[9]. Chaoui, H., & Ibe-Ekeocha, C.C. (2017) State of charge and state of health estimation for lithium batteries using recurrent neural networks. IEEE Trans. Veh. Technol., 66(10), 8773–8783.

[10]. Bian, C., He, H., Yang, S., & Huang, T. (2020) Stacked bidirectional long short-term memory networks for state-of-charge estimation of lithium-ion batteries. Energy, 191, 116538.

[11]. Zhang, L., Li, K., Du, D., Guo, Y., Fei, M., & Yang, Z. (2020) A Sparse Learning Machine for Real-Time SOC Estimation of Li-ion Batteries. IEEE Access, 8, 156165-156176.

[12]. Bhattacharjee, A., Verma, A., Mishra, S., & Saha, T.K. (2021) Estimating state of charge for xev batteries using 1D convolutional neural networks and transfer learning. IEEE Trans. Veh. Technol., 70(4), 3123–3135.